Injection Molding Solutions | More Profit, Less Effort – 35% More!

Top-quality wholesale injection molding solutions from top prototype | free samples top prototype provides quality injection molding solutions ,& owns a long experience, providing top injection molding solutions.

Welcome To The Top Prototype Category

Top-quality wholesale injection molding solutions from top prototype | free samples top prototype provides quality injection molding solutions ,& owns a long experience, providing top injection molding solutions.

Injection Molding Solutions By Top Prototype: Delivering Excellence!

Choose from a wide range of Premium injection molding solutions at TOP Prototype. If injection molding solutions are your priority, TOP Prototype offers reliable injection molding solutions to explore.

Injection Molding Solutions: Discover Customer Reviews And Feedback!

We extend our highly recommended injection molding solutions to customers from all corners of the globe.

Curious About Top Prototype’S Offerings In Injection Molding Solutions? Don’T Hesitate To Reach Out!

We craft our highly recommended with excellence, ensuring durability and minimal upkeep. Visit our website to learn more.

Faster

When you complete the part design, share it with our company by email and synchronize your requirements.TOP Prototype adopts the most efficient quotation service and focuses on your product requirements.

Leading Capabilities

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

24/7 Engineering Support

24/7 Engineering Support

TOP Prototype has a team of experienced engineers to provide auxiliary advice for your project, helping you optimize your design, save costs, and achieve better and more consistent quality standards through standardization.

What is injection molding solutions?

Injection molding solutions refer to the processes and technologies used to create parts by injecting molten materials, typically plastics, into a mold. This method allows for high-volume production of complex shapes with precision and consistency.

What are the advantages of using injection molding solutions?

The advantages include high production efficiency, the ability to produce intricate designs, reduced waste, and consistent quality across large batches of products. Additionally, it allows for easy automation and scalability.

What materials can be used in injection molding solutions?

Various materials can be used in injection molding, including thermoplastics like ABS, polycarbonate, and polypropylene, as well as thermosetting plastics and certain metals. The choice of material depends on the desired properties of the final product.

How do I choose the right injection molding solution for my project?

Choosing the right injection molding solution involves considering factors like the type of material, the complexity of the design, production volume, cost constraints, and specific performance requirements of the final product. Consulting with an experienced injection molding provider can help in making the best decision.

Want To Know More About Injection Molding Solutions?

TOP Prototype combines expertise in injection molding solutions with practical solutions, empowering you to navigate this exciting field.

What is CNC machining? The complete basics of getting started

Wondering about CNC machining and why it’s so important in manufacturing? You’re not alone. Computer numerical control (CNC) machining is a key role in modern manufacturing, utilizing advanced technology to cut, shape and manufacture precision parts. This article details the working principle of CNC machine tools and their role in manufacturing a variety of products,

Everything You Need to Know about Multi-Axis Machining

CNC machining has come a long way over the years, from basic 2D cutting to advanced multi-axis machining that handles complex shapes with high precision and speed. As product designs get more advanced, multi-axis machining plays a key role in meeting modern manufacturing needs. That said, in this blog, we’ll explain the basics, main components,

7 Reasons for Embracing CNC Rapid Prototyping

Computer Numerical Control (CNC) rapid prototyping refers to the use of CNC machining technology to create prototypes quickly and accurately from a digital design. The process involves converting 3D models into machine code, which then directs CNC equipment to cut or shape materials into physical prototypes. CNC rapid prototyping has become a vital part of

The Excellence of Spraying Surface Treatment

The Excellence of Spraying Surface Treatment Surface treatment is a crucial aspect of modern manufacturing and product enhancement, and spraying is one of the most commonly used and effective methods. This article will delve into the details of spraying, including its definition, working principle, technical knowledge, advantages, and its connection with the TOP Prototype company.

Case study :TOP Prototype and Tesla’s extraordinary wheel kit

Case study :TOP Prototype and Tesla’s extraordinary wheel kit Wondering about CNC machining and why it’s so important in manufacturing? You’re not alone. Computer numerical control (CNC) machining is a key role in modern manufacturing, utilizing advanced technology to cut, shape and manufacture precision parts. This article details the working principle of CNC machine tools

Comprehensive guide for sheet metal edging: Techniques, uses and techniques

Sheet metal is widely used in the automotive and electronics industries. Over time, however, its sharp edges can become deformed and pose a safety risk. To solve this problem, the edges are often folded in a process called sheet metal flanging. This article explains what edging is, how it is done, the types of edging

More About Injection Molding Solutions & Top Prototype

Your request is our command! You can contact us, and we will provide you a quotation up on receipt of the detailed needs. We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. The world is our market – this injection molding solutions will be supplied globally to West Asia, South Africa, Canada, Eastern Europe, etc. Our production process upholds the highest standards, we accept and consider all orders with unique specifications, each product has been professionally certified to meet industry standards. Over the last few years, our factory absorbed and digested advanced technologies, defining our professional approach. Owning a factory and top-notch technologies, TOP Prototype always offers unmatchable injection molding solutions worldwide. We are looking forward to cooperating with you and providing our best services for you, as well as our injection molding solutions, Aerospace Manufacturing,SWISS LATHE PROCESSING. We hunt forward towards your coming, dedication to high-quality is our life, customer first’ is our motto.

