Cnc Swiss Machining – Unlocking Profit 40%

Best wholesaling cnc swiss machining from top prototype | chinese supplier discover top prototype! we provide trustworthy cnc swiss machining ,& engaged in cnc swiss machining market for many yrs.

Your Guide To Top Prototype Categories

Best wholesaling cnc swiss machining from top prototype | chinese supplier discover top prototype! we provide trustworthy cnc swiss machining ,& engaged in cnc swiss machining market for many yrs.

Cnc Swiss Machining Boost Your Profit!

Uncover Innovative cnc swiss machining in the selection from TOP Prototype. Make TOP Prototype your trusted partner with cnc swiss machining when searching for cnc swiss machining.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

Explore Customer Reviews For Cnc Swiss Machining: Check Them Out!

We are a global supplier of unparralleled cnc swiss machining to a diverse customer base.

Interested In What Top Prototype Can Offer With Cnc Swiss Machining? Contact Us Now!

Our production top-notch stand out for their high quality, resilience, and user-friendly maintenance. Learn more by visiting our website.

400,000 +

Uniquely designed parts produced 400,000 +

60 +

60 + Countries Countries shipped

15 +

15 + Years in Business

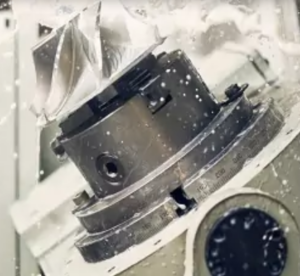

What is CNC Swiss machining?

CNC Swiss machining is a precision manufacturing process that uses computer numerical control (CNC) technology to produce highly accurate and complex parts, typically from bar stock. This method is known for its ability to create small, intricate components with tight tolerances.

What are the advantages of CNC Swiss machining?

The advantages of CNC Swiss machining include high precision, reduced production time, the ability to machine complex geometries, and minimal material waste. It is particularly effective for producing small parts in large quantities.

What types of materials can be machined using CNC Swiss machining?

CNC Swiss machining can work with a variety of materials, including metals like stainless steel, aluminum, brass, and copper, as well as plastics and other materials. The choice of material often depends on the specific application and desired properties of the final part.

What industries commonly use CNC Swiss machining?

CNC Swiss machining is commonly used in industries such as aerospace, automotive, medical devices, electronics, and precision engineering, where high precision and reliability are critical for component performance.

Want To Know More About Cnc Swiss Machining?

Explore how TOP Prototype enhances your understanding of cnc swiss machining through cutting-edge solutions and expert knowledge.

7 Reasons for Embracing CNC Rapid Prototyping

Computer Numerical Control (CNC) rapid prototyping refers to the use of CNC machining technology to create prototypes quickly and accurately from a digital design. The process involves converting 3D models into machine code, which then directs CNC equipment to cut or shape materials into physical prototypes. CNC rapid prototyping has become a vital part of

Unraveling the Wonders of TOP Prototype Electroplating: Process, Applications, and Impact

Unraveling the Wonders of TOP Prototype Electroplating: Process, Applications, and Impact What is Electroplating? TOP Prototype is a company that may utilize electroplating in its operations. Electroplating is a process that uses an electric current to deposit a thin layer of metal onto another metal or other conductive surface. In electroplating carried out

