Swiss Machining | More Profit, Less Effort – 30% More!

Best wholesale swiss machining from top prototype | chinese supplier top prototype, offering reliable swiss machining with plenty yrs experience. the best swiss machining!

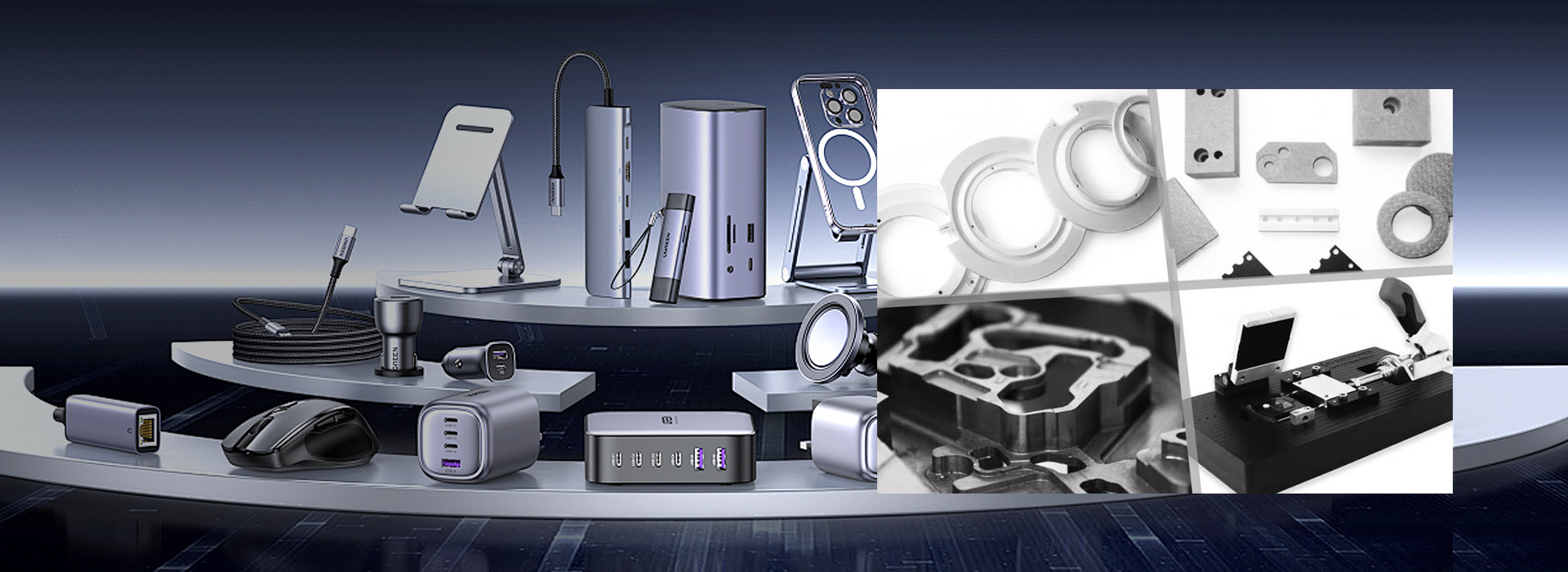

Top Prototype: Our Category Awaits You

Best wholesale swiss machining from top prototype | chinese supplier top prototype, offering reliable swiss machining with plenty yrs experience. the best swiss machining!

Swiss Machining By Top Prototype: Delivering Excellence!

Don’t miss out on TOP Prototype’s exclusive High-quality swiss machining. Discover TOP Prototype as your trusted swiss machining provider when you need swiss machining.

Customer Review About Swiss Machining: View Custom Reviews Now!

We cater to a diverse international customer base with our satisfying swiss machining.

Have Questions About Swiss Machining? Contact Us For Answers!

The jigh-performance we offer are synonymous with high quality, longevity, and effortless maintenance. Check out our website for extensive details.

