Rapid Prototyping Cnc Milling | Industry Leaders

Top-quality rapid prototyping cnc milling in 2024 | leading chinese manufacturer top prototype. search top prototype, who provides quality rapid prototyping cnc milling. we devote to rapid prototyping cnc milling market for several yrs.

Category From Top Prototype

Top-quality rapid prototyping cnc milling in 2024 | leading chinese manufacturer top prototype. search top prototype, who provides quality rapid prototyping cnc milling. we devote to rapid prototyping cnc milling market for several yrs.

Rapid Prototyping Cnc Milling Boost Your Profit!

Choose from a wide range of Exceptional rapid prototyping cnc milling at TOP Prototype. TOP Prototype stands out for the rapid prototyping cnc milling, perfect for your rapid prototyping cnc milling needs.

Customer Feedback On Rapid Prototyping Cnc Milling: Don’T Miss Out!

Customers across the world choose our top-quality rapid prototyping cnc milling.

Interested In What Top Prototype Can Offer With Rapid Prototyping Cnc Milling? Contact Us Now!

Our trustworthy are known for their top-notch quality, durability, and straightforward maintenance. Visit our website for a deeper understanding.

Variety

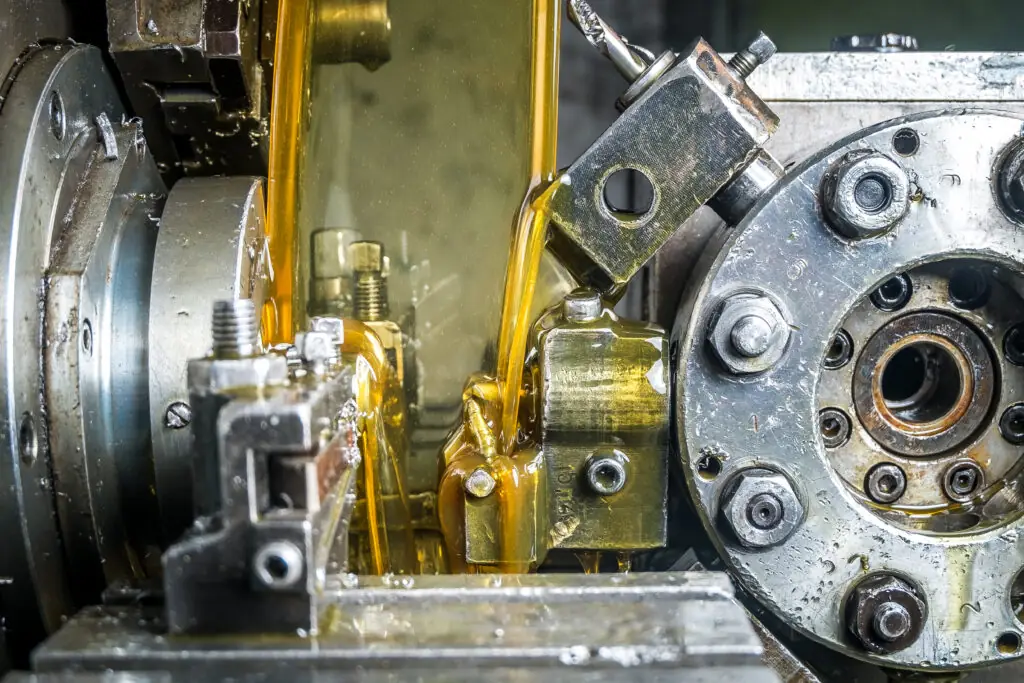

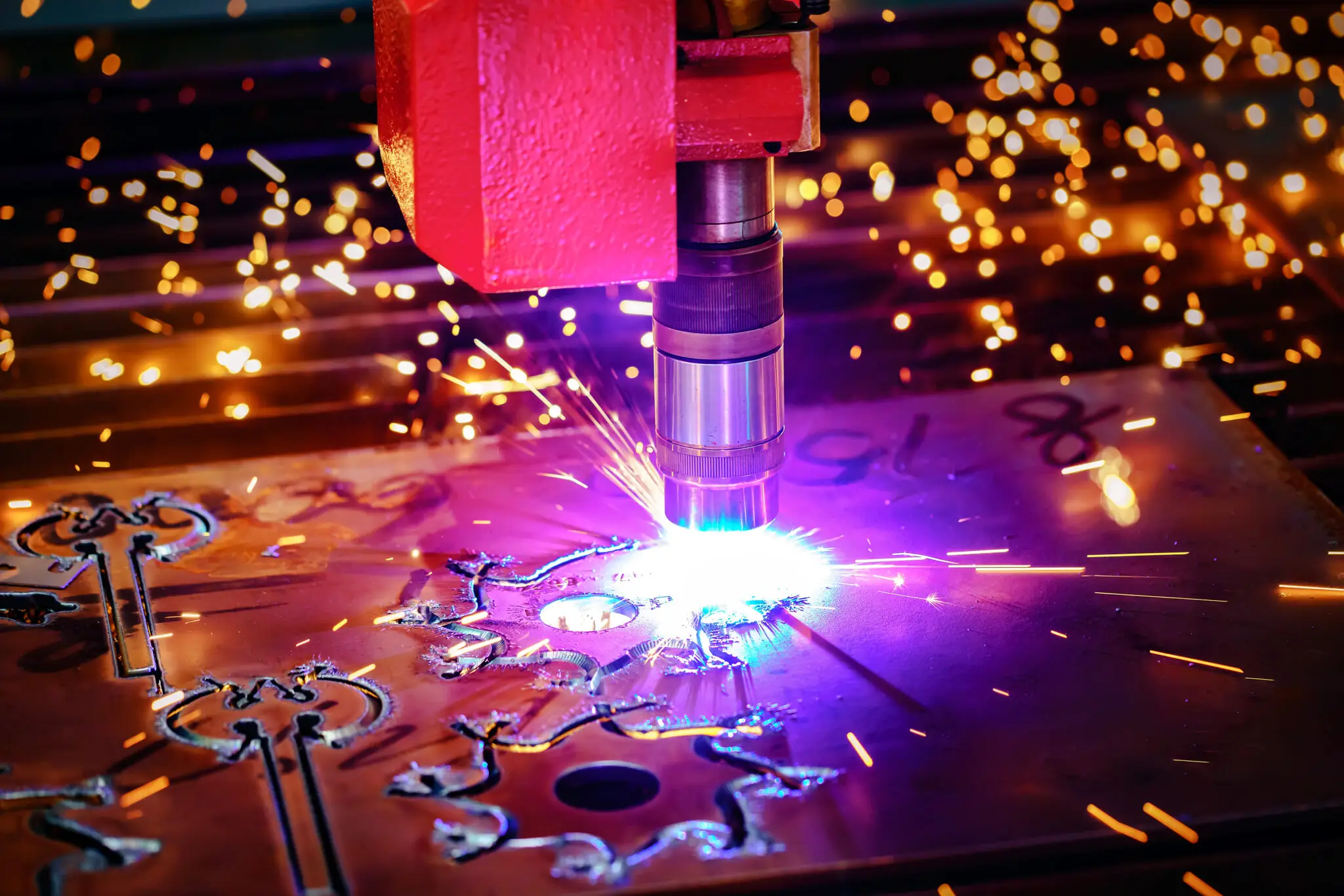

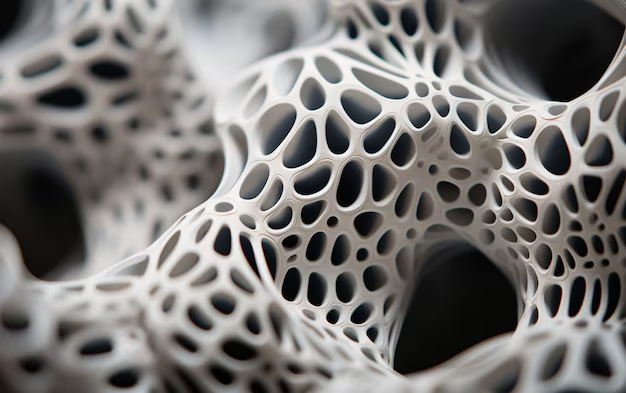

Our services range from prototype design to large-scale production, from CNC lathes to milling centers, injection molding, advanced 3D printing equipment, etc.

