Prototyping Medical Devices | Strongly Competitive China Factory 2024

Top-quality wholesale prototyping medical devices from top prototype | factory direct sales search top prototype, who provides quality prototyping medical devices. we devote to prototyping medical devices market for several yrs.

Welcome To The Top Prototype Category

Top-quality wholesale prototyping medical devices from top prototype | factory direct sales search top prototype, who provides quality prototyping medical devices. we devote to prototyping medical devices market for several yrs.

Prototyping Medical Devices Boost Your Profit!

Find exceptional Innovative prototyping medical devices options at TOP Prototype. Consider TOP Prototype for the best prototyping medical devices if you’re in the market for prototyping medical devices.

Prototyping Medical Devices: Discover Customer Reviews And Feedback!

We serve a global customer base with our preferred prototyping medical devices.

Interested In Prototyping Medical Devices? Contact Us Now!

We take pride in producing jigh-performance that are of top quality, built to last, and easy to maintain. Discover more on our website.

Faster

When you complete the part design, share it with our company by email and synchronize your requirements.TOP Prototype adopts the most efficient quotation service and focuses on your product requirements.

Leading Capabilities

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

400,000 +

Uniquely designed parts produced 400,000 +

What is prototyping in the context of medical devices?

Prototyping in the context of medical devices refers to the process of creating an early sample or model of a device to test and validate its design, functionality, and usability before full-scale production.

Why is prototyping important for medical device development?

Prototyping is crucial because it allows designers and engineers to identify and rectify design flaws, improve user experience, and ensure compliance with regulatory standards, ultimately leading to safer and more effective medical devices.

What methods are commonly used for prototyping medical devices?