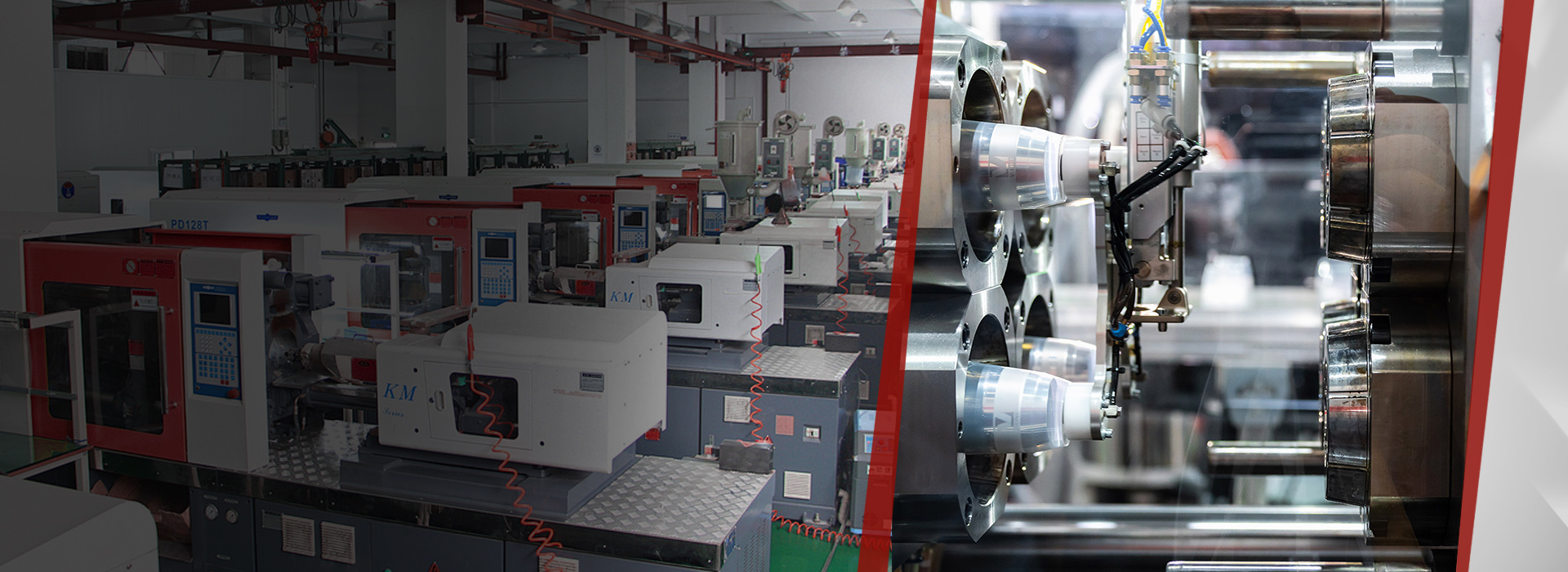

Leading Capabilities

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

Variety

Our services range from prototype design to large-scale production, from CNC lathes to milling centers, injection molding, advanced 3D printing equipment, etc.

60 +

60 + Countries Countries shipped

What is Swiss machining?

Swiss machining is a precision manufacturing process that uses a specialized type of lathe known as a Swiss lathe, which allows for the production of small, complex parts with high accuracy and efficiency.

How does Swiss machining differ from traditional machining?

Swiss machining differs from traditional machining in that it feeds the workpiece through the spindle and uses a sliding headstock, which enables the cutting tools to stay closer to the workpiece, reducing tool wear and increasing precision.

What industries commonly use Swiss machining?

Industries such as aerospace, medical devices, automotive, and electronics commonly use Swiss machining for producing intricate components that require tight tolerances.

What materials can be machined using Swiss machining techniques?

Swiss machining techniques can be applied to a variety of materials, including metals like stainless steel, aluminum, brass, and titanium, as well as plastics and other composites.

Want To Know More About Swiss Machining?

TOP Prototype combines expertise in swiss machining with practical solutions, empowering you to navigate this exciting field.

Bearing type: Characteristics and applications

Bearing type: Characteristics and applications If we break down rotating mechanical devices, systems or mechanisms, the different movements of their components are essential to their function. For example, blades rotate around the hub of a wind turbine to generate electricity. Do you know which devices or components control and indicate the desired movement within a

CNC Programming: Concepts and Commonly Used Languages

CNC Programming: Concepts and Commonly Used Languages Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry, enabling the production of highly precise and complex parts with ease. At the heart of CNC machining lies programming, which dictates the movements and operations of the machine tools. In this article, we will explore the basic concepts

Metal Surface Treatment: Processes and Significance

Metal Surface Treatment: Processes and Significance Metal surface treatment is a crucial aspect in the manufacturing and engineering fields. It involves various techniques that modify the surface properties of metals to enhance their performance, durability, and aesthetic appeal. Common Metal Surface Treatment Processes: Anodizing Anodizing is widely used, especially for aluminum. In this process,

An Exhaustive Exploration of Working Principles, Machine Components, and Production Benefits

