Medical Rapid Prototyping | Boosting Profit: 40%

Medical rapid prototyping from top prototype – factory direct sales. top prototype provides quality medical rapid prototyping ,& owns a long experience, providing top medical rapid prototyping.

Your Guide To Top Prototype Categories

Medical rapid prototyping from top prototype – factory direct sales. top prototype provides quality medical rapid prototyping ,& owns a long experience, providing top medical rapid prototyping.

Medical Rapid Prototyping Boost Your Profit!

TOP Prototype brings you an impressive array of Top-notch medical rapid prototyping. Trust TOP Prototype & their medical rapid prototyping when you’re seeking medical rapid prototyping.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

Customer Feedback On Medical Rapid Prototyping: Don’T Miss Out!

We cater to a diverse international customer base with our unique medical rapid prototyping.

Interested In Medical Rapid Prototyping? Contact Us Now!

We take pride in producing excellent that are of top quality, built to last, and easy to maintain. Discover more on our website.

400,000 +

Uniquely designed parts produced 400,000 +

60 +

60 + Countries Countries shipped

15 +

15 + Years in Business

What is medical rapid prototyping?

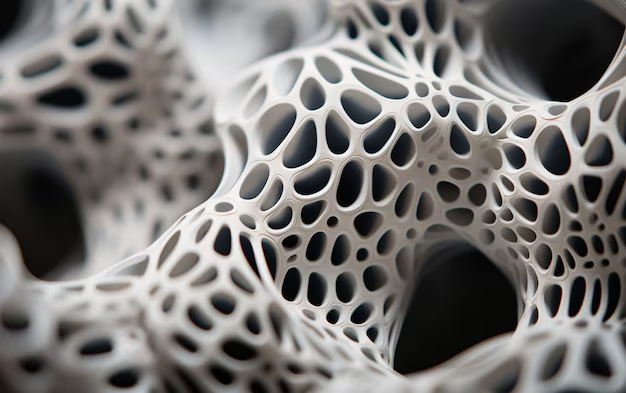

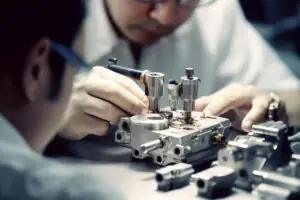

Medical rapid prototyping is a process that uses advanced technologies, such as 3D printing, to quickly create physical models of medical devices or anatomical structures for testing, evaluation, and design purposes.

How does medical rapid prototyping benefit the healthcare industry?

It allows for faster innovation, improved design accuracy, and the ability to customize medical devices or surgical tools to better fit individual patient needs, ultimately enhancing patient care.

What technologies are commonly used in medical rapid prototyping?

