Precision Redefined: CNC Machining for Automotive Camshafts by TOP Prototype

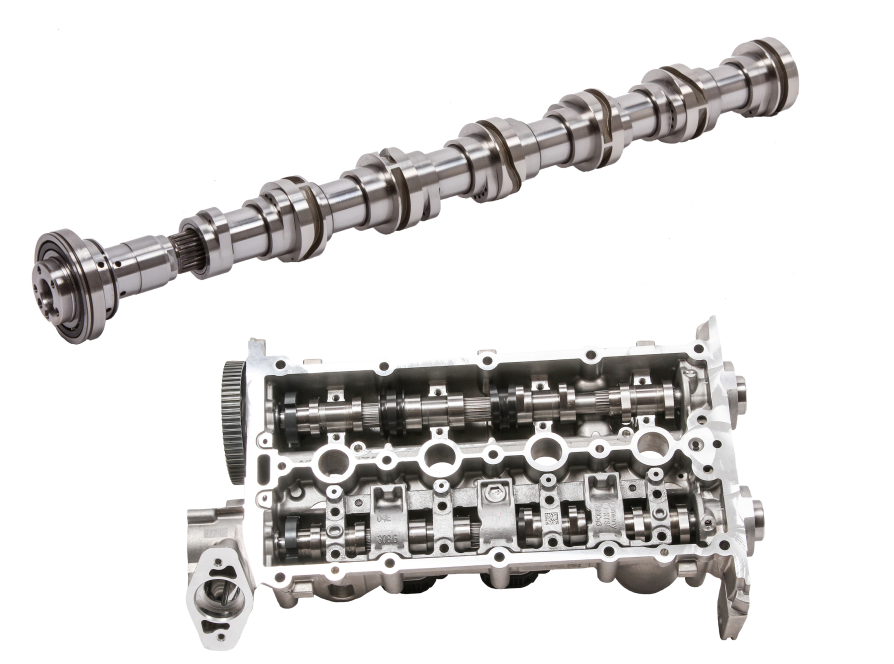

Every high- performance automotive engine has a core component: the camshaft. It acts as the “brain” of the valve train. It controls the timing and lift of engine valves. This directly impacts combustion efficiency, torque output, and overall engine performance. Advanced automotive engineering relies heavily on CNC (Computer Numerical Control) machining. CNC machining delivers unmatched precision and consistency for modern camshaft production. TOP Prototype is a leader in this field. It provides precision machining solutions that blend innovation and reliability for global automotive manufacturers.

