Electronic Prototype Manufacturing | Passionate China Manufacturer 2024

Best wholesale electronic prototype manufacturing from top prototype | factory direct sales top prototype, offering quality electronic prototype manufacturing with plenty yrs experience. the best electronic prototype manufacturing!

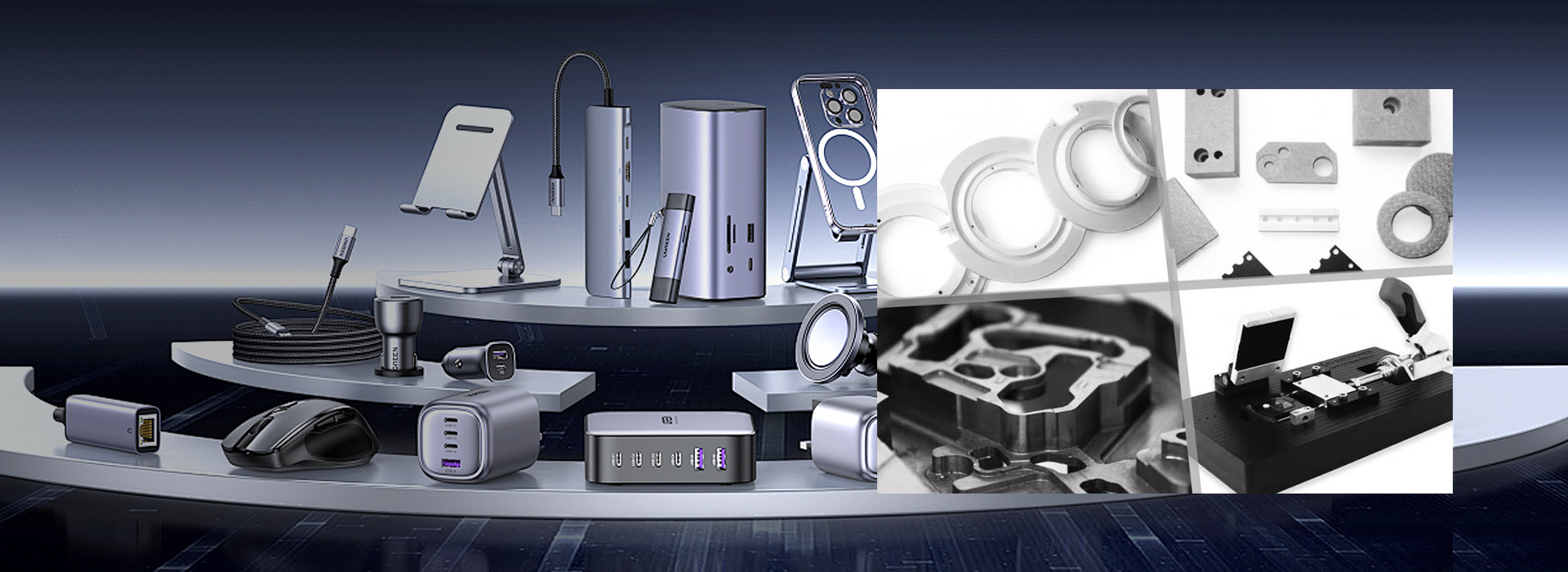

Explore Our Top Prototype Offerings

Best wholesale electronic prototype manufacturing from top prototype | factory direct sales top prototype, offering quality electronic prototype manufacturing with plenty yrs experience. the best electronic prototype manufacturing!

Electronic Prototype Manufacturing – Invest In Quality With Top Prototype!

Don’t miss out on TOP Prototype’s exclusive High-quality electronic prototype manufacturing. When electronic prototype manufacturing are essential, turn to TOP Prototype & top electronic prototype manufacturing.

See What People Are Saying About Electronic Prototype Manufacturing: Read Reviews!

We have the best electronic prototype manufacturing to customers from all over the world.

Curious About Electronic Prototype Manufacturing? Don’T Hesitate To Reach Out!

We craft our preferred with excellence, ensuring durability and minimal upkeep. Visit our website to learn more.

More Responsive Quotes

We will give you feedback within 1 hour to ensure that you receive professional processing suggestions, lower processing costs and a faster delivery time.