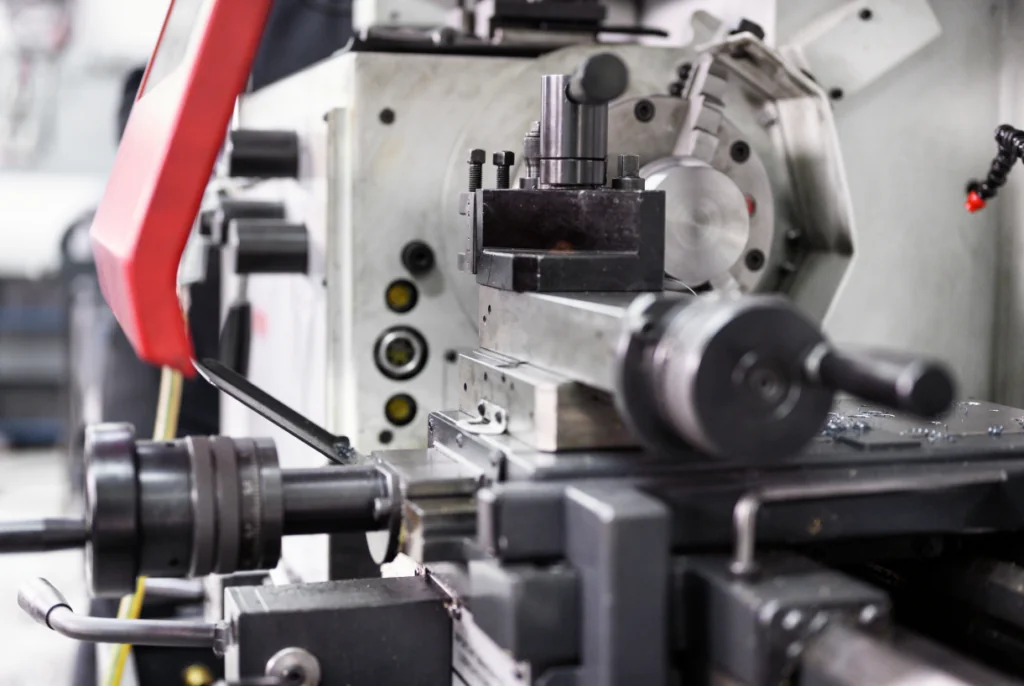

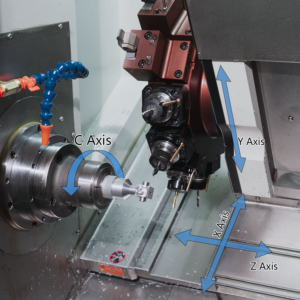

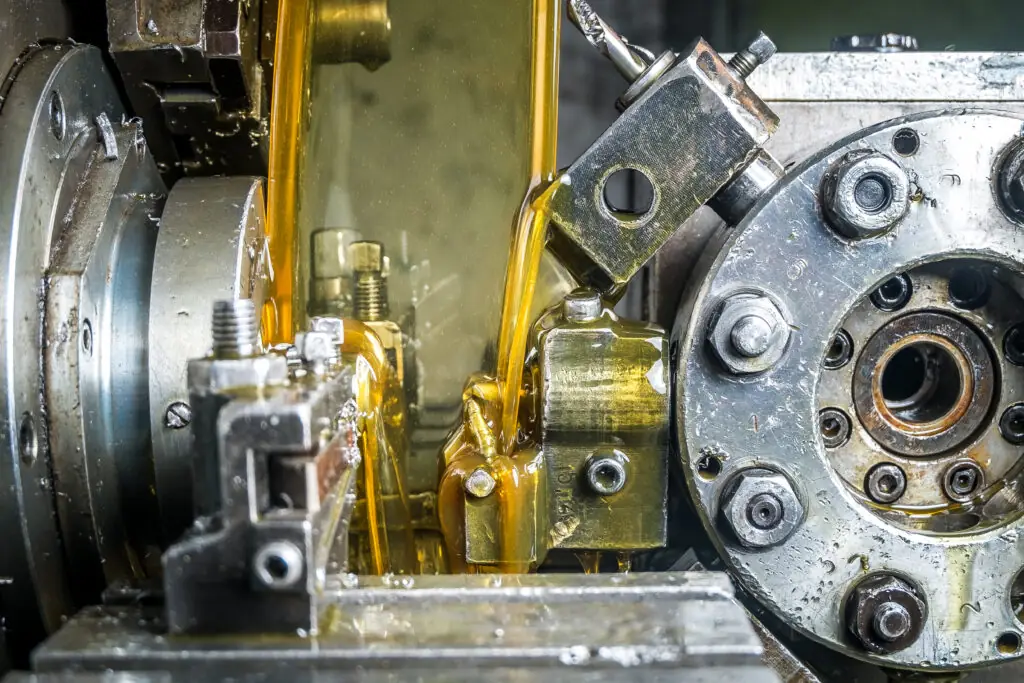

Common technologies include 3D printing (additive manufacturing), CNC machining, and laser cutting, which can create detailed models from various materials.

Can medical rapid prototyping be used for patient-specific applications?

Yes, medical rapid prototyping can create patient-specific models for surgical planning, allowing surgeons to practice procedures on replicas that closely mimic the patient’s anatomy before actual surgery.

Want To Know More About Medical Rapid Prototyping?

Discover how TOP Prototype’s commitment to excellence enriches the landscape of medical rapid prototyping for all enthusiasts.