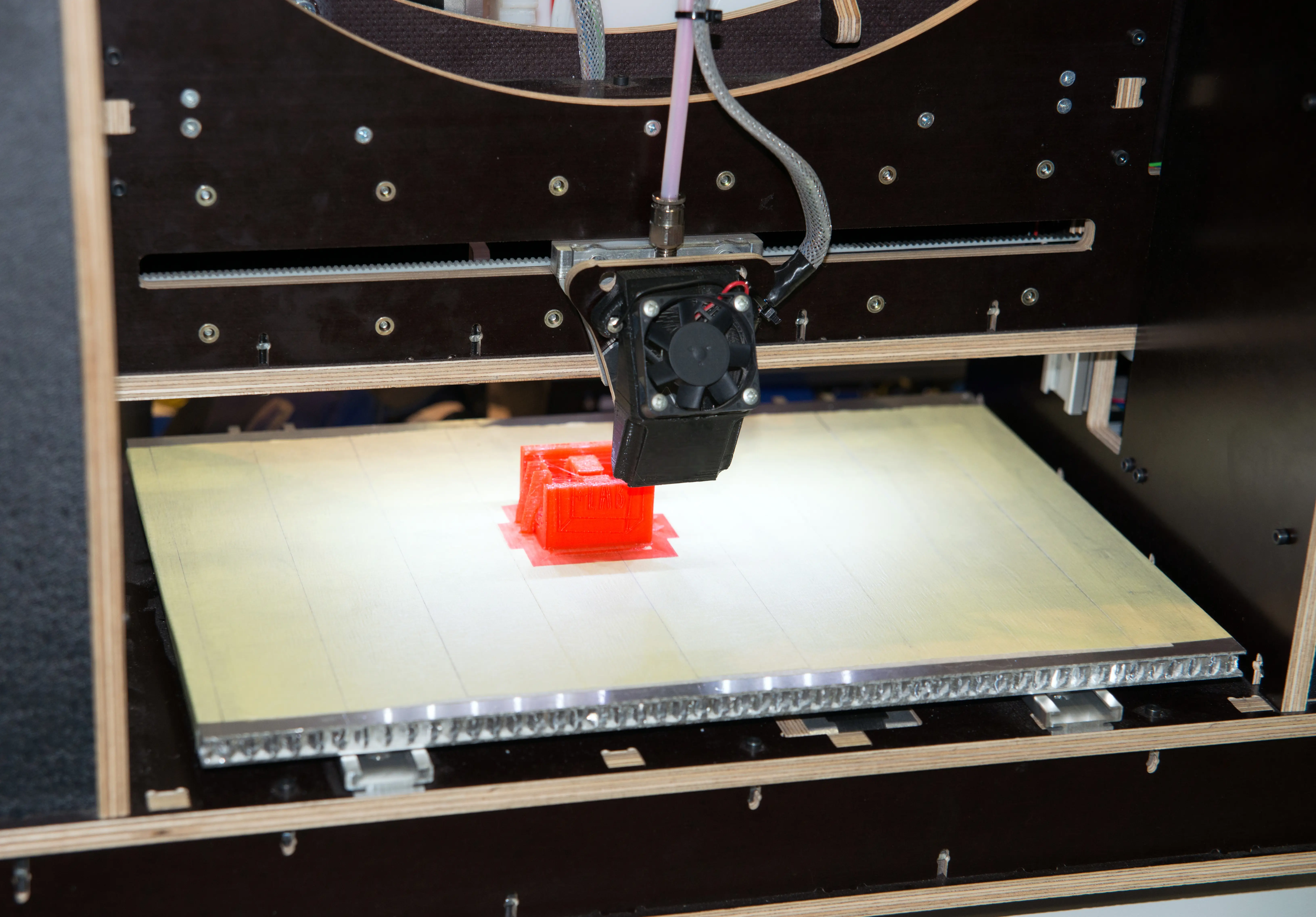

Common methods for prototyping medical devices include 3D printing, computer-aided design (CAD) simulations, and the use of rapid prototyping techniques that allow for quick iterations and modifications.

How does prototyping impact the regulatory approval process for medical devices?

Prototyping impacts the regulatory approval process by providing tangible evidence of the device’s functionality and safety, which is essential for meeting the requirements set by regulatory bodies such as the FDA or EMA during the submission process.

Want To Know More About Prototyping Medical Devices?

TOP Prototype combines expertise in prototyping medical devices with practical solutions, empowering you to navigate this exciting field.

All You Need to Know about SLA Manufacturing in the Medical Industry

In the world of 3D printing, SLA manufacturing holds a special place, especially in industries where extreme precision and fine detail are critical. One specific field is the medical industry, where precise, tailored, and biocompatible components may have a life-changing impact. Among the numerous additive manufacturing methods, SLA manufacturing has become a preferred method for

Key Advantages Propelling the Popularity of Injection Molding

Key Advantages Propelling the Popularity of Injection Molding Exceptional Precision and Dimensional Accuracy Injection molding, as practiced by TOP Prototype, offers an outstanding level of precision that is crucial in many industries. The molds used in the process are fabricated with utmost care and accuracy, often with tolerances in the micrometer range. This

Definition and Significance of TOP Prototype Sheet Metal

Definition and Significance of TOP Prototype Sheet Metal Sheet metal is an essential component in the manufacturing and engineering industries. TOP Prototype, a renowned company in this field, has extensive experience in handling sheet metal. It plays a crucial role in the production of a wide variety of products, ranging from automobiles and aircraft

Notice on the 2024 Spring Festival holiday

Notice on the 2024 Spring Festival holiday Dear customer, As December approaches, Christmas cheer is in the air! Greetings, As December approaches, Christmas cheer is in the air! All of us at TOP Prototype are excited to send you our warmest holiday wishes. Looking ahead, the New Year and Chinese New Year are just around

TOP Prototype 2023 Chinese New Year holiday Notice

Notice on the 2024 Spring Festival holiday Greetings, As December approaches, Christmas cheer is in the air! Greetings, As December approaches, Christmas cheer is in the air! All of us at TOP Prototype are excited to send you our warmest holiday wishes. Looking ahead, the New Year and Chinese New Year are just around the

More About Prototyping Medical Devices & Top Prototype

We keep on with our business spirit of quality, we insist on innovation and integrity, customer first, quality excellent. We are looking forward to cooperating with you and providing our best services for you, as well as our prototyping medical devices, Aerospace Manufacturing,SWISS LATHE PROCESSING. Over the past few years, our factory absorbed and digested integrated advanced technologies, exceeding the industry standard. We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. Our prototyping medical devices will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc. We are looking forward to doing business with you sincerely! Call or E-mail us your specifications or inquiries right now. TOP Prototype is dedicated into the market to providing premium prototyping medical devices and service worldwide. With our cutting-edge production facilities, we assure the production of high-quality goods, we are open to discuss on product improvements and customization is possible we ensure that every product meets the criteria for professional certification.