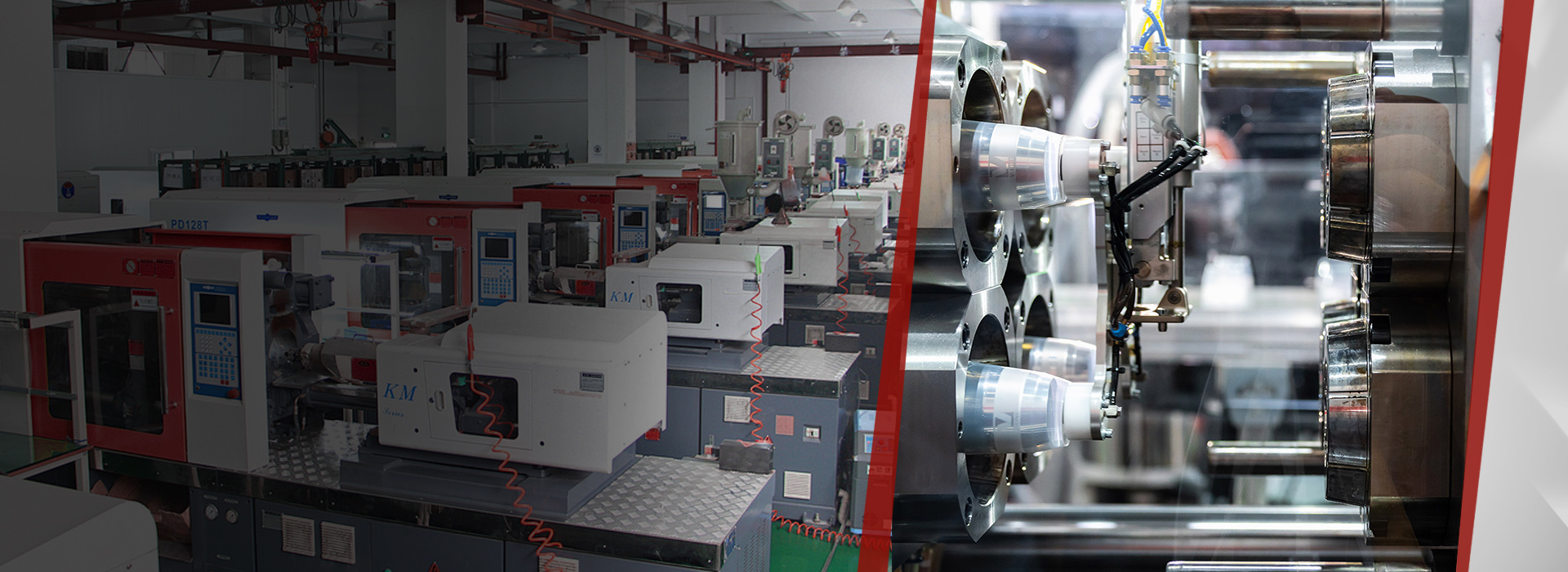

Leading Capabilities

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

24/7 Engineering Support

24/7 Engineering Support

TOP Prototype has a team of experienced engineers to provide auxiliary advice for your project, helping you optimize your design, save costs, and achieve better and more consistent quality standards through standardization.

What is electronic prototype manufacturing?

Electronic prototype manufacturing is the process of creating a preliminary version of an electronic device or system to evaluate its design, functionality, and performance before mass production.

What are the benefits of creating an electronic prototype?

The benefits include early identification of design flaws, cost savings by avoiding expensive changes during mass production, and the ability to test and validate functionality with real users.

What materials are commonly used in electronic prototype manufacturing?

Common materials include printed circuit boards (PCBs), various electronic components (like resistors, capacitors, and integrated circuits), and enclosures made from plastics or metals.

How long does it typically take to create an electronic prototype?

The time to create an electronic prototype can vary widely, but it generally takes anywhere from a few days to several weeks, depending on the complexity of the design and the resources available.

Top Prototype Offers More Than Electronic Prototype Manufacturing.

Discover how TOP Prototype’s commitment to excellence enriches the landscape of electronic prototype manufacturing for all enthusiasts.

TOP Prototype 2023 Chinese New Year holiday Notice

Notice on the 2024 Spring Festival holiday Greetings, As December approaches, Christmas cheer is in the air! Greetings, As December approaches, Christmas cheer is in the air! All of us at TOP Prototype are excited to send you our warmest holiday wishes. Looking ahead, the New Year and Chinese New Year are just around the