CNC Machining Tolerance: Significance & Standard & Dependence

CNC prototype machining is all about precision. It produces parts with relative quality and relative dimensional accuracy. Relative to the process, one of the more integral components of it is CNC machining tolerances. It is the acceptable measurement of deviation in the dimension of a part. These tolerances indicate how exact a part is within

Step into the World of TOP Prototype CNC Machined Delights: A Visual Feast

Step into the World of TOP Prototype CNC Machined Delights: A Visual Feast CNC machining has emerged as a revolutionary force, creating a world of precision-engineered wonders that tantalize the eyes and captivate the imagination. TOP Prototype, a renowned name in the industry, has been a key player in this exciting landscape. TOP Prototype’s

3 Key Benefits of Sheet Metal Fabrication

3 Key Benefits of Sheet Metal Fabrication Sheet metal fabrication offers three significant benefits: cost-effectiveness, durability, and versatility. These advantages make it an ideal choice for a wide range of projects. The process becomes more cost-effective as production volume increases, reducing per-unit costs. This affordability, combined with the material’s inherent strength and resistance to environmental

Sheet Metal Processing Materials: Characteristics, Applications, and Innovations

Sheet Metal Processing Materials: Characteristics, Applications, and Innovations Sheet metal processing is a vital part of modern manufacturing, and the choice of materials plays a decisive role in the quality and performance of the final products. TOP Prototype, a distinguished company in this domain, has in – depth knowledge and extensive experience in handling

Sheet Metal Cutting Processes: An In – depth Analysis

Sheet Metal Cutting Processes: An In – depth Analysis

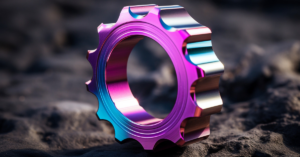

Understanding Anodizing with TOP Prototype: Process, Applications and Challenges

Understanding Anodizing with TOP Prototype: Process, Applications and Challenges I. Introduction What Is Anodizing? Anodizing represents an electrochemical process that transforms the metal surface into a decorative, durable, and corrosion – resistant anodic oxide finish. Among nonferrous metals, while magnesium and titanium can also undergo anodizing, aluminum is the most suitable for this

More About Medical Rapid Prototyping & Top Prototype

TOP Prototype has already had a lot of top factories and qualified technology teams in China, offering the best medical rapid prototyping and services to worldwide customers. With our cutting-edge production facilities, we assure the production of high-quality goods, we are open to discuss on product improvements and customization is possible we ensure that every product meets the criteria for professional certification. We are looking forward to cooperating with you and providing our best services for you, as well as our medical rapid prototyping, Aerospace Manufacturing,SWISS LATHE PROCESSING. Good quality is factory’ existence, providing best products for our customers is our work, focus on customer’ demand is the source of company survival. We’ll satisfy you with our qualified service! If you are interested in any of our products, please feel free to contact us. We are eager to cooperate with foreign companies which care much on the high quality solutions, budget-friendly prices, organizational reputation. Our medical rapid prototyping will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc. Over the last few years, our factory absorbed and digested advanced technologies, defining our professional approach.