400,000 +

Uniquely designed parts produced 400,000 +

15 +

15 + Years in Business

What is rapid prototyping in the context of CNC milling?

Rapid prototyping in CNC milling refers to the process of quickly fabricating a scale model or a functional prototype of a part using CNC milling machines. This method allows for fast iterations and adjustments based on design feedback.

How does CNC milling enhance the rapid prototyping process?

CNC milling enhances rapid prototyping by providing high precision and the ability to work with a variety of materials, which allows for the creation of complex geometries and detailed prototypes that closely resemble the final product.

What materials are commonly used in rapid prototyping with CNC milling?

Common materials used in rapid prototyping with CNC milling include plastics such as acrylic and nylon, metals like aluminum and stainless steel, and composites, depending on the requirements of the prototype.

What are the advantages of using CNC milling for rapid prototyping over traditional methods?

The advantages of using CNC milling for rapid prototyping include faster production times, higher accuracy, the ability to produce complex shapes, and the flexibility to modify designs easily, which makes it a preferred choice for many engineering and design applications.

Want To Know More About Rapid Prototyping Cnc Milling?

TOP Prototype combines expertise in rapid prototyping cnc milling with practical solutions, empowering you to navigate this exciting field.

The Crucial Role of CNC Machined Parts in the Medical Industry by TOP Prototype

The Crucial Role of CNC Machined Parts in the Medical Industry by TOP Prototype The medical industry is constantly evolving, driven by the need for more precise, reliable, and innovative solutions to improve patient care and treatment outcomes. One of the key elements contributing to this progress is the use of CNC machined

Metal Surface Treatment: Processes and Significance

Metal Surface Treatment: Processes and Significance Metal surface treatment is a crucial aspect in the manufacturing and engineering fields. It involves various techniques that modify the surface properties of metals to enhance their performance, durability, and aesthetic appeal. Common Metal Surface Treatment Processes: Anodizing Anodizing is widely used, especially for aluminum. In this process,

The Role of CNC Machined Parts in Electronic Components

The Significance of CNC Machined Parts in Electronic Components In the modern world of technology, electronic components play a crucial role in powering a vast array of devices, from smartphones and laptops to complex industrial machinery. At the heart of the production of these high-tech gadgets lies the precision manufacturing of components, and one

TOP Prototype 2023 Chinese New Year holiday Notice

Notice on the 2024 Spring Festival holiday Greetings, As December approaches, Christmas cheer is in the air! Greetings, As December approaches, Christmas cheer is in the air! All of us at TOP Prototype are excited to send you our warmest holiday wishes. Looking ahead, the New Year and Chinese New Year are just around the

The Excellence of Spraying Surface Treatment

The Excellence of Spraying Surface Treatment Surface treatment is a crucial aspect of modern manufacturing and product enhancement, and spraying is one of the most commonly used and effective methods. This article will delve into the details of spraying, including its definition, working principle, technical knowledge, advantages, and its connection with the TOP Prototype company.

All You Need to Know about SLA Manufacturing in the Medical Industry

In the world of 3D printing, SLA manufacturing holds a special place, especially in industries where extreme precision and fine detail are critical. One specific field is the medical industry, where precise, tailored, and biocompatible components may have a life-changing impact. Among the numerous additive manufacturing methods, SLA manufacturing has become a preferred method for

More About Rapid Prototyping Cnc Milling & Top Prototype

Over the last few years, our factory absorbed and digested advanced technologies, defining our professional approach. We welcome new and previous clients from all walks of lifestyle to get in touch with us for long term business relationships and mutual accomplishment! The world is our market – this rapid prototyping cnc milling will be supplied globally to West Asia, South Africa, Canada, Eastern Europe, etc. Our aim is to help customers realize their goals, we innovate with integrity, putting you first is our mission. You are most welcome to come to China, to our city and our factory! Call or E-mail us your specifications or inquiries right now. TOP Prototype is dedicated into the market to providing premium rapid prototyping cnc milling and service worldwide. We are looking forward to cooperating with you and providing our best services for you, as well as our rapid prototyping cnc milling, Aerospace Manufacturing,SWISS LATHE PROCESSING. Our experienced R&D team is here to provide you with professional support, feel free to tell us your special requests or concerns, each product has been professionally certified to meet industry standards.

