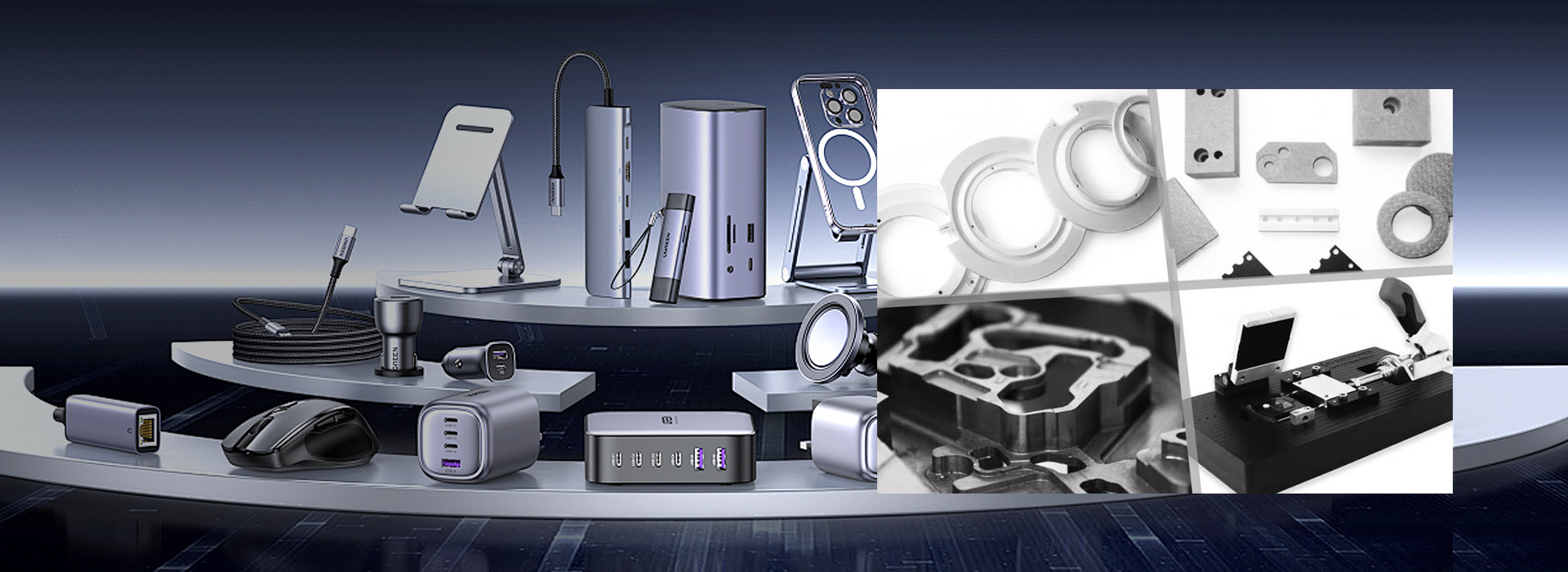

Industrial Rapid Prototyping | Well-Known China Supplier 2024

#1 wholesale industrial rapid prototyping from top prototype | factory direct sales top prototype, offering quality industrial rapid prototyping with plenty yrs experience. the best industrial rapid prototyping!

Welcome To The Top Prototype Category

#1 wholesale industrial rapid prototyping from top prototype | factory direct sales top prototype, offering quality industrial rapid prototyping with plenty yrs experience. the best industrial rapid prototyping!

Industrial Rapid Prototyping – Invest In Quality With Top Prototype!

TOP Prototype brings you an impressive array of Premium industrial rapid prototyping. TOP Prototype is a well-regarded partner with industrial rapid prototyping. You can rely on them for industrial rapid prototyping.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

Customer Review About Industrial Rapid Prototyping: View Custom Reviews Now!

Customers hailing from various countries benefit from our unparralleled industrial rapid prototyping.

Looking For More Information On Industrial Rapid Prototyping? We’Re Here To Help!

We take pride in producing top-quality that are of top quality, built to last, and easy to maintain. Discover more on our website.

Leading Capabilities

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

Variety

Our services range from prototype design to large-scale production, from CNC lathes to milling centers, injection molding, advanced 3D printing equipment, etc.

