In the world of 3D printing, SLA manufacturing holds a special place, especially in industries where extreme precision and fine detail are critical. One specific field is the medical industry, where precise, tailored, and biocompatible components may have a life-changing impact.

Among the numerous additive manufacturing methods, SLA manufacturing has become a preferred method for producing complex medical components with high-resolution and smooth surface finishes.

So, in this article, we’ll take a deeper look at SLA manufacturing in the medical industry, discussing its working principles, benefits, limits, and practical applications.

(Copyright Photo from: https://unsplash.com/photos/macbook-pro-beside-3d-printer-FB1vd3XT_zQ)

What Is SLA Manufacturing?

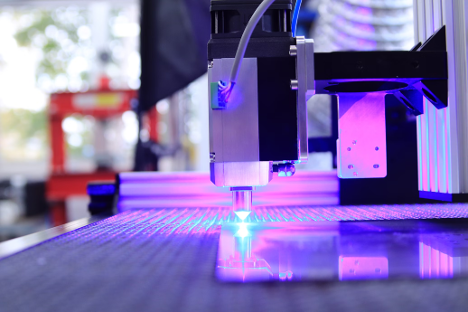

SLA manufacturing, also known as Stereolithography or SLA additive manufacturing, is one of the first and most advanced 3D printing processes. It is well-known for making high-precision prototypes and end-use parts with excellent details. The process employs photopolymerization, a method in which a liquid resin is selectively cured layer by layer using a UV laser.

How Does SLA Manufacturing Work?

The SLA process starts with a digital 3D model. A UV laser beam traces the pattern onto the surface of a vat containing liquid resin. When exposed to light, the resin hardens instantaneously, and the platform slowly lowers to allow the next layer to cure on top. This continues layer by layer until the entire item is produced. As a result, the process produces highly detailed components with smooth surfaces, making it ideal for delicate medical applications.

Pros and Cons of SLA Manufacturing in the Medical Industry

Like any technology, SLA manufacturing offers several advantages. However, it also has a few limitations that should be considered when applied to the medical industry. Here’s the breakdown:

(Copyright Photo from: https://unsplash.com/photos/purple-and-white-led-light-KshEaH06rV8)

Pros

- Exceptional Precision: SLA can achieve very fine resolutions, perfect for intricate anatomical structures and detailed prototypes.

- Smooth Surface Finish: Unlike many other additive processes, SLA parts require minimal post-processing.

- Customizability: Ideal for patient-specific applications such as prosthetics or surgical models.

- Fast Turnaround: SLA rapid prototyping allows for faster iterations for design validation or pre-surgical planning.

Cons

- Material Selection Limitations: SLA manufacturing uses resins, which can be photopolymerized. Other materials, like ABS or Nylon, would not be used because of non-photopolymerization.

- Degraded under the Sunlight: It is not recommended to use it for long-term outdoor exposure, although it is manufactured by UV lasers.

Applications of SLA Manufacturing in the Medical Industry

Though there are some disadvantages, the versatility and precision of SLA additive manufacturing make it a useful tool in various critical medical applications, such as:

1. Prosthetics and Orthotics

SLA allows for the creation of highly personalized prosthetics and orthotic devices tailored to individual anatomy. Its high precision ensures a snug fit and enhanced patient comfort.\

(Copyright Photo from: https://unsplash.com/photos/man-in-blue-crew-neck-shirt-holding-black-smartphone-J0XncLhc0vY)

2. Surgical Guides

Custom surgical guides allow surgeons to execute treatments with improved accuracy and safety. SLA’s fine resolution guarantees that the guides are properly contoured to fit the patient’s anatomy, reducing surgical mistakes.

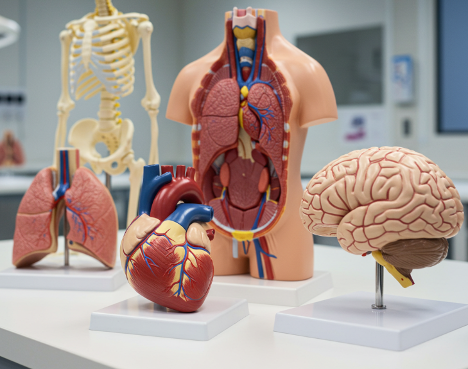

3. Anatomical Models

SLA manufacturing produces realistic anatomical models that help with medical training, surgical planning, and patient communication. These models offer lifelike textures and visual clarity to better understand complex conditions.

TOP Prototype: Provide Reliable SLA Manufacturing Production

At TOP Prototype, we understand the significance of precision and dependability in medical production. For that reason, our SLA manufacturing service produces high-resolution, smooth-finished prototypes and working models that fulfill the demanding medical industry standards.

As part of our SLA rapid prototyping solutions, we offer the following:

- Fast turnaround times to support tight project schedules

- A variety of medical-grade materials for specialized needs

- 24/7 detailed support for engineering

- Scalable production for both one-off prototypes and small-batch manufacturing

Whether you’re developing custom surgical tools or complex anatomical models, TOP Prototype combines speed and quality to help you bring your vision to life safely and efficiently.

Conclusion

SLA manufacturing has become an essential tool in the advancement of the contemporary medical industry. SLA additive manufacturing, with its unrivaled precision, flawless finishes, and quick delivery, is changing the way healthcare professionals design, plan, and execute medical procedures. And with the help of an experienced partner like TOP Prototype, you can keep your medical initiatives ahead of the competition.

Reach out to our experts by contact form to learn more!