Rapid Prototyping Plastic | Elevate Profit Margin: 30%

Discover rapid prototyping plastic from top prototype – quality and style combined! search top prototype, who provides innovative rapid prototyping plastic. we devote to rapid prototyping plastic market for several yrs.

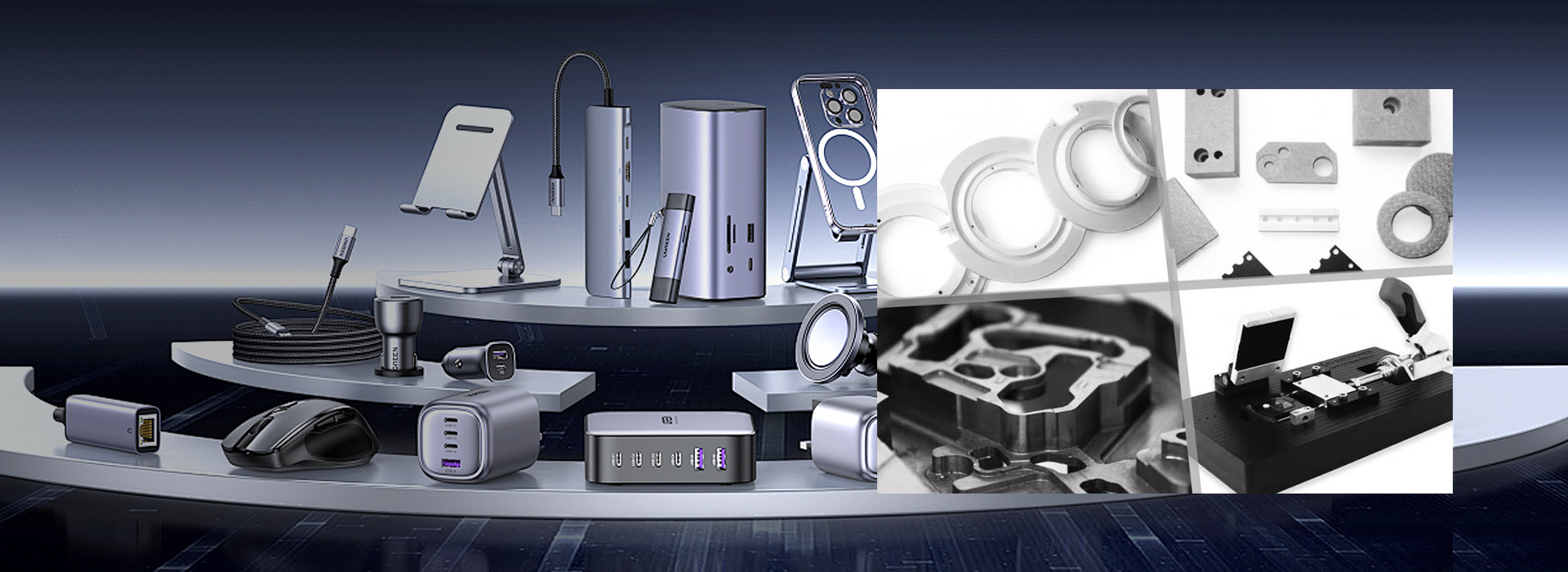

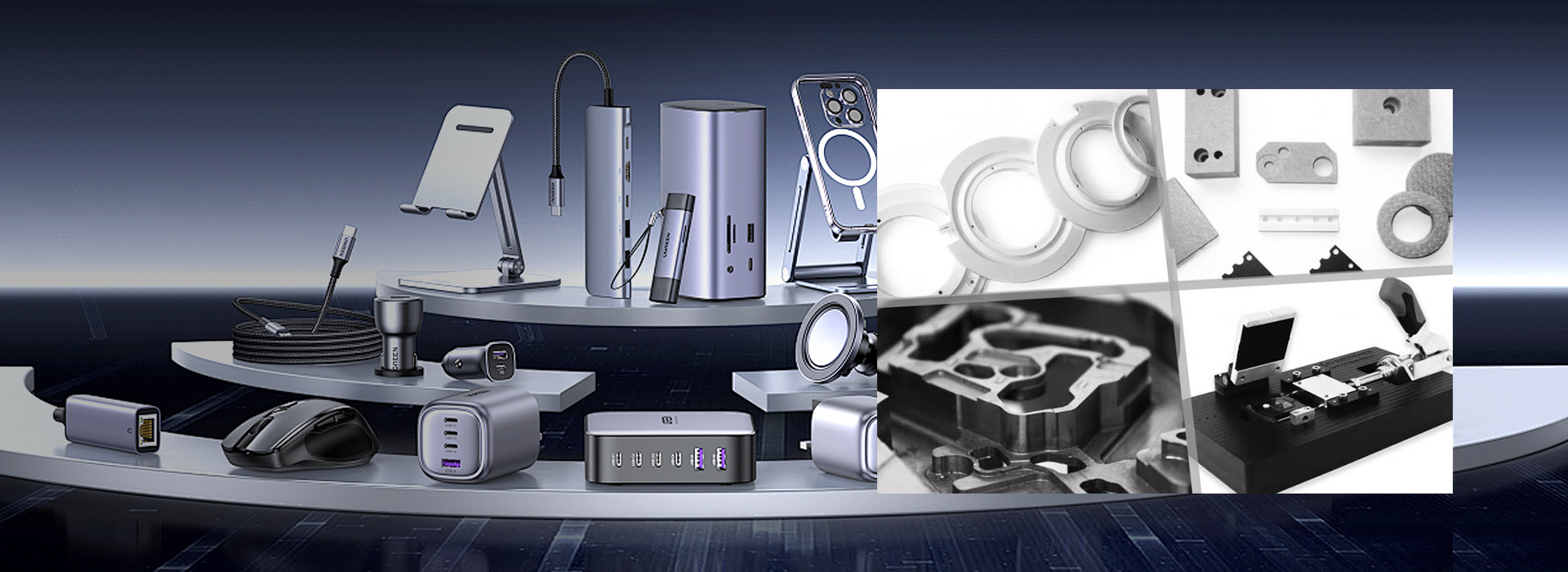

Category From Top Prototype

Discover rapid prototyping plastic from top prototype – quality and style combined! search top prototype, who provides innovative rapid prototyping plastic. we devote to rapid prototyping plastic market for several yrs.

Rapid Prototyping Plastic – Top Prototype Offers Good Quality!

Get your hands on TOP Prototype’s Top-notch rapid prototyping plastic. If rapid prototyping plastic are your priority, TOP Prototype offers reliable rapid prototyping plastic to explore.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

Customer Insights On Rapid Prototyping Plastic: Read Their Reviews Now!

Our the best choice rapid prototyping plastic are sought after by customers worldwide.

Want To Know More About Rapid Prototyping Plastic And How It Can Benefit You?

Our production great value for money stand out for their high quality, resilience, and user-friendly maintenance. Learn more by visiting our website.

