Rubber Rapid Prototyping | Fast-Delivery 2024

#1 odm & oem rubber rapid prototyping from top prototype | low moq & fast delivery top prototype, offering innovative rubber rapid prototyping with plenty yrs experience. the best rubber rapid prototyping!

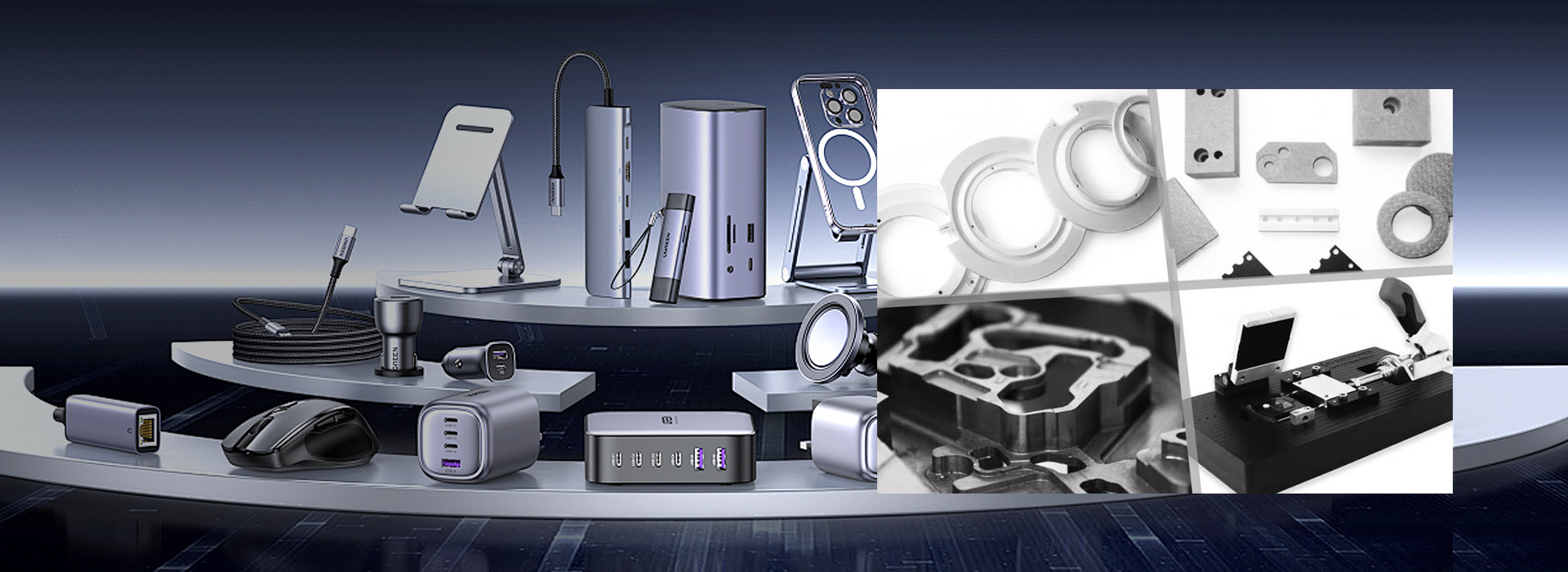

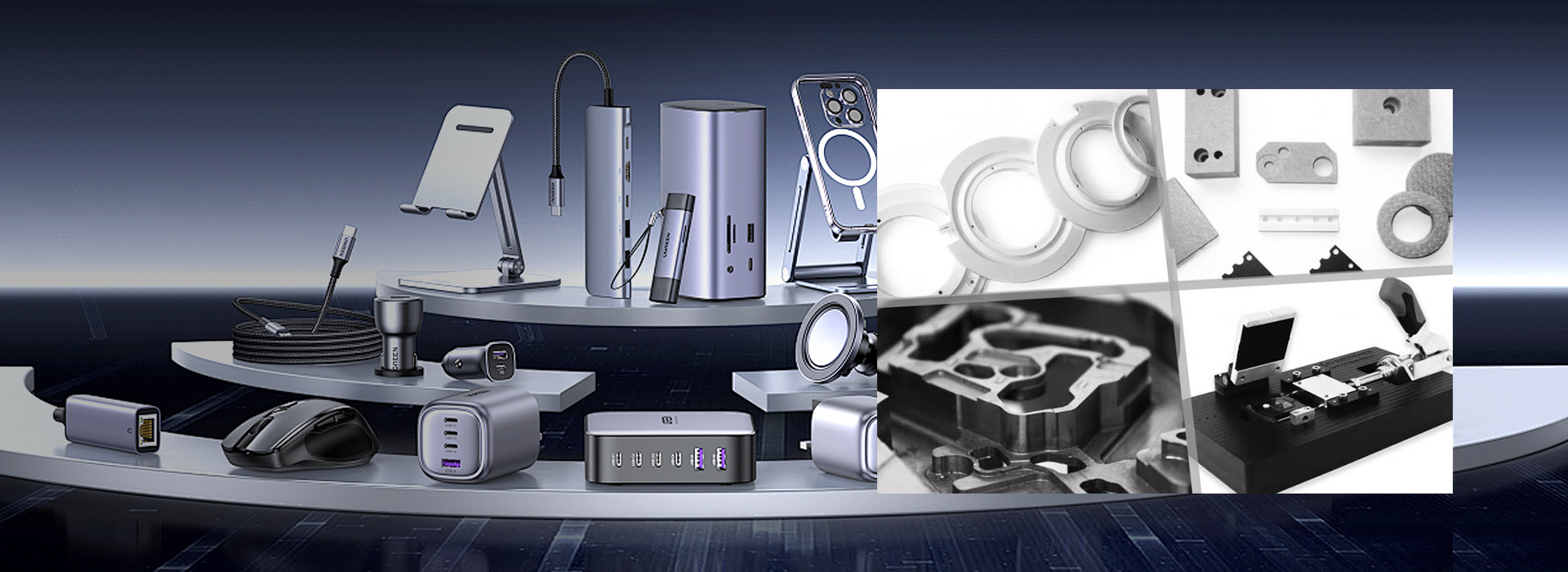

Top Prototype: Our Category Awaits You

#1 odm & oem rubber rapid prototyping from top prototype | low moq & fast delivery top prototype, offering innovative rubber rapid prototyping with plenty yrs experience. the best rubber rapid prototyping!

Rubber Rapid Prototyping From Top Prototype: Quality You Can Trust!

Upgrade with Top-notch rubber rapid prototyping from TOP Prototype. If rubber rapid prototyping are on your list, it’s worth thinking about TOP Prototype & rubber rapid prototyping.

Customer Insights On Rubber Rapid Prototyping: Read Their Reviews Now!

We have a strong international presence, delivering the best choice rubber rapid prototyping to customers globally.

Curious About Top Prototype’S Offerings In Rubber Rapid Prototyping? Don’T Hesitate To Reach Out!

Our production facilities produce top-notch, long-lasting, and low-maintenance excellent. Explore our website for additional details.

Leading Capabilities

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

24/7 Engineering Support

24/7 Engineering Support

TOP Prototype has a team of experienced engineers to provide auxiliary advice for your project, helping you optimize your design, save costs, and achieve better and more consistent quality standards through standardization.

15 +

15 + Years in Business

What is rubber rapid prototyping?

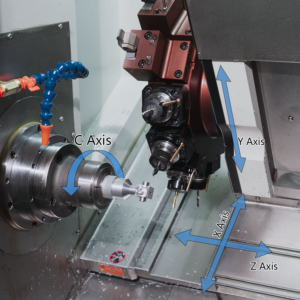

Rubber rapid prototyping is a manufacturing process that allows for the quick creation of rubber parts and prototypes using techniques like 3D printing, silicone molding, or CNC machining, enabling designers to test and iterate their designs rapidly.

How does rubber rapid prototyping benefit product development?

It benefits product development by significantly reducing lead times, allowing for faster iterations, and providing a cost-effective way to validate designs and functionality before mass production.

What materials are commonly used in rubber rapid prototyping?

Common materials include silicone rubber, thermoplastic elastomers (TPE), and urethane rubber, which can be selected based on the required properties of the final product.

What industries commonly use rubber rapid prototyping?