Other Categories From Top Prototype

Why Choose Top Prototype Prototyping Medical Devices ?

In the fast-paced world of medical innovation, the stakes are incredibly high. Lives are on the line, and every second counts. Prototyping medical devices is not just a technical task; it’s an emotional journey driven by the profound desire to improve patient care and outcomes. Imagine the urgency of bringing a life-saving device from concept to reality, all while navigating the complex landscape of regulations, safety, and efficacy. Each prototype represents hope—a tangible manifestation of dreams that could alleviate suffering and transform lives. In this high-pressure arena, the adrenaline of creativity collides with the weight of responsibility, making rapid prototyping an exhilarating yet daunting endeavor. It’s a race against time, fueled by passion and the relentless pursuit of innovation. Every prototype crafted in these moments is a testament to human ingenuity, embodying the belief that we can and must do better for those in need.

Design Of Prototyping Medical Devices

In the fast-evolving field of medical device development, rapid prototyping has become an essential practice, enabling designers to swiftly translate concepts into tangible products. This approach not only accelerates the innovation cycle but also fosters collaboration among multidisciplinary teams. As the demand for personalized and efficient healthcare solutions rises, the popularity of rapid prototyping continues to grow, allowing for iterative testing and refinement. By embracing this method, designers can ensure that medical devices are not only functional but also user-friendly and tailored to meet the specific needs of patients and healthcare providers alike.

Prototyping Medical Devices Ease Of Construction

- Ease of Construction: Rapid prototyping simplifies the development process, allowing for quick iteration and modification to optimize design.

- Cost-Effective: Reduces materials and labor costs, enabling teams to test multiple concepts without significant financial risk.

- Speed: Accelerates the time from idea to prototype, facilitating faster feedback from stakeholders and end-users.

- Enhanced Collaboration: Fosters cross-disciplinary teamwork, integrating insights from engineers, designers, and healthcare professionals.

- Patient-Centric Design: Allows for user testing and refinement based on real-world feedback, improving usability and effectiveness.

- Regulatory Compliance: Early prototypes can help identify potential regulatory challenges, streamlining the path to market.

- Popularity: Increasingly utilized in med-tech startups and established companies alike, rapidly becoming a standard practice in device development.

Unique Features From Top Prototype

- Unique Features:

- Iterative Design: Rapid prototyping allows for continuous refinement based on user feedback.

- Cost-Effective Solutions: Reduces the financial risk by allowing quick adjustments and validations.

- Enhanced Collaboration: Facilitates teamwork among engineers, designers, and healthcare professionals.

- Realistic Testing: Functional prototypes enable practical assessments in clinical settings.

- Popular Use Cases:

- Wearable Devices: Prototyping accelerates the development of health monitoring technologies.

- Assistive Technologies: Rapid models are key for testing features beneficial for disabled users.

- Surgical Instruments: Quick iterations help ensure precision and usability in the surgical environment.

- Implantable Devices: Allows for thorough testing of biocompatibility and functionality before production.

7 thoughts on “Prototyping Medical Devices”

Your customer service team not only takes our product issues seriously but also provides us with helpful tips on how to use, maintain, and handle prototyping medical devices. That’s really great!

They not only delivered on time, but the quality of the prototyping medical devices was also impressive!

Our shipment is crucial, so we frequently check in on the status. Their managers are always helpful in keeping us updated on the production progress and highlighting any issues. It’s truly a blessing to have that support!

Since time was of the essence, our customer service team quickly coordinated with the factory to expedite production. The express delivery was super speedy too, and in the end, everything arrived right on schedule—perfectly!

I feel super lucky to have snagged such a great deal on prototyping medical devices! The delivery was quick, the packaging was top-notch, and the manufacturer is really friendly and professional.

The product manager is super cool and really knows their stuff! We had a great chat, and in the end, we came to a mutual agreement about prototyping medical devices.

Great working together! I’ll definitely be back in the future, so feel free to purchase with confidence for your prototyping medical devices!

Comments are closed.