Quality Inspection of TOP Prototype Products

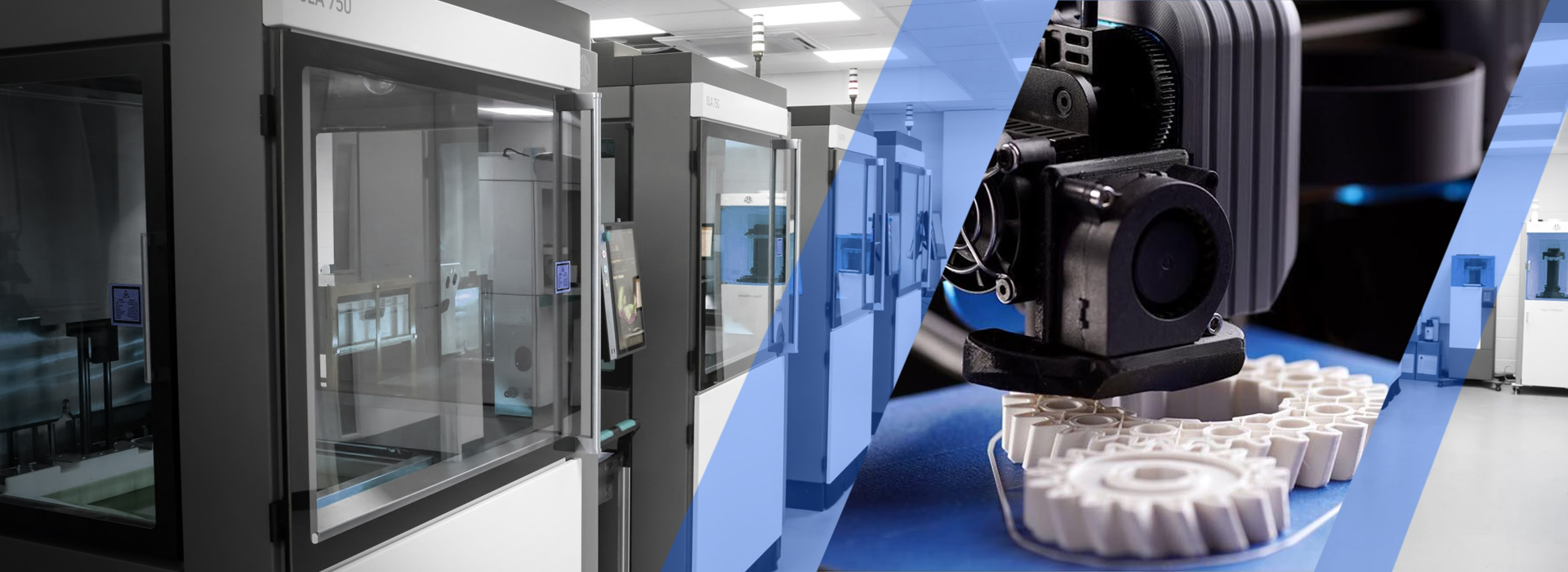

Quality Inspection of TOP Prototype Products In the highly competitive manufacturing industry, ensuring the quality of products is of utmost importance. TOP Prototype, a company specializing in various manufacturing processes such as CNC machining parts, injection molding, sheet metal fabrication, silicone rubber molding, and 3D printing, has established a comprehensive and stringent quality inspection system

How to Select CNC Tools & Fixtures for High-Accuracy Machining

The Selection and Preparation of TOP Prototype CNC Tools and Fixtures I. Introduction In the realm of CNC machining, TOP Prototype plays a significant role. The proper selection and preparation of tools and fixtures by TOP Prototype are crucial elements that directly impact machining accuracy, efficiency, and the overall quality of the final product. TOP

Sheet Metal Processing Materials: Characteristics, Applications, and Innovations

Sheet Metal Processing Materials: Characteristics, Applications, and Innovations Sheet metal processing is a vital part of modern manufacturing, and the choice of materials plays a decisive role in the quality and performance of the final products. TOP Prototype, a distinguished company in this domain, has in – depth knowledge and extensive experience in handling

High – Precision Sheet Metal Bending in TOP Prototype Company

High – Precision Sheet Metal Bending in TOP Prototype Company Ⅰ. Introduction In the modern manufacturing industry, sheet metal bending plays a crucial role in the production process. TOP Prototype, as a well – known company in this field, has extensive experience and advanced techniques in sheet metal bending operations. This paper will explore the

