Casting Rapid Prototyping | Global-Minded China Manufacturer 2024

Casting rapid prototyping from the best manufacturer & wholesaler top prototype. discover top prototype! we provide innovative casting rapid prototyping ,& engaged in casting rapid prototyping market for many yrs.

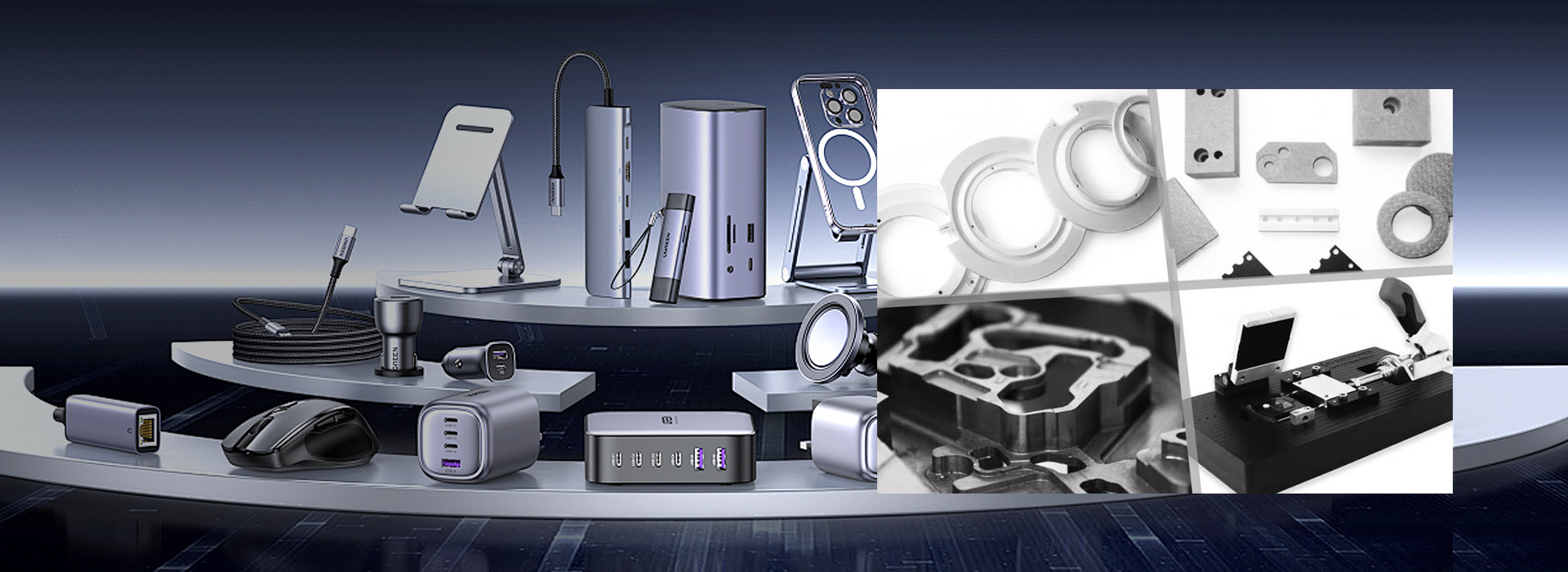

Introducing Our Top Prototype Category

Casting rapid prototyping from the best manufacturer & wholesaler top prototype. discover top prototype! we provide innovative casting rapid prototyping ,& engaged in casting rapid prototyping market for many yrs.

Casting Rapid Prototyping – Elevate Your Business With Quality!

Get your hands on TOP Prototype’s Premium casting rapid prototyping. TOP Prototype has top quality casting rapid prototyping worth considering if you need casting rapid prototyping.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

Explore Customer Reviews For Casting Rapid Prototyping: Check Them Out!

We are a global supplier of highly recommended casting rapid prototyping to a diverse customer base.

Eager To Learn More About Casting Rapid Prototyping? Connect With Us Now!

The worth buying we offer are synonymous with high quality, longevity, and effortless maintenance. Check out our website for extensive details.

400,000 +

Uniquely designed parts produced 400,000 +

60 +

60 + Countries Countries shipped

15 +

15 + Years in Business

What is casting rapid prototyping?

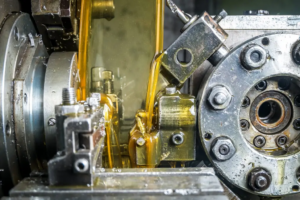

Casting rapid prototyping is a manufacturing process that combines traditional casting techniques with rapid prototyping technologies to quickly create molds or parts for casting. This approach allows for faster development and iteration of designs compared to conventional methods.

What are the advantages of using casting rapid prototyping?