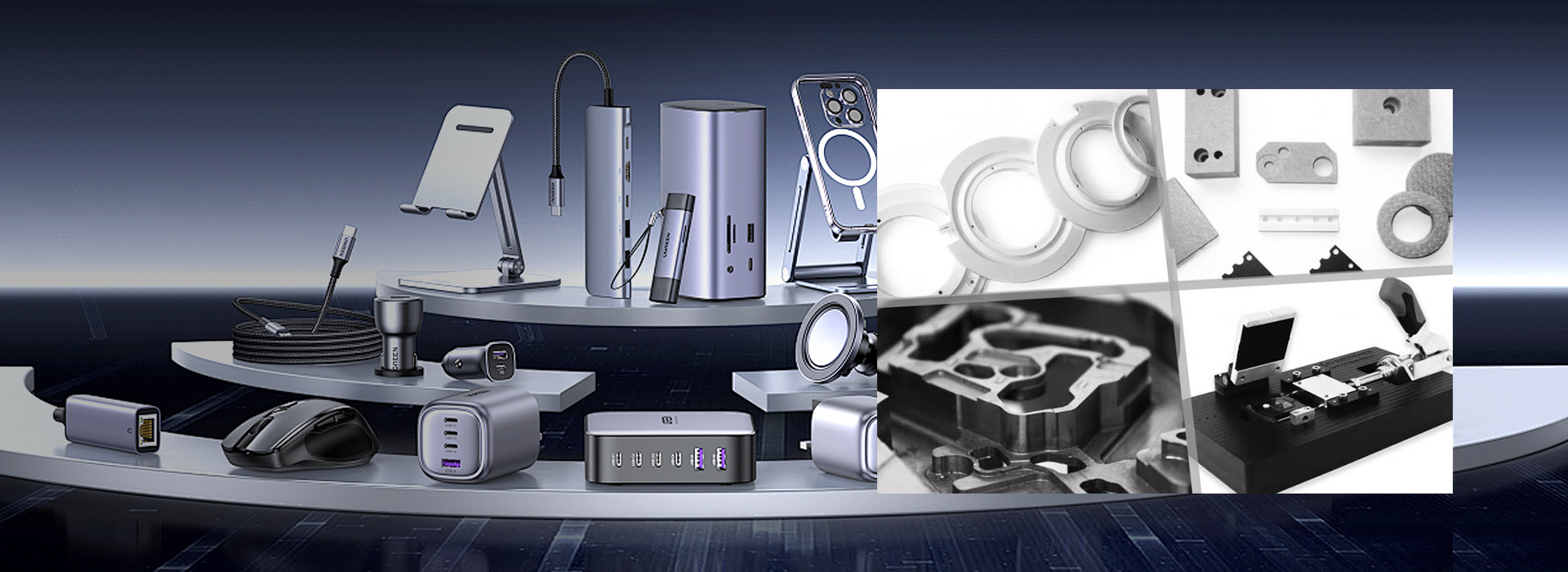

Other Categories From Top Prototype

Why Choose Top Prototype Injection Molding Solutions ?

Injection molding is a revolutionary manufacturing process that allows for the rapid and efficient production of intricate parts from a variety of materials, primarily thermoplastics and thermosets. This technique involves injecting molten material into a precisely designed mold, where it cools and solidifies to form the desired shape. The interdisciplinary nature of injection molding solutions integrates knowledge from various fields such as engineering, materials science, and design, enabling the development of innovative products tailored to specific industry needs. As a cornerstone of modern manufacturing, injection molding not only enhances production speed and accuracy but also supports sustainability efforts by minimizing material waste and allowing for recycling of plastics. By leveraging advanced technologies and collaborative approaches, businesses can harness the full potential of injection molding solutions to stay competitive in today’s rapidly evolving market.

Precision Of Injection Molding Solutions

Injection molding is a leading manufacturing process celebrated for its precision and efficiency in producing complex parts. With the ability to create intricate geometries, this technique excels in maintaining tight tolerances and uniformity across large production runs. The direct relationship between temperature and material flow ensures optimal filling of molds, minimizing defects and enhancing overall part integrity. As a rapid prototyping solution, injection molding not only accelerates product development but also enables cost-effective scaling for high-volume production.

Injection Molding Solutions Reliability

- Reliability: Injection molding delivers consistent quality, ensuring high precision and minimal defects in mass production.

- Durability: Parts produced are robust and can withstand various environmental conditions, enhancing product lifespan.

- Direct Temperature Control: Advanced temperature regulation during the injection process ensures optimal material flow and part integrity.

- Cost-Effective: Ideal for large production runs, reducing per-unit costs significantly compared to other manufacturing methods.

- Versatility: Compatible with a wide range of materials, allowing for the production of diverse components tailored to specific needs.

- Fast Cycle Times: Quick production rates enhance efficiency and accelerate time-to-market for new products.

Durability From Top Prototype

- Durability: Injection molding produces highly durable parts that withstand extreme conditions and stress, ensuring longevity and reliability.

- Temperature Resistance: Parts can be engineered to endure high and low temperatures, making them suitable for diverse applications.

- Precision: This method enables direct, high-precision manufacturing, ensuring consistent quality and dimensional accuracy.

- Material Versatility: A wide range of materials can be used, including thermoplastics and thermosets, allowing for tailored solutions.

- Efficiency: Rapid production cycles decrease lead times, promoting quicker market entry and response to demand.

5 thoughts on “Injection Molding Solutions”

After collaborating, I’ve realized that this company has great potential for improvement, and their injection molding solutions fit our needs perfectly. I really trust them!

Their delivery is quick, the customer service team is fantastic, and they’re super patient with their answers when it comes to injection molding solutions.

You shipped the injection molding solutions super fast, just a few days after we signed the contract, which really shows that you’re a dependable company!

Their customers are pretty happy with the injection molding solutions, and communication flows effortlessly.

The injection molding solutions are really smart, and all the modes function perfectly. I’m relieved that my biggest concern turned out to be a non-issue. I’m quite happy with this reputable product and would definitely recommend it!

Comments are closed.