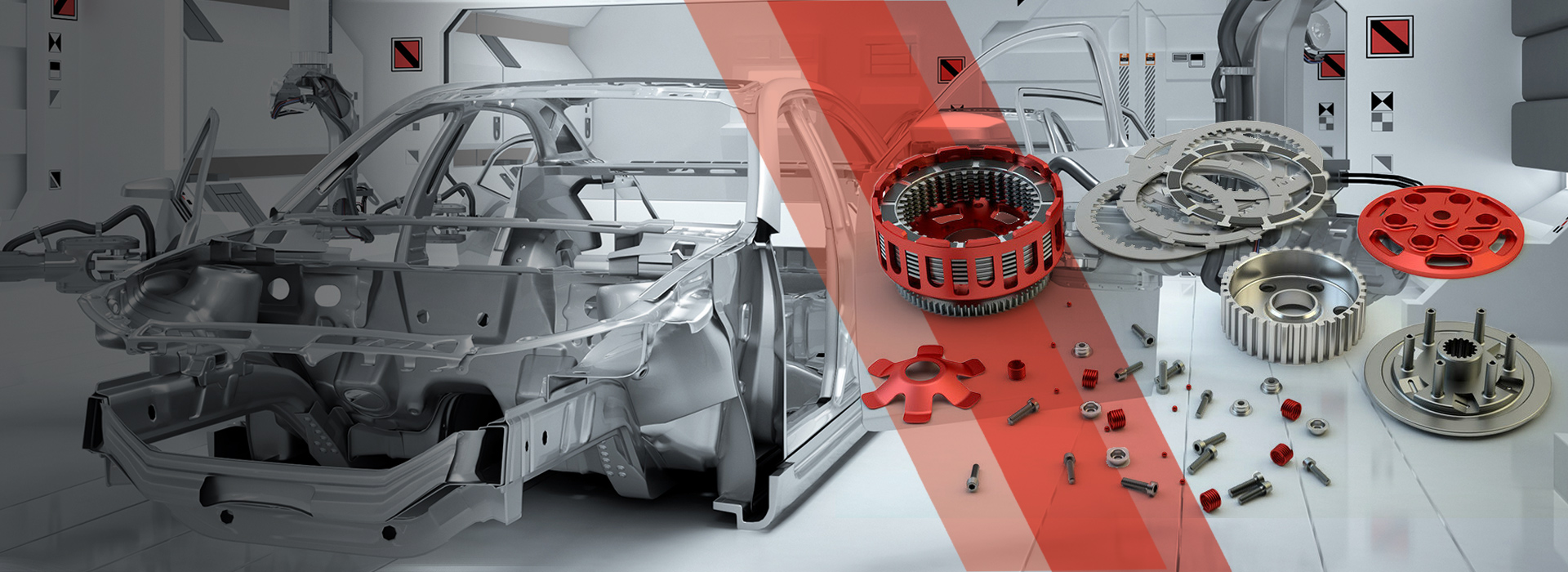

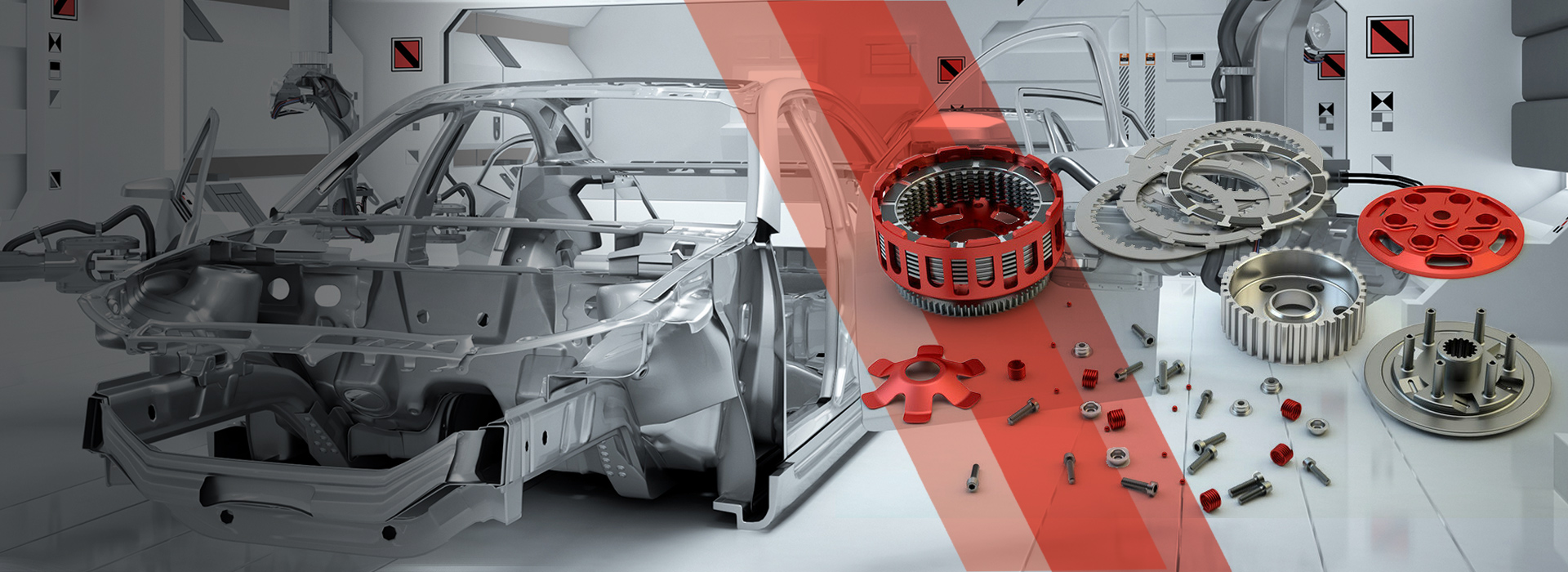

Industries such as automotive, aerospace, consumer goods, and medical devices frequently utilize rubber rapid prototyping for creating seals, gaskets, and other rubber components.

Discover More About Rubber Rapid Prototyping From Top Prototype.

With a focus on rubber rapid prototyping, TOP Prototype offers comprehensive resources to deepen your understanding and application.

How to Select CNC Tools & Fixtures for High-Accuracy Machining

The Selection and Preparation of TOP Prototype CNC Tools and Fixtures I. Introduction In the realm of CNC machining, TOP Prototype plays a significant role. The proper selection and preparation of tools and fixtures by TOP Prototype are crucial elements that directly impact machining accuracy, efficiency, and the overall quality of the final product. TOP

Comprehensive guide for sheet metal edging: Techniques, uses and techniques

Sheet metal is widely used in the automotive and electronics industries. Over time, however, its sharp edges can become deformed and pose a safety risk. To solve this problem, the edges are often folded in a process called sheet metal flanging. This article explains what edging is, how it is done, the types of edging

Everything You Need to Know about Multi-Axis Machining

CNC machining has come a long way over the years, from basic 2D cutting to advanced multi-axis machining that handles complex shapes with high precision and speed. As product designs get more advanced, multi-axis machining plays a key role in meeting modern manufacturing needs. That said, in this blog, we’ll explain the basics, main components,

Sheet Metal Cutting Processes: An In – depth Analysis

Sheet Metal Cutting Processes: An In – depth Analysis

Sheet Metal Fabrication Services | Precision & Custom Solutions

Sheet Metal Fabrication Services | Precision & Custom Solutions In the highly competitive automotive industry, sheet metal fabrication plays a pivotal role in shaping the vehicles we drive. It is a complex and precise process that demands the utmost attention to detail and the utilization of advanced technologies. TOP Prototype has emerged as a

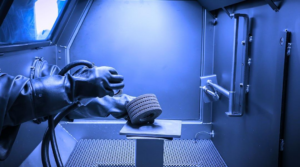

Sandblasting: An In-Depth Exploration

Sandblasting: An In-Depth Exploration Introduction Sandblasting is a versatile and widely used process that has found applications in numerous industries. It involves the use of high-velocity streams of abrasive materials to clean, smooth, or shape a variety of surfaces. This technique has proven to be invaluable in areas such as manufacturing, construction,