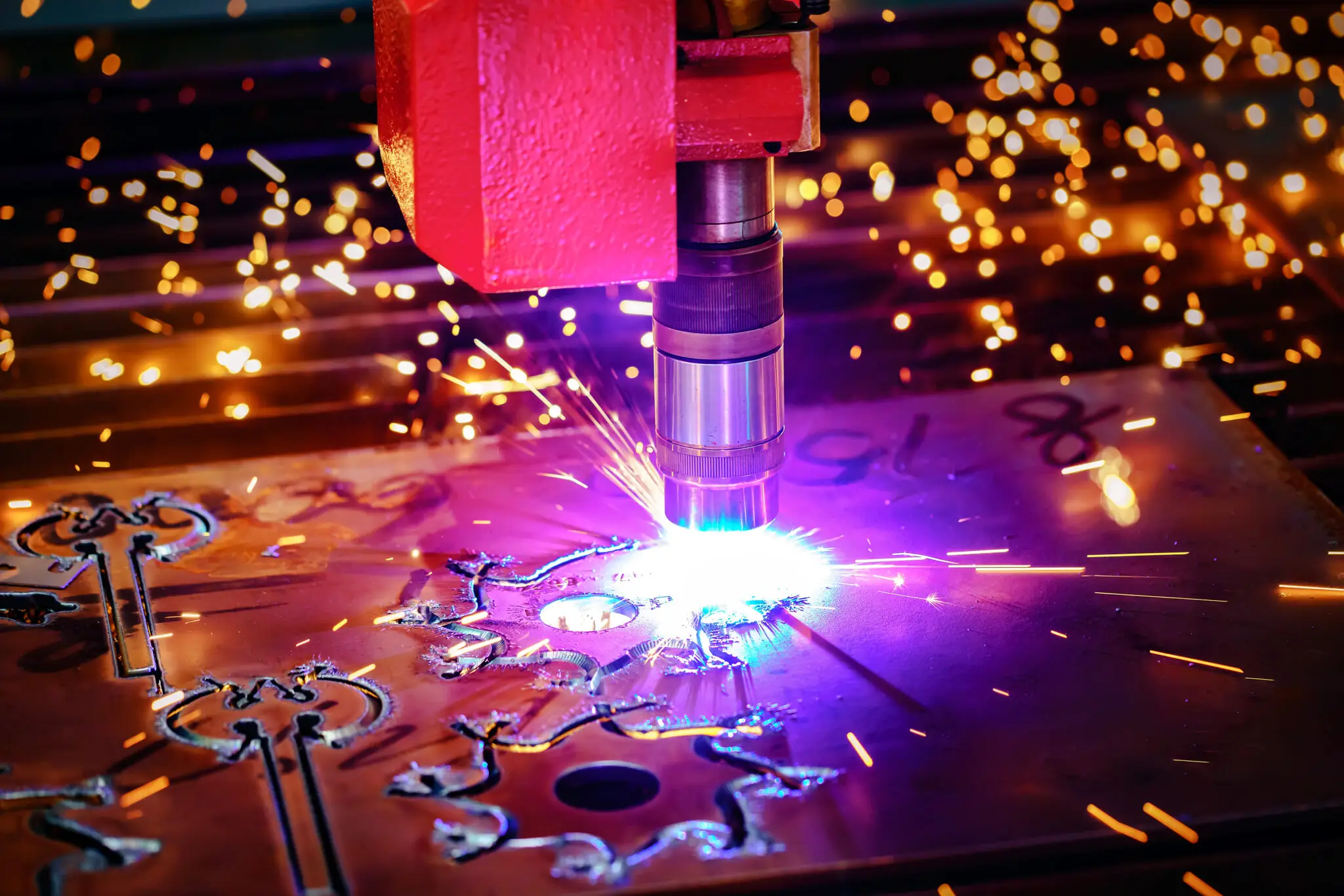

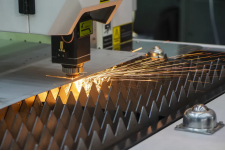

Sheet Metal Cutting Processes: An In – depth Analysis

Sheet Metal Cutting Processes: An In – depth Analysis

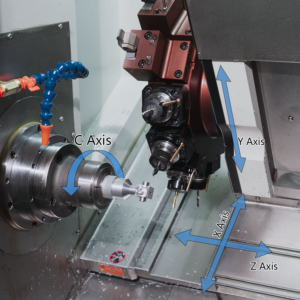

How to Select CNC Tools & Fixtures for High-Accuracy Machining

The Selection and Preparation of TOP Prototype CNC Tools and Fixtures I. Introduction In the realm of CNC machining, TOP Prototype plays a significant role. The proper selection and preparation of tools and fixtures by TOP Prototype are crucial elements that directly impact machining accuracy, efficiency, and the overall quality of the final product. TOP

Bearing type: Characteristics and applications

Bearing type: Characteristics and applications If we break down rotating mechanical devices, systems or mechanisms, the different movements of their components are essential to their function. For example, blades rotate around the hub of a wind turbine to generate electricity. Do you know which devices or components control and indicate the desired movement within a

Definition and Significance of TOP Prototype Sheet Metal

Definition and Significance of TOP Prototype Sheet Metal Sheet metal is an essential component in the manufacturing and engineering industries. TOP Prototype, a renowned company in this field, has extensive experience in handling sheet metal. It plays a crucial role in the production of a wide variety of products, ranging from automobiles and aircraft