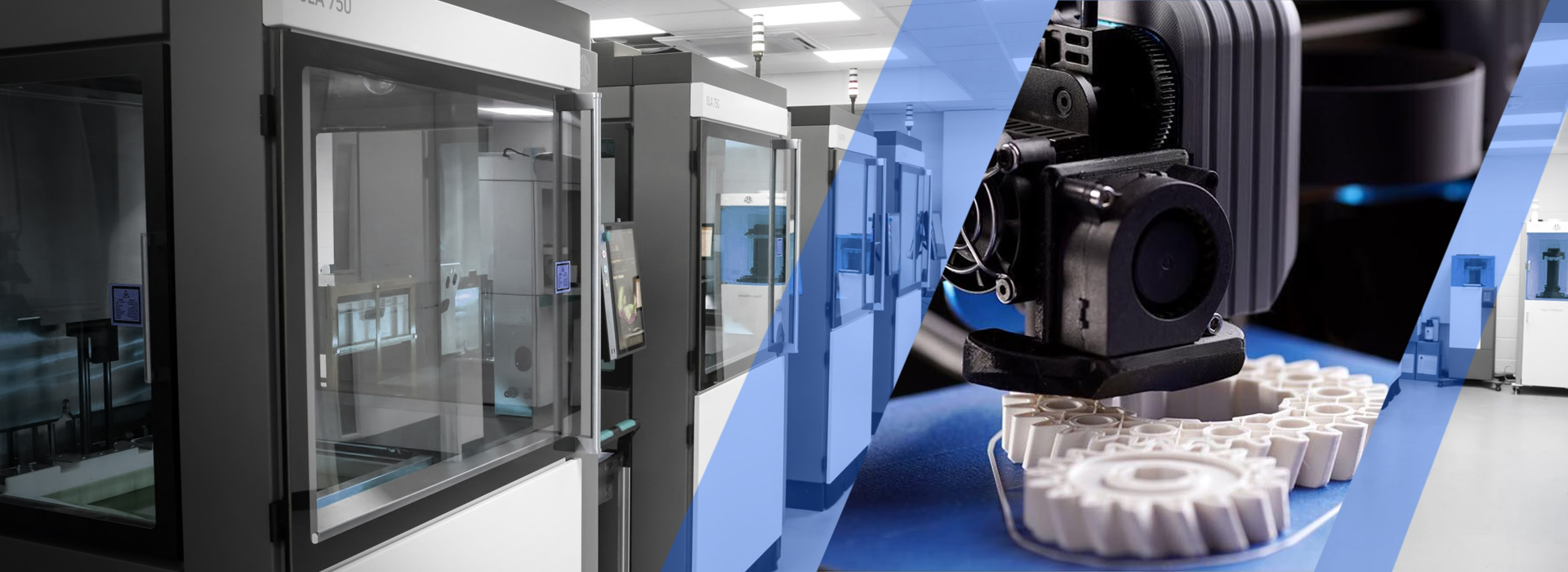

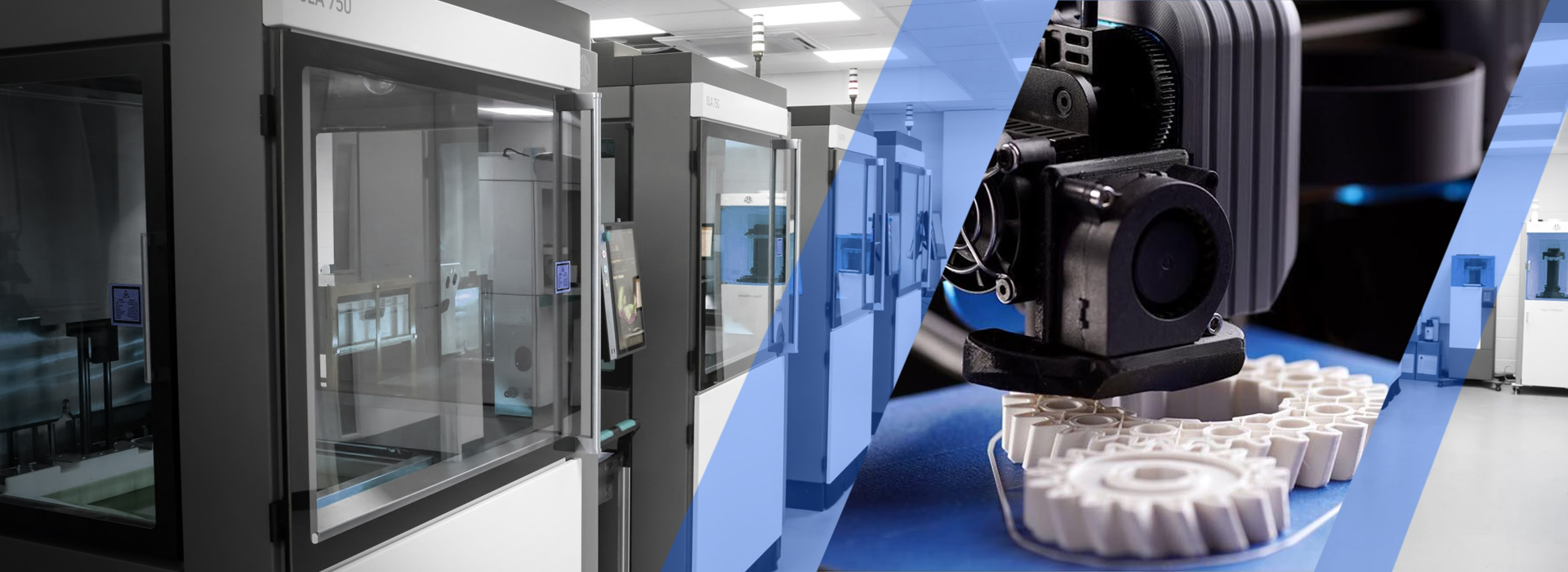

Leading Capabilities

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

24/7 Engineering Support

24/7 Engineering Support

TOP Prototype has a team of experienced engineers to provide auxiliary advice for your project, helping you optimize your design, save costs, and achieve better and more consistent quality standards through standardization.

15 +

15 + Years in Business

What is rapid prototyping plastic?