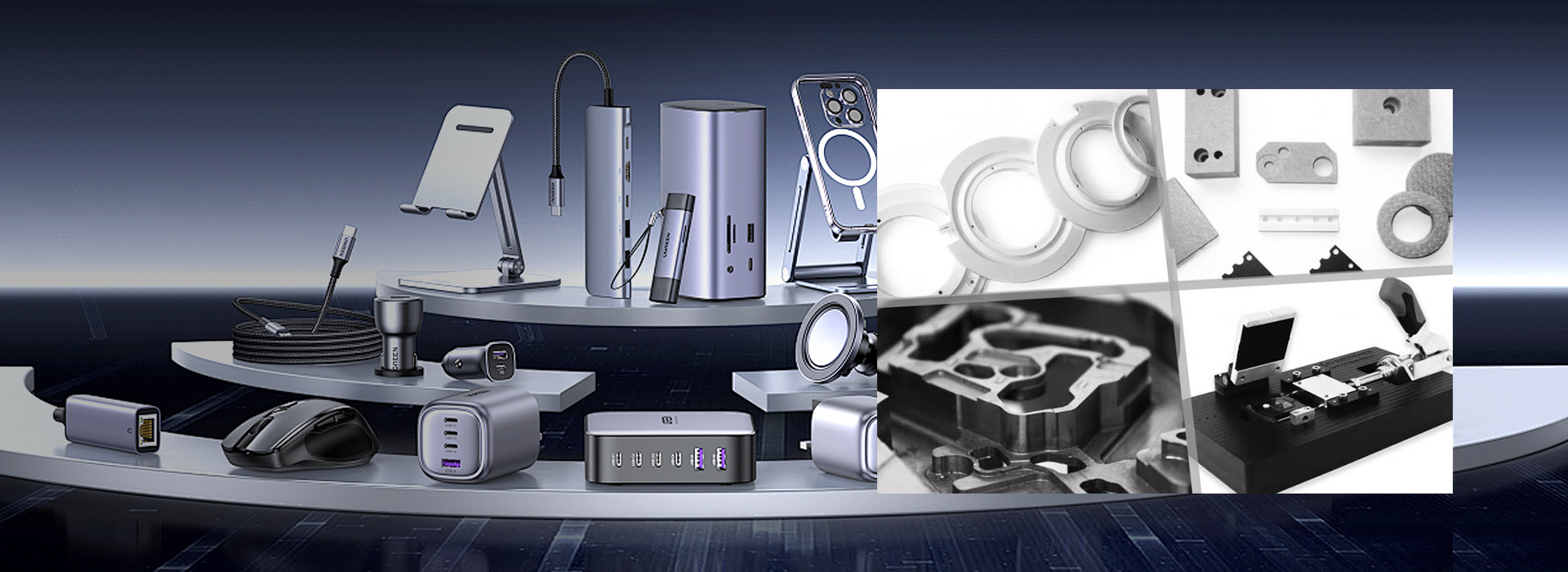

Other Categories From Top Prototype

Why Choose Top Prototype Medical Rapid Prototyping ?

Medical rapid prototyping is a transformative approach that leverages advanced technologies to create physical models and devices quickly and efficiently, enhancing the design and development processes in healthcare. By utilizing techniques such as 3D printing and computer-aided design (CAD), medical professionals and researchers can produce intricate anatomical models, surgical guides, and customized implants tailored to patient-specific needs. This innovation not only accelerates the prototyping phase but also fosters collaboration across international borders, enabling researchers and clinicians to share insights and best practices. As the global landscape of healthcare continues to evolve, medical rapid prototyping stands at the forefront, driving advancements that improve patient outcomes and streamline medical procedures.

Durability Of Medical Rapid Prototyping

Medical rapid prototyping has emerged as a transformative approach in healthcare, significantly enhancing the development of durable medical devices and personalized implants. By utilizing advanced materials and innovative techniques, prototypes can be created with regional specifications that cater to the unique anatomical and physiological needs of diverse patient populations. This regional tempering ensures that every prototype not only meets rigorous health standards but also offers the resilience required for real-world applications, ultimately improving patient outcomes and expediting the delivery of critical healthcare solutions.

Medical Rapid Prototyping Energy Efficiency

- Innovative Solutions: Medical rapid prototyping enables the swift development of customized medical devices and implants to meet specific patient needs.

- Energy Efficiency: Utilizes advanced technologies to reduce material waste and energy consumption during the prototyping process.

- Regional Adaptability: Tailors solutions to meet local regulatory standards and healthcare challenges, promoting regional healthcare innovation.

- Enhanced Collaboration: Facilitates teamwork among medical professionals, engineers, and designers, fostering a multidisciplinary approach to healthcare solutions.

- Improved Patient Outcomes: Accelerates the prototyping phase, leading to faster implementation of effective treatments and improved healthcare delivery.

Cost-Effectiveness From Top Prototype

- Cost-effectiveness: Rapid prototyping reduces the time and resources required to develop medical devices, leading to significant cost savings.

- Regional Temper: The effectiveness of rapid prototyping can vary by region, influenced by local regulations, technological access, and market needs.

- Iterative Development: Facilitates quick iterations and modifications, allowing for improved design based on real-world feedback.

- Custom Solutions: Enables tailored medical solutions that cater to specific patient demographics or regional health issues.

- Acceleration of Innovation: Speeds up the time from concept to market, fostering innovation in the medical field.

5 thoughts on “Medical Rapid Prototyping”

This collaboration has exceeded my expectations, and the medical rapid prototyping products are fantastic! What this company offers is top-notch and affordable!

As the market grows and production scales up, along with the demands of market development and our company’s push for technological innovation, we’ve been focusing on medical rapid prototyping.

The customer service team is super friendly, the medical rapid prototyping arrived in no time, and overall, it was a fantastic shopping experience!

The medical rapid prototyping product looks great, is easy to use, and listening to the customer service introduction feels really straightforward.

We love how your medical rapid prototyping solutions are both chic and simple, and it’s great to see that your designers value our input!

Comments are closed.