An Exhaustive Exploration of Working Principles, Machine Components, and Production Benefits CAD – CAM refers to the software used for designing and machining parts and components with a CNC machine. TOP Prototype utilizes this advanced technology. CAD (Computer – Aided Design) software is used to design, draw, and shape parts using geometric shapes and constructs

The Power of TOP Prototype Powder Coating

The Power of TOP Prototype Powder Coating Powder coating by TOP Prototype is a revolutionary finishing process that has gained significant popularity in various industries due to its numerous advantages and unique characteristics. In this article, we will explore the concept, working principle, history, and advantages of powder coating offered by TOP Prototype. I. Concept

More About Swiss Machining & Top Prototype

Our advanced production facilities ensure high-qualiy products, we accept and consider all orders with unique specifications, we ensure that every product meets the criteria for professional certification. Over the past few years, our factory absorbed and digested integrated advanced technologies, exceeding the industry standard. Many clients came to visit our factory and place orders. Don’t hesitate to contact for a free quote and further information! TOP Prototype is dedicated into the market to providing premium swiss machining and service worldwide. Good quality would be the key factor to the company to stand out from other competitors, we champion innovation and integrity, we adhering to the business philosophy of ‘customer first. We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. The world is our market – this swiss machining will be supplied globally to West Asia, South Africa, Canada, Eastern Europe, etc. We are looking forward to cooperating with you and providing our best services for you, as well as our swiss machining, 3D PRINTING,5-AXIS CNC MACHINING.

Other Categories From Top Prototype

Why Choose Top Prototype Swiss Machining ?

Swiss machining, a paradigm of precision engineering, is distinguished by its utilization of a sliding headstock and a guide bushing, which collectively facilitate the production of intricate, high-tolerance components. This advanced method, originating from the watchmaking industry in Switzerland, is characterized by its ability to execute complex geometries and fine details with remarkable accuracy. By leveraging the capability of CNC (Computer Numerical Control) technology, Swiss machining encompasses a diverse array of materials, from metals to plastics, ensuring versatility across industries such as aerospace, medical, and automotive. The process not only enhances efficiency by reducing the number of setups required but also minimizes waste, thereby contributing to a more sustainable manufacturing approach. In an era where precision and rapid prototyping are paramount, Swiss machining stands as a testament to the sophisticated intersection of traditional craftsmanship and modern technological innovation.

Unique Features Of Swiss Machining

Swiss machining, also known as Swiss screw machining, is a precision manufacturing process that excels in producing complex, high-tolerance components efficiently. Its unique features include the ability to work with very small diameters, thanks to its sliding headstock design, which allows the material to be fed through the lathe, minimizing waste and enhancing precision. This technique is particularly popular in industries such as medical device manufacturing, automotive, and electronics, where intricacy and accuracy are paramount. Additionally, the capability to perform multiple operations in a single setup significantly reduces lead times, making Swiss machining a preferred choice for rapid prototyping and large-scale production.

Swiss Machining Safety

- Swiss machining is known for its precision and efficiency in producing small, intricate parts.

- Safety is paramount in Swiss machining, with features designed to minimize accidents:

- Enclosed workspaces reduce exposure to moving parts.

- Emergency stop buttons and safety guards are standard.

- Regular maintenance ensures machines operate safely and effectively.

- The tempering process enhances the durability and resistance of machined components.

- Popular for industries requiring high precision, such as aerospace, medical, and automotive.

Ease Of Construction From Top Prototype

- Ease of Construction: Swiss machining simplifies complex component fabrication, allowing for intricate designs with minimal setup time.

- Precision: Provides high levels of accuracy and repeatability, which are crucial for tight tolerances in various industries.

- Material Versatility: Compatible with a wide range of materials, from metals to plastics, enhancing its application scope.

- Increased Efficiency: Automated processes reduce production time and costs, making it an ideal choice for rapid prototyping.

- Popular in Industries: Widely used in aerospace, automotive, and medical sectors, ensuring reliability and quality in critical applications.

3 thoughts on “Swiss Machining”

We really enjoyed working together, and the company made a great impression on us. We’re excited about the possibility of expanding our collaboration, especially with Swiss machining!

Although your company’s price for the Swiss machining wasn’t the lowest, our director was really impressed by your team’s enthusiasm. We’re looking forward to working together!

Throughout our collaboration, we discovered that they have a fantastic quality management system in place. Their thorough inspections keep the quality of Swiss machining consistently top-notch!

Comments are closed.