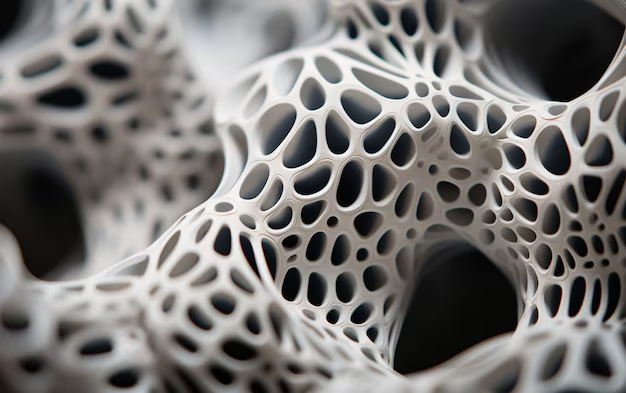

Rapid prototyping plastic refers to materials specifically designed for creating prototypes quickly using additive manufacturing technologies, such as 3D printing. These plastics can mimic the properties of final products and allow for quick iterations in design.

What are the advantages of using rapid prototyping plastic?

The advantages include reduced lead times for product development, lower costs compared to traditional manufacturing methods, the ability to easily modify designs, and the capacity to produce complex geometries that would be difficult to achieve otherwise.

What types of plastics are commonly used in rapid prototyping?

Common plastics used in rapid prototyping include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and nylon, each offering different properties suitable for various applications.

How does rapid prototyping with plastic impact product development?

Rapid prototyping with plastic accelerates product development by allowing designers and engineers to quickly test and validate concepts, gather feedback, and make necessary adjustments before final production, ultimately leading to faster time-to-market.

Learn More About Rapid Prototyping Plastic With Top Prototype!

TOP Prototype combines expertise in rapid prototyping plastic with practical solutions, empowering you to navigate this exciting field.

Bearing type: Characteristics and applications

Bearing type: Characteristics and applications If we break down rotating mechanical devices, systems or mechanisms, the different movements of their components are essential to their function. For example, blades rotate around the hub of a wind turbine to generate electricity. Do you know which devices or components control and indicate the desired movement within a

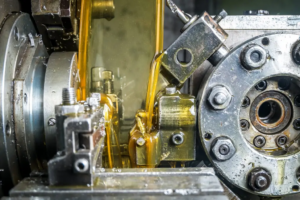

TOP Prototype CNC Drilling: Precision and Efficiency in Modern Manufacturing

TOP Prototype CNC Drilling: Precision and Efficiency in Modern Manufacturing In the realm of modern manufacturing, Computer Numerical Control (CNC) drilling has emerged as a crucial process that combines precision, speed, and versatility. This advanced machining technique plays a vital role in various industries, from aerospace and automotive to electronics and medical devices. In

Metal Surface Treatment: Processes and Significance

Metal Surface Treatment: Processes and Significance Metal surface treatment is a crucial aspect in the manufacturing and engineering fields. It involves various techniques that modify the surface properties of metals to enhance their performance, durability, and aesthetic appeal. Common Metal Surface Treatment Processes: Anodizing Anodizing is widely used, especially for aluminum. In this process,

TOP Prototype CNC Machining of Composite Materials

TOP Prototype CNC Machining of Composite Materials Composite materials have emerged as a crucial part of modern manufacturing due to their exceptional properties. TOP Prototype‘s expertise in CNC machining of these materials allows for the creation of precise and complex components with high performance. Let’s explore some common composite materials and their characteristics, along with

Unraveling the Wonders of TOP Prototype Electroplating: Process, Applications, and Impact

Unraveling the Wonders of TOP Prototype Electroplating: Process, Applications, and Impact What is Electroplating? TOP Prototype is a company that may utilize electroplating in its operations. Electroplating is a process that uses an electric current to deposit a thin layer of metal onto another metal or other conductive surface. In electroplating carried out

What is die casting? Process, material, application, cost

What is die casting? Process, material, application, cost Die casting turns vision into reality, enabling the precise manufacture of complex metal components that are the backbone of today’s leading industries from automotive to electronics. At the heart of the process is the high-pressure injection of molten metal into elaborate molds, laying the foundation for innovation