Other Categories From Top Prototype

Why Choose Top Prototype Rapid Prototyping Cnc Milling ?

Rapid prototyping through CNC milling is a transformative approach in product design and manufacturing, allowing for the swift production of precise prototypes from digital models. This technique employs advanced computer numerical control (CNC) machinery to carve materials such as metal, plastic, and wood, enabling designers to quickly iterate and refine their concepts. The experiential nature of this process is particularly valuable; it not only accelerates time-to-market but also creates tangible models that can be tested and evaluated in real-world scenarios. By harnessing CNC milling for rapid prototyping, businesses can foster innovation, reduce development costs, and enhance collaboration, ultimately leading to more effective and market-ready products.

Safety Of Rapid Prototyping Cnc Milling

Rapid prototyping through CNC milling is a game-changer in the design and manufacturing process, offering a swift pathway from conceptualization to tangible products. While the precision and efficiency of CNC machines unlock creative potential, safety remains paramount. Operators must be well-versed in machine protocols, wear appropriate protective gear, and maintain a clutter-free workspace to mitigate risks. As we embrace the power of technology to innovate, fostering a culture of safety ensures that creativity flourishes without compromise.

Rapid Prototyping Cnc Milling Design

- Definition: Rapid prototyping CNC milling is a process that quickly fabricates a physical part from a digital model, allowing for fast design iterations.

- Speed: Enables designers to create prototypes in a fraction of the time compared to traditional methods, accelerating the overall development cycle.

- Precision: CNC milling provides high accuracy and detail, ensuring that prototypes closely match the final product specifications.

- Material Variety: Capable of working with a wide range of materials, including plastics, metals, and composites, expanding design possibilities.

- Cost-Effectiveness: Reduces the costs associated with prototyping by minimizing waste and enabling bulk material usage.

- Iterative Design: Facilitates rapid testing and feedback, allowing designers to refine and improve products efficiently.

- Collaboration: Enhances teamwork by providing tangible prototypes that can be easily shared and discussed among stakeholders.

Unique Features From Top Prototype

- Speed: Rapid prototyping enables quick turnaround times, allowing designers to create and test prototypes in days rather than weeks.

- Precision: CNC milling offers high accuracy, ensuring that prototypes are created to exact specifications, which is crucial for functional testing.

- Material Variety: Supports a range of materials, from plastics to metals, providing flexibility to meet diverse project needs.

- Complex Geometries: Capable of producing intricate designs that are often challenging to achieve through traditional manufacturing methods.

- Iterative Development: Facilitates rapid iterations, allowing for continuous improvement based on feedback and testing results.

- Cost-Effective: Reduces costs associated with tooling and setup, making it an attractive option for startups and small-scale projects.

9 thoughts on “Rapid Prototyping Cnc Milling”

This company has a visionary mindset. Their rapid prototyping CNC milling techniques and ideas are sure to propel them ahead in the industry!

This rapid prototyping CNC milling machine is excellent, affordable, and user-friendly—definitely worth a purchase!

Overall, I’m really happy with the rapid prototyping CNC milling and definitely want to leave a positive review!

I’m really impressed with how accurate and consistent this company’s rapid prototyping CNC milling is. They’ve managed to cut their production time by at least half compared to other suppliers, which is super important for us!

Looking forward to working together more with them because their rapid prototyping CNC milling is top-notch!

We’re really excited about the possibility of working together! Your company’s samples for rapid prototyping CNC milling are impressive, and we’re quite pleased with this collaboration. I’m confident that we’ll see great things happen soon!

I just gave it a shot, and the rapid prototyping CNC milling works like a charm—super convenient!

This manufacturer has really enhanced our shopping experience. Their customer service is super attentive, and the quality of the rapid prototyping CNC milling products we received is excellent. Trust me, they truly care about what they do!

My clients were so impressed with these rapid prototyping CNC milling products that I’ve decided to keep coming back for more next time!

Comments are closed.