More About Cnc Swiss Machining & Top Prototype

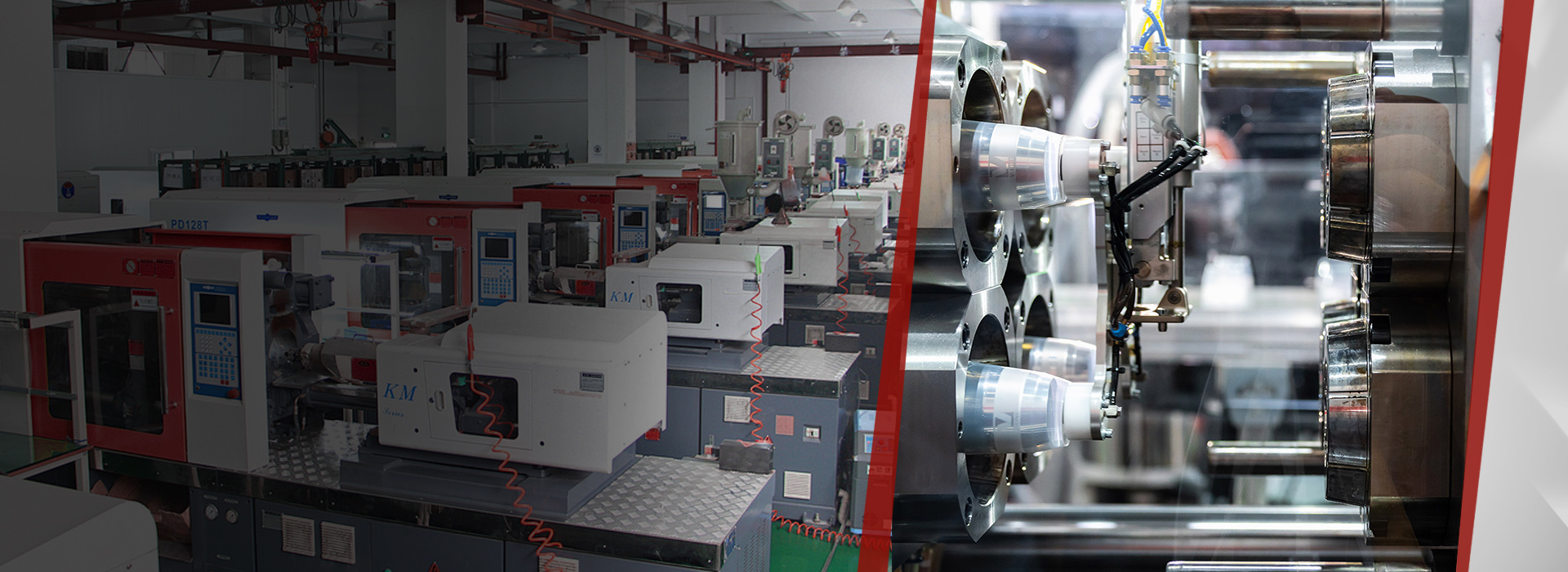

Nowadays with the trend of internationalization, we’ve got decided to reach a broader audience. Our cnc swiss machining will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc. You are most welcome to come to China, to our city and our factory! Call or E-mail us your specifications or inquiries right now. Over the past few years, our factory absorbed and digested integrated advanced technologies, exceeding the industry standard. Owning a factory and top-notch technologies, TOP Prototype always offers unmatchable cnc swiss machining worldwide. Our aim is to help customers realize their goals, we innovate with integrity, putting you first is our mission. As a professional manufacturer, we are capable of meeting your requirements, all customized orders are acceptable, all products have passed professional certification. We are looking forward to cooperating with you and providing our best services for you, as well as our cnc swiss machining, 3D PRINTING,5-AXIS CNC MACHINING.

Other Categories From Top Prototype

Why Choose Top Prototype Cnc Swiss Machining ?

CNC Swiss machining is where precision meets speed! This high-tech process uses computer-controlled lathes to create small, complex parts with super tight tolerances. Think of it as the ultimate tool for manufacturing anything from tiny medical devices to intricate aerospace components. With a Swiss machine, parts are held in a rotating spindle, allowing for multiple cuts and operations to happen in one go. It’s like multitasking for metal! So, if you’re looking to whip up precision parts quickly without sacrificing quality, CNC Swiss machining is your go-to solution. It’s fast, efficient, and super reliable—perfect for those rapid prototyping projects where time is of the essence!

Energy Efficiency Of Cnc Swiss Machining

In the realm of rapid prototyping, CNC Swiss machining emerges as a game-changer, harnessing superior energy efficiency like never before! This innovative manufacturing process not only maximizes material utilization but also minimizes waste and energy consumption during operation. With its ability to perform complex tasks in a singular setup, it drastically reduces cycle times while maintaining precision. Embrace the future of machining where performance and sustainability go hand in hand, revolutionizing how we think about production!

Cnc Swiss Machining Unique Features

- Precision Engineering: CNC Swiss machining delivers unparalleled accuracy, making it ideal for intricate designs and tight tolerances.

- Complex Geometries: Unique capabilities allow for the production of complex, multi-faceted components without the need for secondary operations.

- Efficiency: High-speed machining significantly reduces cycle times, optimizing production and maximizing output!

- Material Versatility: Works wonders with a variety of materials, from metals to plastics, ensuring adaptability for diverse applications.

- Reduced Waste: The precision of CNC Swiss machining minimizes material wastage, contributing to cost savings and sustainability!

- Automated Processes: Integration of automated loading and unloading enhances productivity, allowing for continuous operation and less downtime.

Design From Top Prototype

- Precision Engineering: CNC Swiss machining revolutionizes the manufacturing process with unparalleled accuracy, crafting intricate designs with utmost precision.

- Design Flexibility: This method accommodates complex geometries, allowing designers to push boundaries and innovate without limits!

- Material Versatility: Suitable for a wide range of materials, from metals to plastics, enabling diverse applications across industries!

- Rapid Prototyping: Swift turnaround times facilitate faster iterations, empowering teams to rapidly prototype and test designs!

- Cost-Effective: Reduces waste and optimizes production efficiency, leading to significant cost savings while maintaining quality!

- Advanced Technology: Incorporates cutting-edge software and machinery, enhancing quality control and boosting productivity!

8 thoughts on “Cnc Swiss Machining”

The essence of creativity, dependability, entrepreneurship, and meticulousness is woven throughout their CNC Swiss machining product development and manufacturing process, as evident from our recent order.

This is my first order with them, and I’m really happy with the service from the initial consultation all the way to receiving my CNC Swiss machining products. They’re great quality, and I’ll definitely be coming back for more!

The seller provides excellent service, and I look forward to the chance to work together on CNC Swiss machining in the future!

You’ll really enjoy shopping with this company! They do an awesome job answering questions about CNC Swiss machining, keeping you updated on logistics, and providing great after-sales support.

Sticking to the idea of mutual benefits, we’ve had a great and successful deal with our CNC Swiss machining. We believe this makes us the perfect business partners!

This supplier has a well-rounded system for R&D, production, and sales. Throughout our collaboration, we’ve benefited from the support of a skilled technical team while working with their CNC Swiss machining products.

The CNC Swiss machining is top-notch and does the job perfectly, making it a great value for the price!

This company has been rolling out an increasing number of top-notch CNC Swiss machining products thanks to their ongoing research and innovation, and we’re excited to see them keep up the great work!

Comments are closed.