More About Rapid Prototyping Plastic & Top Prototype

Your request is our command! You can contact us, and we will provide you a quotation up on receipt of the detailed needs. We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. The rapid prototyping plastic will supply to all over the world, such as West Asia, South Africa, Mexico, Eastern Europe, etc. With a rich history spanning decades, our factory earned a reputation for advanced technologies, delivering excellence. We are looking forward to cooperating with you and providing our best services for you, as well as our rapid prototyping plastic, Aerospace Manufacturing,SWISS LATHE PROCESSING. TOP Prototype has already had a lot of top factories and qualified technology teams in China, offering the best rapid prototyping plastic and services to worldwide customers. We make great efforts to achieve this win-win situation, precision defines our every move, we put you, the customer, first. We are committed to improving production quality and efficiency continually for your satisfaction we also accept Customized Products order, all products have passed professional certification.

Other Categories From Top Prototype

Why Choose Top Prototype Rapid Prototyping Plastic ?

Rapid prototyping in plastics is a cutting-edge process that enables designers and engineers to swiftly create physical models from digital prototypes using various additive manufacturing techniques. This method leverages technologies such as 3D printing, CNC machining, and injection molding to produce prototypes that can effectively validate design concepts, test functionality, and assess ergonomics. The use of thermoplastics, such as ABS, PLA, and nylon, allows for diverse mechanical properties and surface finishes, catering to specific application needs. As a result, rapid prototyping not only accelerates the product development cycle but also enhances innovation by facilitating iterative design and reducing time-to-market.

Reliability Of Rapid Prototyping Plastic

Ah, rapid prototyping with plastic – it’s like speed dating for your ideas! You throw a design out there, and voila, you’ve got a tangible prototype faster than you can say “What did I just create?” Reliability in this world means you can count on your model to hold up under scrutiny (and maybe a bit of stress-testing). Think of it as the trusty sidekick in your product development journey, always ready to jump in and save the day. Plus, with a variety of plastics to choose from, you can tailor your prototype to be as tough as a superhero or as flexible as your morning yoga routine. So, let’s embrace the rapid, the reliable, and the wonderfully plastic, shall we?

Rapid Prototyping Plastic Safety

- Welcome to the world of rapid prototyping plastic! Where safety meets speed in a delightful dance of creativity!

- Safety first, folks! Remember, while we’re concocting fabulous prototypes, we don’t want to turn into mad scientists—safety goggles are a must!

- Check those temperature settings! You wouldn’t want your prototype to feel hotter than a summer day in the Sahara!

- Handling heated plastics? Think of it like making a gourmet meal—stay focused, and maybe don’t stick your hand in the oven!

- And let’s not forget about ventilation! No one likes a fume party, except maybe party favors gone wrong!

Cost-Effectiveness From Top Prototype

- Rapid prototyping with plastic is like getting a first draft of your masterpiece—no one expects it to be perfect, but it sure beats starting with a block of marble!

- Cost-effectiveness is the name of the game—why spend a fortune on a final product when you can create a series of affordable prototypes that let you tweak, test, and repeat faster than a caffeinated rabbit?

- Using plastic means you’re not just saving pennies; you’re saving time—because no one likes waiting for a design to set in stone. The only thing that should be set in stone is your grandma’s garden gnome!

- And with digital designs easily transformed into 3D models, you’ll be churning out prototypes like a bakery during the holidays—except your “cookies” won’t crumble when you run them through quality checks!

8 thoughts on “Rapid Prototyping Plastic”

One of the smartest choices I made was picking this company as my supplier for rapid prototyping plastic. They’re super flexible and incredibly helpful!

Our customers are really enjoying this batch of rapid prototyping plastic, and they appreciate our friendly and attentive service!

I gave this rapid prototyping plastic a shot, and it’s super sensitive! You really have to experience its specific uses to appreciate it—definitely worth the praise!

After working together multiple times, we can confidently say that this company is reliable. They genuinely focus on practical solutions, tackle challenging issues head-on, and consistently deliver quality work—especially when it comes to rapid prototyping plastic!

The rapid prototyping plastic is great quality, we really enjoy it and will definitely buy it again next time!

We’re in a bit of a rush for our purchasing needs this time, and I’m thrilled to discover some top-notch rapid prototyping plastic that fits the bill perfectly!

I’m really happy with this collaboration, and I look forward to the chance to work together again in the future, especially with rapid prototyping plastic!

The company takes its responsibilities seriously and is dedicated to fulfilling all customer needs, which is why they have built a fantastic reputation for their rapid prototyping plastic products.

Comments are closed.