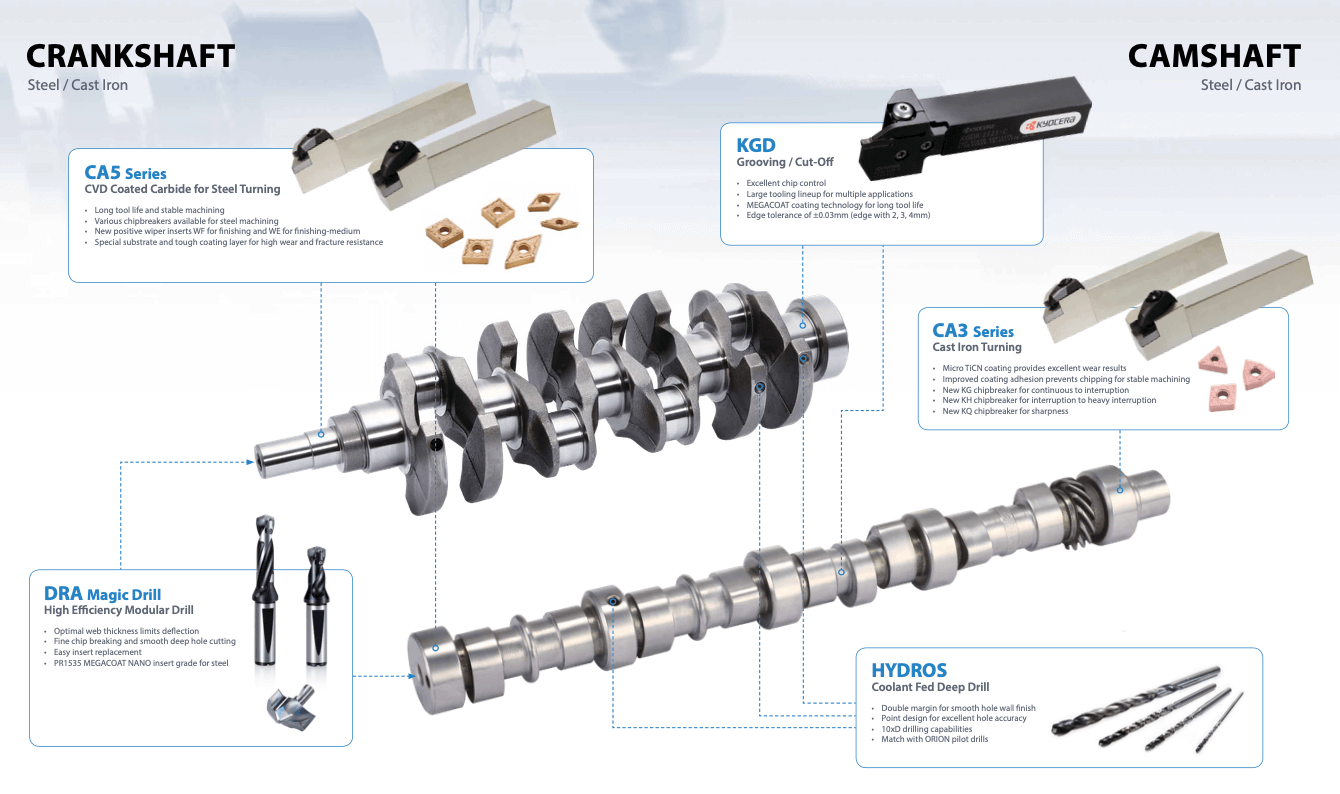

Why CNC Machining Is Indispensable for Camshaft Production

Automotive camshaft manufacturing demands exceptional engineering precision. Camshafts have complex structures. They require micron-level tolerances, unlike standard mechanical components. Even small deviations cause problems. These include reduced efficiency, increased noise, or premature wear. Such flaws are unacceptable in today’s competitive market. CNC machining solves these challenges with unique advantages:

– Computerized control systems eliminate human error. They ensure consistent precision across all components.

– Multi-axis machining handles complex lobe profiles, journals, and keyways in one setup. This shortens production cycles.

– It adapts to diverse materials, from alloy steels to titanium. It meets the needs of different engine types.

TOP Prototype’s Expertise: Elevating CNC Camshaft Machining to New Heights

TOP Prototype has refined CNC camshaft machining into an art. It combines state-of-the-art equipment with decades of engineering experience. The company offers end-to-end solutions. These cover every critical production stage, from design to delivery. It prioritizes customization and quality.

1. Design Optimization & Material Selection

TOP Prototype’s engineers use advanced CAD simulation tools. They optimize camshaft profiles before machining starts. These profiles align with specific engine performance goals. They suit compact hybrids and high-performance racing engines alike. Material selection is equally strict. Camshafts must resist extreme temperatures and mechanical stress. TOP Prototype’s facilities handle various materials easily, including:

– High-strength alloy steels. They offer balanced durability and performance for mainstream vehicles.

– QT700 ductile iron. It suits heavy-duty engines needing superior load-bearing capacity.

– Premium billet steel and titanium alloys. They create lightweight, high-performance racing camshafts.