The advantages of casting rapid prototyping include reduced lead times, lower costs for small production runs, the ability to quickly test and validate designs, and the flexibility to make design changes without significant delays.

What materials are commonly used in casting rapid prototyping?

Common materials used in casting rapid prototyping include thermoplastics for creating molds, metal powders for metal casting, and various resin materials that can be used in 3D printing processes to create prototype parts.

How does casting rapid prototyping impact product development?

Casting rapid prototyping significantly impacts product development by enabling faster iteration cycles, allowing for more frequent testing and feedback, and speeding up the time-to-market for new products, which is crucial in competitive industries.

Want To Know More About Casting Rapid Prototyping?

Explore how TOP Prototype enhances your understanding of casting rapid prototyping through cutting-edge solutions and expert knowledge.

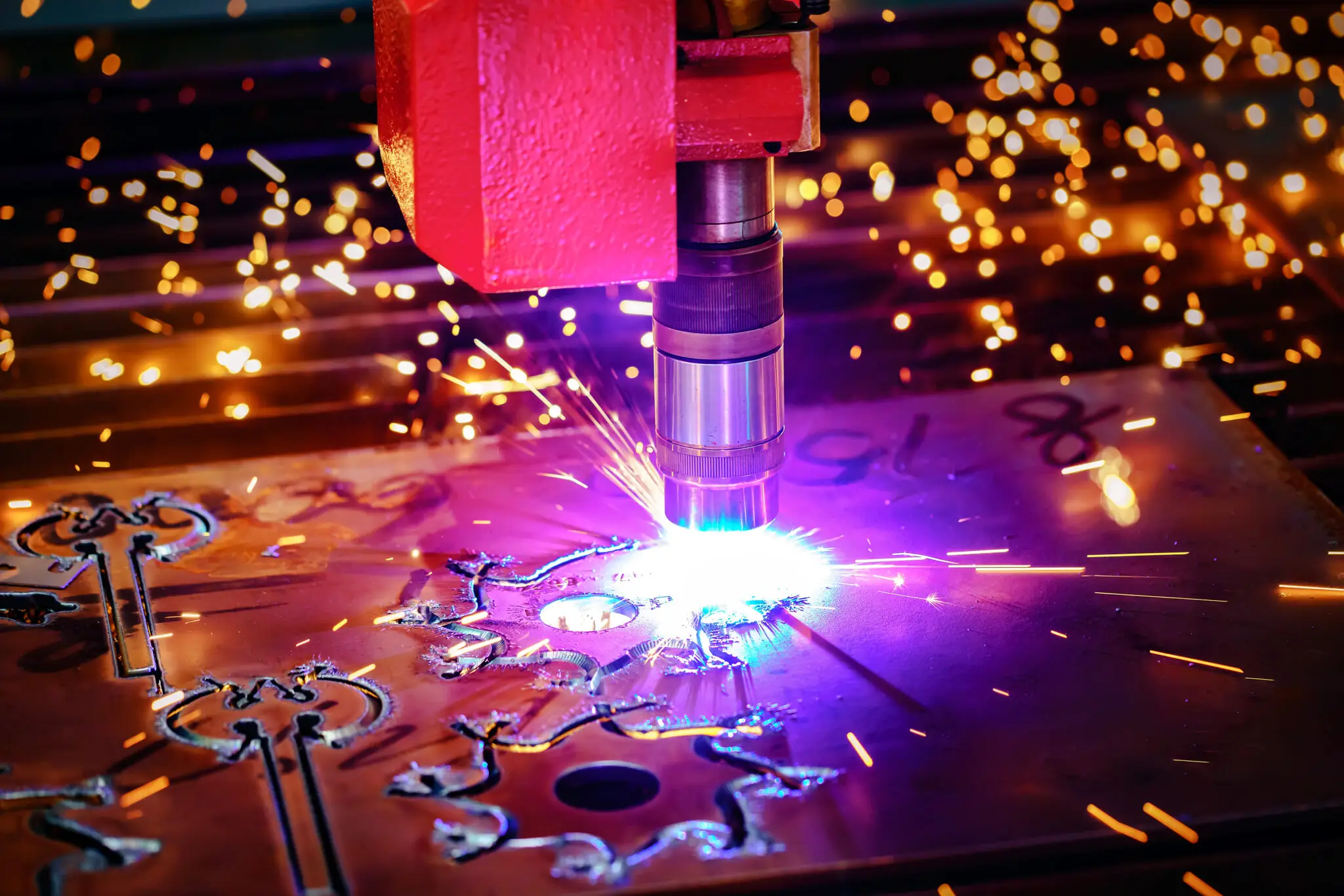

Sheet Metal Cutting Processes: An In – depth Analysis

Sheet Metal Cutting Processes: An In – depth Analysis

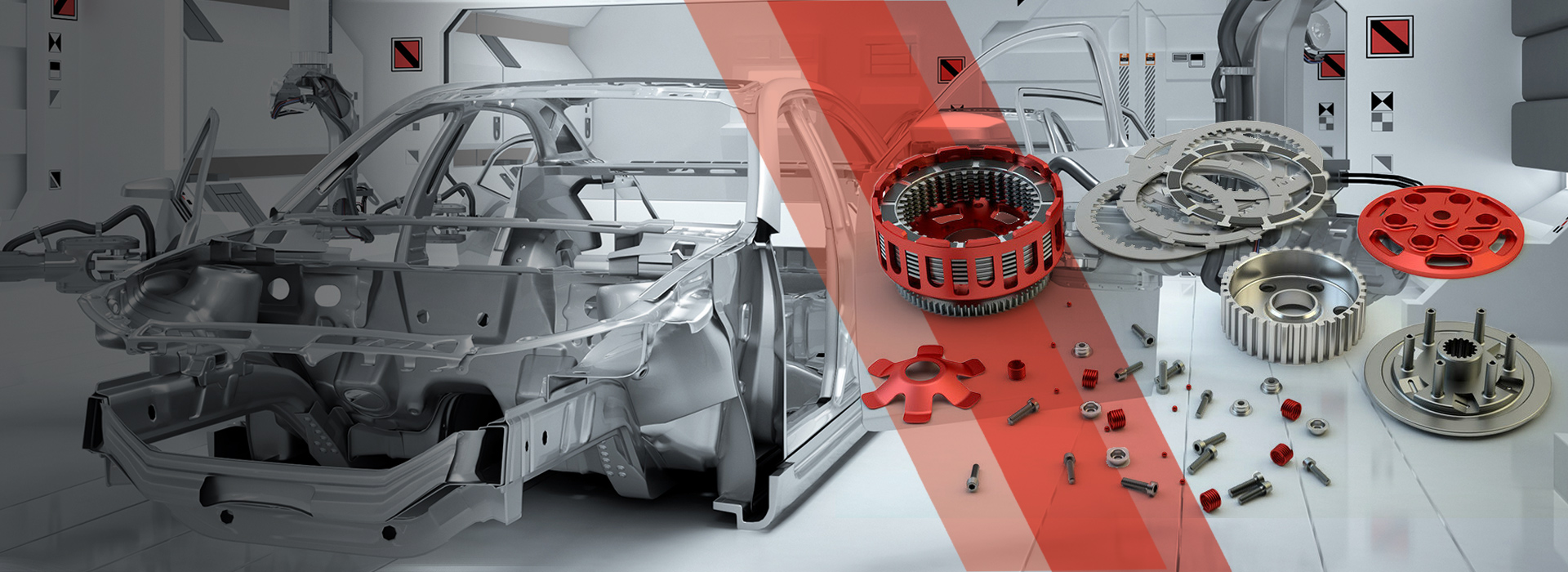

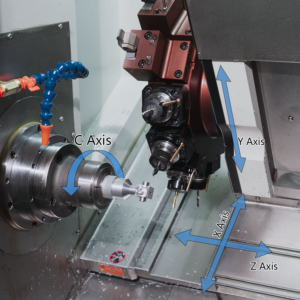

The Significance of CNC Machined Parts in the Automotive Field by TOP Prototype