15 +

15 + Years in Business

What is industrial rapid prototyping?

Industrial rapid prototyping is a process that allows for the quick fabrication of a physical part or assembly using 3D computer-aided design (CAD) data. It enables designers and engineers to create prototypes rapidly, often using techniques such as 3D printing, CNC machining, or injection molding.

What are the benefits of industrial rapid prototyping?

The benefits of industrial rapid prototyping include reduced time to market, cost savings, improved design accuracy, and the ability to test and iterate designs quickly before full-scale production. This allows for faster feedback and adjustments based on real-world testing.

Which industries commonly use industrial rapid prototyping?

Industries that commonly use industrial rapid prototyping include automotive, aerospace, consumer products, healthcare, and electronics. These sectors leverage rapid prototyping to innovate and refine their products efficiently.

What technologies are used in industrial rapid prototyping?

Technologies used in industrial rapid prototyping include additive manufacturing (such as 3D printing), subtractive manufacturing (like CNC machining), and various casting and molding techniques. Each technology offers different advantages depending on material requirements and desired accuracy.

Curious About Industrial Rapid Prototyping? Check What Top Prototype Has To Offer!

With a focus on industrial rapid prototyping, TOP Prototype offers comprehensive resources to deepen your understanding and application.

All You Need to Know about SLA Manufacturing in the Medical Industry

In the world of 3D printing, SLA manufacturing holds a special place, especially in industries where extreme precision and fine detail are critical. One specific field is the medical industry, where precise, tailored, and biocompatible components may have a life-changing impact. Among the numerous additive manufacturing methods, SLA manufacturing has become a preferred method for

CNC Machining of Engineering Plastics by TOP Prototype

CNC Machining of Engineering Plastics by TOP Prototype TOP Prototype is a leading company in the field of precision manufacturing, and we specialize in the CNC machining of various engineering plastics. Our expertise and advanced equipment allow us to deliver high-quality plastic components with exceptional accuracy and efficiency. Let’s explore some common engineering plastics and

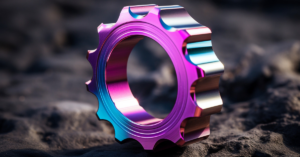

Understanding Anodizing with TOP Prototype: Process, Applications and Challenges

Understanding Anodizing with TOP Prototype: Process, Applications and Challenges I. Introduction What Is Anodizing? Anodizing represents an electrochemical process that transforms the metal surface into a decorative, durable, and corrosion – resistant anodic oxide finish. Among nonferrous metals, while magnesium and titanium can also undergo anodizing, aluminum is the most suitable for this

Comprehensive guide for sheet metal edging: Techniques, uses and techniques

Sheet metal is widely used in the automotive and electronics industries. Over time, however, its sharp edges can become deformed and pose a safety risk. To solve this problem, the edges are often folded in a process called sheet metal flanging. This article explains what edging is, how it is done, the types of edging

High – Precision Sheet Metal Bending in TOP Prototype Company

High – Precision Sheet Metal Bending in TOP Prototype Company Ⅰ. Introduction In the modern manufacturing industry, sheet metal bending plays a crucial role in the production process. TOP Prototype, as a well – known company in this field, has extensive experience and advanced techniques in sheet metal bending operations. This paper will explore the

The Excellence of Spraying Surface Treatment

The Excellence of Spraying Surface Treatment Surface treatment is a crucial aspect of modern manufacturing and product enhancement, and spraying is one of the most commonly used and effective methods. This article will delve into the details of spraying, including its definition, working principle, technical knowledge, advantages, and its connection with the TOP Prototype company.

More About Industrial Rapid Prototyping & Top Prototype

Owning a factory and top-notch technologies, TOP Prototype always offers unmatchable industrial rapid prototyping worldwide. We are eager to cooperate with foreign companies which care much on the high quality solutions, budget-friendly prices, organizational reputation. Our industrial rapid prototyping will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc. With our cutting-edge production facilities, we assure the production of high-quality goods, we are open to discuss on product improvements and customization is possible we ensure that every product meets the criteria for professional certification. We are looking forward to cooperating with you and providing our best services for you, as well as our industrial rapid prototyping, 3D PRINTING,5-AXIS CNC MACHINING. In recent years, our organization encourages creative thinking and cutting-edge technologies, exceeding the industry standard. We upholds the philosophy of being No. 1 in high quality, we insist on innovation and integrity, we adhere to honesty and superior faith working attitude. Customer satisfaction is our main goal. Do contact us at any time you feel free.

