The Crucial Role of CNC Machined Parts in the Medical Industry by TOP Prototype

The medical industry is constantly evolving, driven by the need for more precise, reliable, and innovative solutions to improve patient care and treatment outcomes. One of the key elements contributing to this progress is the use of CNC machined parts, and companies like TOP Prototype are playing a significant role in this arena.

Ⅰ. The Precision Demanded in Medical Applications

Medical devices and equipment require an extraordinary level of precision. In surgeries, for example, the smallest error in a component can have serious consequences for a patient’s health and well-being. CNC machining is renowned for its ability to produce parts with extremely tight tolerances.

It can accurately shape and size components to within micrometers, ensuring that they fit and function perfectly in medical devices. Whether it’s a tiny implantable part or a complex surgical instrument, the precision of CNC machining is essential. TOP Prototype understands this need for precision and has invested in state-of-the-art CNC machining technology and processes to meet the strict requirements of the medical industry.

Ⅱ. The Applications of CNC Machined Parts in Medical Devices

Implants and Prosthetics

CNC machined parts are widely used in the production of implants and prosthetics. These components need to be biocompatible and precisely crafted to fit the patient’s anatomy accurately. For instance, a knee implant must be designed and manufactured with great precision to ensure proper joint function and long-term durability. TOP Prototype has the expertise to produce high-quality CNC machined implants and prosthetics that meet the highest standards of quality and performance. Their parts are made from materials that are carefully selected for their biocompatibility and mechanical properties, providing patients with reliable and comfortable solutions.