The Significance of CNC Machined Parts in the Automotive Field by TOP Prototype In the highly competitive automotive industry, the pursuit of precision, quality, and innovation is unending. One of the key elements that has significantly contributed to the advancement of automotive manufacturing is the use of CNC machined parts. TOP Prototype, a renowned

What is die casting? Process, material, application, cost

What is die casting? Process, material, application, cost Die casting turns vision into reality, enabling the precise manufacture of complex metal components that are the backbone of today’s leading industries from automotive to electronics. At the heart of the process is the high-pressure injection of molten metal into elaborate molds, laying the foundation for innovation

The Crucial Role of CNC Machined Parts in the Medical Industry by TOP Prototype

The Crucial Role of CNC Machined Parts in the Medical Industry by TOP Prototype The medical industry is constantly evolving, driven by the need for more precise, reliable, and innovative solutions to improve patient care and treatment outcomes. One of the key elements contributing to this progress is the use of CNC machined

How to Select CNC Tools & Fixtures for High-Accuracy Machining

The Selection and Preparation of TOP Prototype CNC Tools and Fixtures I. Introduction In the realm of CNC machining, TOP Prototype plays a significant role. The proper selection and preparation of tools and fixtures by TOP Prototype are crucial elements that directly impact machining accuracy, efficiency, and the overall quality of the final product. TOP