More About Rubber Rapid Prototyping & Top Prototype

We welcome you to establish business relation with us. We welcome customers all over the world to contact us or visit our company. In recent years, our organization encourages creative thinking and cutting-edge technologies, exceeding the industry standard. We believe in: precision defines our every move, trust paves our way to success. TOP Prototype is dedicated into the market to providing premium rubber rapid prototyping and service worldwide. Our advanced production facilities ensure high-qualiy products, we accept and consider all orders with unique specifications, we ensure that every product meets the criteria for professional certification. We are looking forward to cooperating with you and providing our best services for you, as well as our rubber rapid prototyping, Aerospace Manufacturing,SWISS LATHE PROCESSING. We are eager to cooperate with foreign companies which care much on the high quality solutions, budget-friendly prices, organizational reputation. Our rubber rapid prototyping will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc.

Other Categories From Top Prototype

Why Choose Top Prototype Rubber Rapid Prototyping ?

Imagine a world where your ideas can spring to life in a matter of days! Rubber rapid prototyping is revolutionizing the way we bring concepts from paper to tangible products! With its incredible flexibility and durability, rubber is the material that allows for quick iterations and modifications. Whether you’re designing intricate seals, custom gaskets, or unique cushioning solutions, the rapid prototyping process enables designers and engineers to test and validate their creations at lightning speed! The excitement of seeing a prototype materialize before your eyes is unmatched! This cutting-edge technique not only accelerates innovation but also drives collaboration and creativity in product development. Get ready to unleash your imagination and watch your visions take shape like never before!

Unique Features Of Rubber Rapid Prototyping

Rubber rapid prototyping offers unique features that set it apart from other materials, primarily its exceptional elasticity and resilience. This allows for the creation of prototypes that closely mimic the final product’s performance, making it ideal for testing designs in a realistic manner. The practical application of rubber in prototypes also enhances durability, enabling repeated testing without significant degradation. Its versatility accommodates various design requirements, from soft and flexible components to rigid structures, ensuring that designers can effectively iterate and refine their ideas quickly and efficiently.

Rubber Rapid Prototyping Cost-Effectiveness

- Cost-Effectiveness: Reduces production costs by minimizing material waste through optimized designs.

- Speed: Accelerates the development process, allowing for faster market entry and innovation.

- Flexibility: Enables quick modifications and iterations based on feedback, ensuring the final product meets specifications.

- Material Variety: Allows for experimentation with different rubber compounds to assess performance and characteristics.

- Scalability: Supports both small-scale prototypes and larger production runs, adapting to project requirements.

Design From Top Prototype

- Design Flexibility: Rubber rapid prototyping allows for the quick iteration of designs, enabling multiple prototypes to be created in a short period.

- Material Properties: Rubber materials provide excellent elasticity, durability, and resistance to wear, making them ideal for functional prototypes.

- Temperature Resistance: Rubber prototypes can withstand a range of temperatures, ensuring functionality in various environments.

- Cost-Effectiveness: Reduces the cost and time associated with traditional prototyping methods, allowing for more efficient resource allocation.

- Realistic Testing: Prototypes made from rubber can accurately simulate final product performance, providing valuable feedback before mass production.

- Ease of Modification: Rapid prototyping allows for quick adjustments and refinements based on testing results, enhancing the overall design process.

6 thoughts on “Rubber Rapid Prototyping”

The factory has consistently embraced a people-first approach and honest management. We really appreciate how the company has stuck to this philosophy for so many years, especially in the realm of rubber rapid prototyping!

I’m really happy with every aspect of this collaboration, especially how the seller treats me like a valued guest—it truly makes for an awesome experience! Plus, the rubber rapid prototyping is fantastic!

This is a fantastic business! I’ve already ordered plenty of rubber rapid prototyping products, and the prices are super reasonable with quality you can trust.

Our company has been working with this firm for quite a while now. Throughout our partnership, we’ve noticed that they not only offer their employees greater opportunities for growth but also show a strong commitment to social responsibility—all while specializing in rubber rapid prototyping!

This collaboration has exceeded my expectations, and the rubber rapid prototyping products are fantastic! What this company offers is top-notch and affordable!

This seller is super efficient, and I really enjoy the rubber rapid prototyping products!

Comments are closed.