Other Categories From Top Prototype

Why Choose Top Prototype Industrial Rapid Prototyping ?

In the fast-paced world of industrial design, rapid prototyping has emerged as a game-changing technology, infusing creativity and efficiency into product development. This innovative process allows designers and engineers to swiftly transform ideas into tangible models, enabling them to visualize concepts, test functionalities, and make critical adjustments on the fly. Gone are the days of lengthy production timelines; with rapid prototyping, the design iteration process accelerates dramatically, fostering an environment where imagination can flourish and ideas can be refined in real-time. Whether through 3D printing, CNC machining, or other advanced techniques, rapid prototyping empowers industries to push boundaries, reduce costs, and bring their visions to life like never before. It’s not just about creating prototypes—it’s about unleashing potential and igniting the sparks of innovation in a competitive landscape.

Energy Efficiency Of Industrial Rapid Prototyping

Industrial rapid prototyping has emerged as a pivotal innovation in energy-efficient manufacturing processes globally. By enabling the swift transformation of ideas into tangible products, this approach significantly reduces material waste and shortens production cycles. The integration of advanced materials and technologies not only accelerates design iterations but also enhances the overall energy efficiency of the production line. As industries worldwide adopt these methodologies, the emphasis on sustainability and international collaboration fosters a new era of environmentally conscious manufacturing. This aligns perfectly with global energy conservation goals, making rapid prototyping not just a method, but a movement towards a more sustainable industrial future.

Industrial Rapid Prototyping Unique Features

- Speed: Rapid prototyping significantly reduces product development time, allowing for quick iterations and faster market entry.

- Cost-Effective: Minimizes expenses associated with traditional manufacturing by limiting material waste and reducing labor costs.

- Design Flexibility: Enables complex geometries and custom designs that are often impossible to achieve with standard manufacturing techniques.

- International Collaboration: Facilitates global team projects through digital designs and 3D printing, overcoming geographical barriers.

- User Feedback: Encourages early user involvement, allowing for adjustments based on real-world testing and feedback.

- Material Variety: Utilizes a wide range of materials, from plastics to metals, offering diverse applications across industries.

- Sustainability: Promotes eco-friendly practices by reducing waste and enabling the use of recyclable materials.

- Technological Integration: Incorporates advanced technologies such as CAD software and 3D printing, enhancing design precision and functionality.

Precision From Top Prototype

- Precision: Rapid prototyping delivers high accuracy in the design process, allowing for intricate details and complex geometries.

- Speed: Significantly reduces the time from concept to physical model, enabling faster iteration and quicker market entry.

- Versatility: Accommodates various materials (plastics, metals, ceramics) to suit diverse industrial applications.

- Cost-Effectiveness: Minimizes production costs by identifying design flaws early, reducing waste and resource expenditure.

- International Standards: Aligns with global manufacturing guidelines, ensuring compatibility and quality across international markets.

- Collaboration: Enhances communication among teams and stakeholders through tangible models, fostering innovation and feedback.

5 thoughts on “Industrial Rapid Prototyping”

They’ve successfully blended technology and production into the everyday details, turning industrial rapid prototyping into a stunning sight. Awesome!

When I first spotted such a low price, I thought the quality might be just okay. However, to my surprise, the company’s industrial rapid prototyping products exceeded my expectations with their great color, texture, and practicality!

Their customer support and installation team are top-notch!

You’re super efficient and always bring a positive vibe—what’s not to love about that, especially when it comes to industrial rapid prototyping?

Throughout this collaboration, we brainstormed a ton of fantastic ideas that hadn’t crossed our minds before. It’s clear to see just how amazing the industrial rapid prototyping solutions we’ve created together turned out!

Comments are closed.