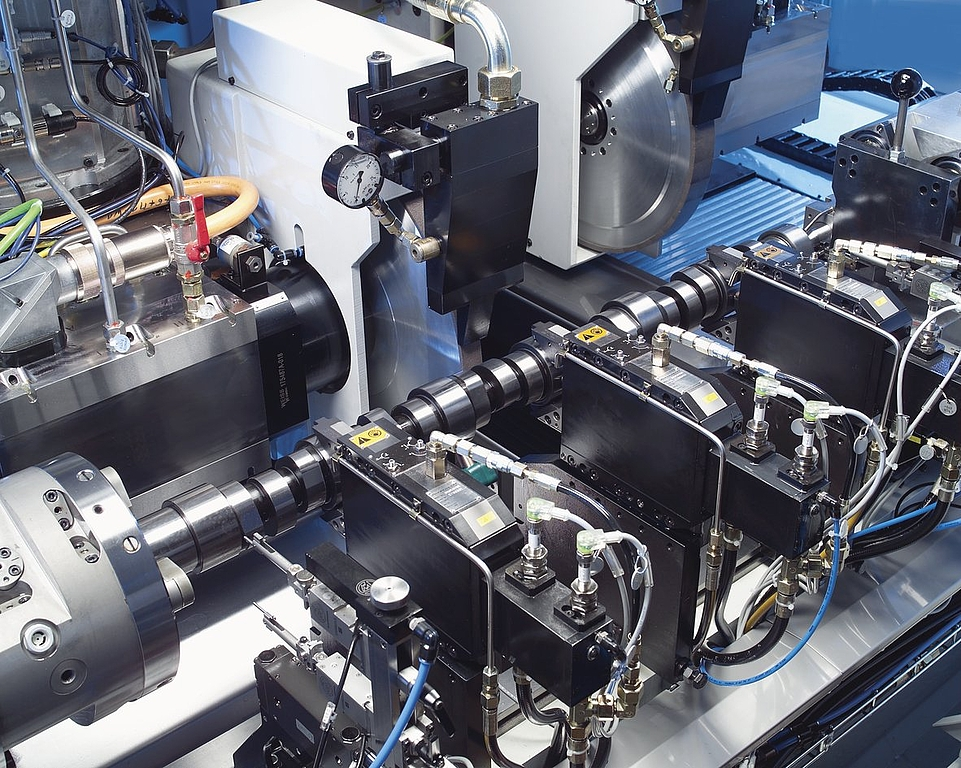

2. Advanced Machining & Grinding Technologies

TOP Prototype’s core strength lies in its cutting-edge equipment and processes. It moves beyond traditional manual grinding. The company uses 5-axis CNC machining centers. These process multiple camshaft features at the same time. Key technological advantages include:

– 5-axis machining maintains tight tolerances of ±0.02mm for cam lobe profiles. This precision is critical for optimal valve timing.

– Adaptive grinding systems feature real-time in-process gauging. They make dynamic adjustments to correct material variations.

– It reduces setup times and material waste. It delivers cost-effective solutions without sacrificing precision.

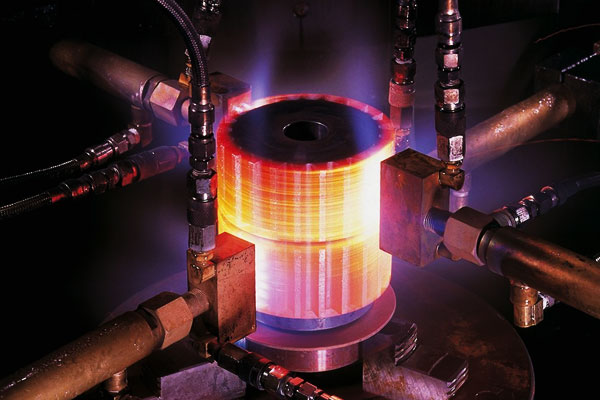

3. Heat Treatment, Finishing & Quality Control

TOP Prototype enhances camshaft durability and wear resistance. It uses precision heat treatment processes. These include induction hardening and nitriding. They target high-friction areas like cam lobes. After heat treatment, final CNC grinding and polishing follow. They create mirror-like surfaces to reduce friction.

Quality control is non-negotiable for TOP Prototype. It conducts rigorous inspections at every stage:

-Raw material testing ensures compliance with mechanical property requirements.

– In-process monitoring uses advanced tools. It detects and corrects deviations in real time.

– Final verification relies on coordinate measuring machines (CMMs) and laser profilometers. It guarantees micron-level accuracy.

Adapting to the Future of Automotive Engineering

Electrification and hybridization are reshaping the automotive industry. Yet demand for precision camshafts remains stable. Even hybrid powertrains need camshafts. They optimize internal combustion engine performance. TOP Prototype has adapted to these changes. It invests in cutting-edge CNC technology. It also expands its engineering capabilities to support next-generation engine designs.

The company offers great flexibility. It handles low-volume prototype runs and high-volume production batches. This makes it a trusted partner for automotive manufacturers. These include startups developing innovative powertrains and established OEMs scaling production. Beyond technical expertise, TOP Prototype adopts a customer-centric approach. It offers customized solutions. These balance precision, cost, and lead time. This approach has earned it a reputation as a reliable industry leader.

Conclusion: TOP Prototype—Your Trusted Partner for Precision Camshaft Machining

The camshaft is small but critical. It powers the modern automotive engine. CNC machining enables its precision. TOP Prototype leads this industry. It delivers high-quality, precision-machined camshafts. These meet the most demanding automotive standards.

TOP Prototype provides end-to-end solutions. They cover material selection, design optimization, multi-axis machining, and rigorous quality control. These solutions ensure every camshaft performs optimally. For automotive manufacturers aiming to boost engine performance, TOP Prototype is the ideal partner. It offers CNC camshaft machining that combines precision, reliability, and innovation.