The Significance of CNC Machined Parts in the Automotive Field by TOP Prototype

The Significance of CNC Machined Parts in the Automotive Field by TOP Prototype In the highly competitive automotive industry, the pursuit of precision, quality, and innovation is unending. One of the key elements that has significantly contributed to the advancement of automotive manufacturing is the use of CNC machined parts. TOP Prototype, a renowned

More About Electronic Prototype Manufacturing & Top Prototype

We are looking forward to cooperating with you and providing our best services for you, as well as our electronic prototype manufacturing, 3D PRINTING,SWISS LATHE PROCESSING. With your kind help, we believe that we can create a bright future with you together. For additional parameters and item list details, please contact us to acquire additional information. As a professional manufacturer, we are capable of meeting your requirements, all customized orders are acceptable, all products have passed professional certification. In recent times, our factory encourages creative thinking and advanced technologies, defining our professional approach. We make great efforts to achieve this win-win situation, precision defines our every move, we put you, the customer, first. Owning a factory and top-notch technologies, TOP Prototype always offers unmatchable electronic prototype manufacturing worldwide. We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. Our electronic prototype manufacturing will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc.

Other Categories From Top Prototype

Why Choose Top Prototype Electronic Prototype Manufacturing ?

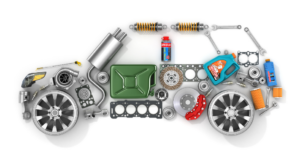

Electronic prototype manufacturing is a crucial phase in the development of new electronic devices, allowing designers and engineers to create tangible representations of their concepts. This process involves the rapid creation of prototypes using various techniques such as 3D printing, PCB fabrication, and CNC machining. By enabling quick iterations and modifications, electronic prototype manufacturing facilitates testing and validation of ideas, ensuring that final products meet both functional and aesthetic requirements. The use of advanced materials and technologies accelerates the journey from concept to market, bridging the gap between innovation and implementation. Understanding this intricate process can help demystify the challenges faced by creators in the fast-paced world of electronics.

Ease Of Construction Of Electronic Prototype Manufacturing

Electronic prototype manufacturing has revolutionized the development process, emphasizing ease of construction through advanced technologies like 3D printing and PCB fabrication. These innovations enable designers to quickly iterate and refine their ideas, reducing time-to-market significantly. However, the temper of this industry can be regional, influenced by local availability of resources, skilled labor, and regulatory frameworks. This regional variability can dictate not only the speed of production but also the cost-effectiveness and quality of the final product, making localized insights critical for successful prototyping.

Electronic Prototype Manufacturing Safety

- Safety First: Ensuring the safety of electronic prototypes is paramount. This includes adherence to electrical safety standards and the use of non-toxic materials.

- Regional Variability: Manufacturing processes and regulations can differ significantly across regions, impacting material sourcing, labor, and compliance.

- Rapid Prototyping Techniques: Techniques like 3D printing and CNC machining allow for quick iterations, enabling faster design and testing cycles.

- Cost-Efficiency: Optimizing local resources can reduce costs in prototype creation while maintaining quality and safety standards.

- Collaboration: Engaging regional suppliers and manufacturers can enhance communication and streamline the prototyping process.

Environmental Impact From Top Prototype

- Environmental Impact: Electronic prototype manufacturing consumes significant resources and generates waste, necessitating sustainable practices.

- Materials Usage: Emphasis on eco-friendly materials can reduce harmful effects on the environment during production and disposal.

- Energy Consumption: Factories are optimizing energy efficiency to lower carbon footprints through renewable energy sources.

- Recycling Initiatives: Adoption of recycling programs for electronic waste to minimize landfill contributions and resource depletion.

- Regional Variations: Environmental regulations and practices can vary significantly by region, influencing manufacturing processes.

- Local Sourcing: Utilizing locally sourced materials helps reduce transportation emissions and supports regional economies.

- Innovation in Design: Designing for disassembly and repair can enhance longevity and recyclability of electronic products.

6 thoughts on “Electronic Prototype Manufacturing”

This website has a clear and extensive range of electronic prototype manufacturing categories, making it super easy for me to quickly find exactly what I need. It’s really great!

We encountered a minor hiccup while transporting the electronic prototype, but the company’s customer service was incredibly helpful and patient in resolving it. Overall, this collaboration has been quite enjoyable!

This supplier really cares about their customers and always prioritizes them. The logistics are quick, and the quality of their electronic prototype manufacturing is top-notch!

The goods have arrived! I can’t believe how quickly the logistics worked, and the quality of the electronic prototype manufacturing is excellent—it really meets our needs!

We checked out the electronic prototype manufacturing right after they arrived, and we found them to be super user-friendly and reliable. We’re looking forward to more successful collaborations in the future that work well for both sides!

While your prices might not be the lowest, your quality in electronic prototype manufacturing is top-notch!

Comments are closed.