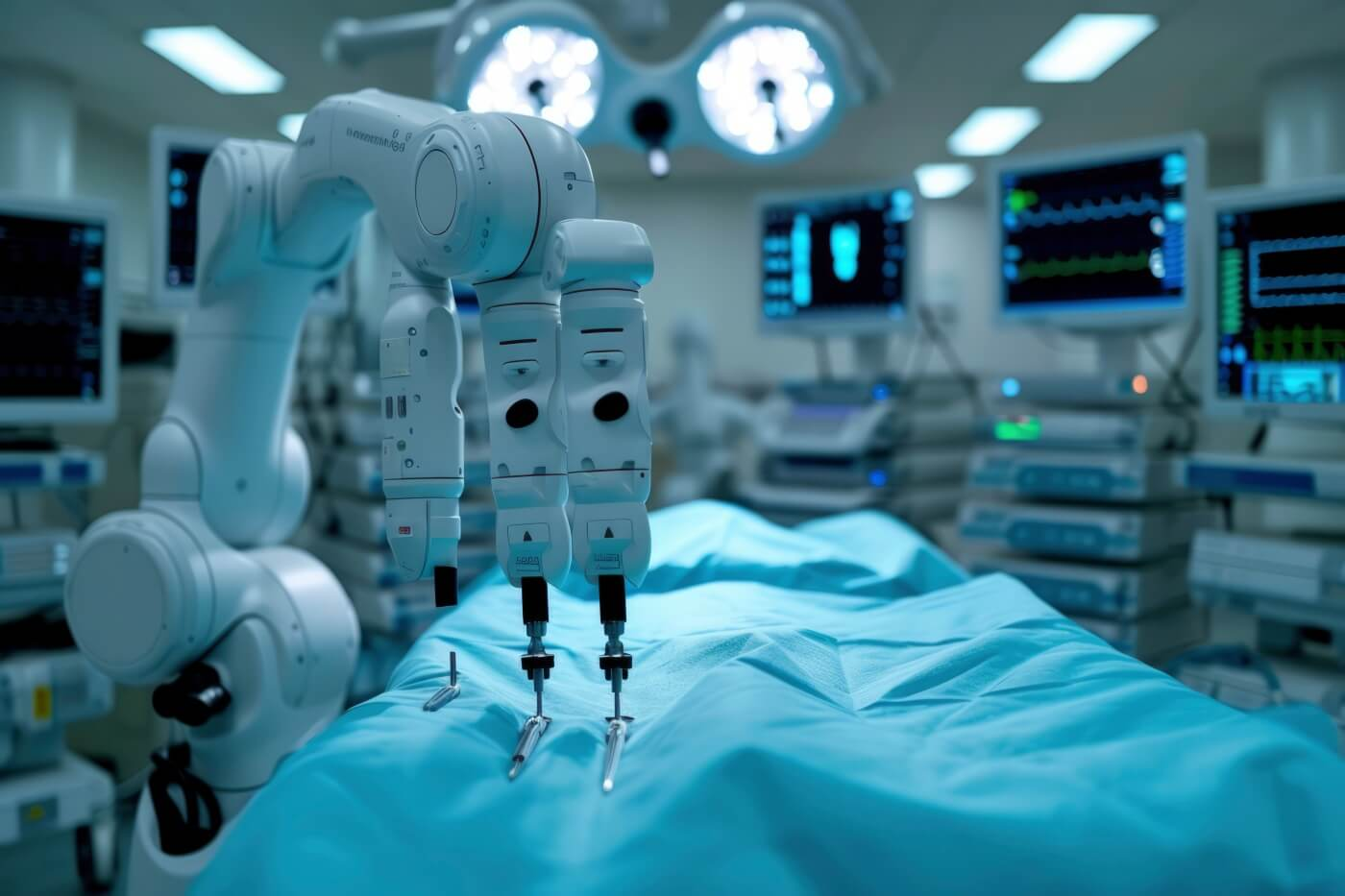

Surgical Instruments

Surgical instruments also rely heavily on CNC machining. The precision and durability of CNC machined parts are crucial for the effectiveness and safety of these tools. From scalpels with sharp and precise edges to complex surgical staplers, CNC machining ensures that each instrument functions flawlessly during surgeries. TOP Prototype manufactures a wide range of surgical instruments using CNC machining techniques, providing healthcare professionals with reliable tools that aid in accurate diagnoses and effective treatments.

Medical Imaging Equipment

In the field of medical imaging, such as CT scanners and MRI machines, CNC machined parts play a vital role in ensuring the accuracy and reliability of the equipment. These parts are used in the construction of the imaging components, such as the gantries and detectors, to ensure precise movement and accurate data acquisition. TOP Prototype’s CNC machined parts contribute to the high performance of medical imaging equipment, enabling doctors to obtain clear and detailed images for accurate diagnoses.

Ⅲ. The Quality and Compliance Standards of TOP Prototype

Stringent Quality

Control TOP Prototype places great emphasis on quality control. They have a comprehensive quality management system in place that monitors every stage of the CNC machining process. From the selection of raw materials to the final inspection of the finished parts, strict quality checks are carried out to ensure that each part meets the exacting standards of the medical industry. Their experienced quality control team uses advanced inspection equipment and techniques to verify the dimensions, surface finish, and material properties of the CNC machined parts, guaranteeing their reliability and safety for medical applications.

Compliance with Regulatory Requirements

The medical industry is highly regulated to ensure the safety and effectiveness of medical products. TOP Prototype is well-versed in these regulations and ensures that all its CNC machined parts comply with relevant standards such as ISO 13485 and FDA regulations. This commitment to compliance not only assures the quality and safety of their products but also enables them to serve customers in the global medical market. By adhering to these strict regulations, TOP Prototype helps medical device manufacturers meet the legal requirements and bring their products to market with confidence.

Ⅳ. The Innovation and Future Outlook

Continuous Innovation

TOP Prototype is constantly striving to innovate in the field of CNC machining for the medical industry. They invest in research and development to explore new materials, machining techniques, and design concepts. This innovation allows them to offer more advanced and customized solutions to their customers. For example, they are exploring the use of additive manufacturing in combination with CNC machining to create complex geometries and lightweight yet strong parts for medical applications.

Future Trends and Opportunities

As the medical industry continues to advance, the demand for CNC machined parts is expected to grow. With the increasing focus on minimally invasive surgeries and personalized medicine, there will be a need for even more precise and customized components.

TOP Prototype is well-positioned to capitalize on these trends. They are expanding their capabilities and collaborating with medical institutions and device manufacturers to develop new solutions that meet the evolving needs of the industry. In the future, we can expect to see TOP Prototype playing an even more significant role in the development of innovative medical devices and treatments through their high-quality CNC machined parts.

Conclusion

In conclusion, CNC machined parts are indispensable in the medical industry, and TOP Prototype has established itself as a leading provider of these critical components. Their commitment to precision, quality, compliance, and innovation makes them a valuable partner for medical device manufacturers and healthcare providers. As the medical industry continues to progress, TOP Prototype will continue to contribute to improving patient care and outcomes through the production of superior CNC machined parts.