Bearing type: Characteristics and applications

Bearing type: Characteristics and applications If we break down rotating mechanical devices, systems or mechanisms, the different movements of their components are essential to their function. For example, blades rotate around the hub of a wind turbine to generate electricity. Do you know which devices or components control and indicate the desired movement within a

More About Casting Rapid Prototyping & Top Prototype

We are looking forward to cooperating with you and providing our best services for you, as well as our casting rapid prototyping, 3D PRINTING,SWISS LATHE PROCESSING. Nowadays with the trend of internationalization, we’ve got decided to reach a broader audience. Our casting rapid prototyping will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc. While in the past few years, our factory absorbed and digested integrated advanced technologies, defining our professional approach. Our experienced R&D team is here to provide you with professional support, feel free to tell us your special requests or concerns, each product has been professionally certified to meet industry standards. Owning a factory and top-notch technologies, TOP Prototype always offers unmatchable casting rapid prototyping worldwide. We sincerely welcome clients from at home and abroad, innovation is our soul and spirit, we put you, the customer, first. Your support continuously inspires us. So please do not hesitate to contact us for your need.

Other Categories From Top Prototype

Why Choose Top Prototype Casting Rapid Prototyping ?

Casting rapid prototyping is an innovative approach that combines the speed of rapid prototyping techniques with the enduring qualities of traditional casting methods. This process allows designers and engineers to quickly create and test prototypes, enabling them to refine their concepts and bring products to market faster. By using advanced materials and additive manufacturing technologies, casting rapid prototyping produces highly accurate and detailed models, which can then be used for functional testing or as molds for final production. This method not only accelerates the design process but also reduces costs and minimizes waste, making it an essential tool in modern manufacturing.

Ease Of Construction Of Casting Rapid Prototyping

Casting rapid prototyping is an efficient method for creating complex parts quickly and accurately. It allows designers to produce high-quality prototypes with ease of construction, often requiring minimal tooling. This technique involves pouring molten material into a mold, which can be made from various substances, enhancing versatility. The process promotes efficiency and reduces lead times, making it an ideal choice for testing designs and materials in a wide range of applications. Its straightforward approach ensures that even those new to prototyping can find success in bringing their ideas to life.

Casting Rapid Prototyping Cost-Effectiveness

- Cost-Effectiveness: Casting rapid prototyping significantly reduces production costs by minimizing material waste and labor expenses.

- Faster Turnaround: Rapid prototyping allows for quicker production cycles, enabling faster product development and market entry.

- Low Initial Investment: Unlike traditional manufacturing methods, casting requires less upfront investment, making it accessible for small businesses and startups.

- Versatile Materials: A wide range of materials can be used in casting, allowing for flexibility in design and functionality while keeping costs down.

- Iterative Design: Rapid prototyping enables easy modifications and iterations, further enhancing cost-effectiveness by reducing the need for complete reworks.

Reliability From Top Prototype

- Reliability: Casting rapid prototyping offers consistent and dependable results, ensuring that prototypes perform as expected.

- Temperature Control: Precise temperature management during the casting process is crucial for maintaining material integrity and achieving optimal results.

- Material Versatility: Various materials can be used, allowing for the production of prototypes with different properties to suit specific applications.

- Speed of Production: Rapid prototyping significantly reduces production time, enabling faster iterations and quicker feedback.

- Cost Efficiency: Lower costs compared to traditional manufacturing methods make it accessible for a wide range of projects.

10 thoughts on “Casting Rapid Prototyping”

This company has an incredibly dedicated service attitude like no other we’ve encountered, and they work super efficiently. They treat us like friends and always keep our needs in mind when it comes to casting rapid prototyping!

I’m really happy we decided to go with this company after some thought; they truly deliver on trustworthiness, especially for casting rapid prototyping!

Apologies for the delay in getting back to you! It took us a few days to confirm, but our guests are really happy with the casting rapid prototyping items.

The casting rapid prototyping arrived the very next day, and setting it up was a breeze!

The quality is excellent, even better than I anticipated! The packaging was really thoughtful, making for a delightful experience overall!

We’ve collaborated with this company multiple times, and each time their teams show impressive professionalism. They consistently deliver high-quality casting rapid prototypes right on schedule!

The company surprised us by delivering the casting rapid prototyping products ahead of schedule, and we were really impressed with their quality!

It’s been a great experience working together, and I look forward to purchasing casting rapid prototyping from here again in the future!

The way this company operates is super streamlined, so our purchases for casting rapid prototyping are always spot on—it’s fantastic!

We’ve enjoyed collaborating with you for many years and are truly impressed by your top-notch craftsmanship and professional team. We look forward to continuing our partnership in casting rapid prototyping!

Comments are closed.