Micro Swiss Machining | More Profit, Less Effort – 50% More!

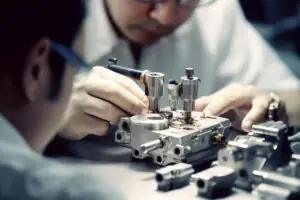

High-quality wholesale micro swiss machining from top prototype | chinese manufacturer top prototype, providing quality micro swiss machining , owning many yrs experience, offers the best micro swiss machining.

Introducing Our Top Prototype Category

High-quality wholesale micro swiss machining from top prototype | chinese manufacturer top prototype, providing quality micro swiss machining , owning many yrs experience, offers the best micro swiss machining.

Micro Swiss Machining From Top Prototype: Quality You Can Trust!

Discover Top-notch micro swiss machining at TOP Prototype. When it comes to micro swiss machining, TOP Prototype is a name you can rely on for their micro swiss machining.

Customer Review About Micro Swiss Machining: View Custom Reviews Now!

Our commitment to quality extends to customers worldwide through our satisfying micro swiss machining.

Interested In What Top Prototype Can Offer With Micro Swiss Machining? Contact Us Now!

Our production preferred stand out for their high quality, resilience, and user-friendly maintenance. Learn more by visiting our website.

Variety

Our services range from prototype design to large-scale production, from CNC lathes to milling centers, injection molding, advanced 3D printing equipment, etc.

60 +

60 + Countries Countries shipped

15 +

15 + Years in Business

What is micro Swiss machining?

Micro Swiss machining refers to a precision manufacturing process that involves the machining of small, intricate components with high accuracy, often used in industries like medical devices, aerospace, and electronics.

How does micro Swiss machining differ from traditional machining?

Micro Swiss machining focuses on producing very small parts with tight tolerances and complex geometries, while traditional machining may deal with larger components and less stringent precision requirements.

What materials are commonly used in micro Swiss machining?

Common materials include stainless steel, aluminum, titanium, and various plastics, chosen for their specific properties and suitability for micro-scale applications.

What industries benefit from micro Swiss machining?

Industries that benefit from micro Swiss machining include medical device manufacturing, aerospace, electronics, and precision engineering, where high precision and small parts are essential.

Discover More About Micro Swiss Machining From Top Prototype.

TOP Prototype is at the forefront of innovation, providing insights into micro swiss machining to help you stay informed.

CNC Machining of Aluminum: Properties and Applications by TOP Prototype

CNC Machining of Aluminum: Properties and Applications by TOP Prototype Aluminum, with its unique combination of physical and mechanical properties, has become a preferred material in CNC machining across various industries. As a professional prototype and custom part manufacturer,TOP Prototype leverages the advantages of aluminum in CNC machining to deliver high-precision, high-quality components for clients

TOP Pototype collaborates with Extremis: Outdoor Equipment Innovation

TOP Pototype collaborates with Extremis: Outdoor Equipment Innovation Wondering about CNC machining and why it’s so important in manufacturing? You’re not alone. Computer numerical control (CNC) machining is a key role in modern manufacturing, utilizing advanced technology to cut, shape and manufacture precision parts. This article details the working principle of CNC machine tools and

Notice on the 2024 Spring Festival holiday

Notice on the 2024 Spring Festival holiday Dear customer, As December approaches, Christmas cheer is in the air! Greetings, As December approaches, Christmas cheer is in the air! All of us at TOP Prototype are excited to send you our warmest holiday wishes. Looking ahead, the New Year and Chinese New Year are just around

Comprehensive guide for sheet metal edging: Techniques, uses and techniques

Sheet metal is widely used in the automotive and electronics industries. Over time, however, its sharp edges can become deformed and pose a safety risk. To solve this problem, the edges are often folded in a process called sheet metal flanging. This article explains what edging is, how it is done, the types of edging

Mastering CNC Milling: TOP Prototype’s Expertise in

Mastering CNC Milling: TOP Prototype’s Expertise in The Significance of CNC Milling in Modern Industry CNC milling stands as a cornerstone in the manufacturing landscape. It has revolutionized the way complex parts are fabricated. In this era of advanced technology, TOP Prototype has emerged as a key player in harnessing the full potential of CNC

More About Micro Swiss Machining & Top Prototype

We are looking forward to cooperating with you and providing our best services for you, as well as our micro swiss machining, Aerospace Manufacturing,SWISS LATHE PROCESSING. Our experienced R&D team is here to provide you with professional support, feel free to tell us your special requests or concerns, each product has been professionally certified to meet industry standards. Nowadays with the trend of internationalization, we’ve got decided to reach a broader audience. The micro swiss machining will supply to all over the world, such as West Asia, South Africa, Mexico, Eastern Europe, etc. Over the past few years, our factory absorbed and digested integrated advanced technologies, exceeding the industry standard. We’ve been honest and open up, high-quality is our life, trust builds our path to success. TOP Prototype has already had a lot of top factories and qualified technology teams in China, offering the best micro swiss machining and services to worldwide customers. We’ll satisfy you with our qualified service! If you are interested in any of our products, please feel free to contact us.

Other Categories From Top Prototype

Why Choose Top Prototype Micro Swiss Machining ?

Micro Swiss machining is an advanced manufacturing technique that focuses on creating very small and precise metal parts. This process uses specialized tools and machines to cut, shape, and finish materials at a micro scale. It is essential in industries like aerospace, medical devices, and electronics, where accuracy and detail are critical. The technology allows for high precision and the ability to produce intricate designs that would be difficult or impossible with traditional methods. As demand for smaller, more efficient components grows, micro Swiss machining is becoming increasingly important in modern manufacturing.

Environmental Impact Of Micro Swiss Machining

When it comes to micro Swiss machining, we’re not just talking precision; we’re talking about precision that’s got a green heart! These tiny parts may be minuscule, but their environmental impact doesn’t have to be. Imagine crafting intricate components with such finesse that they require less material and energy – it’s like transforming a lumberjack into a delicate artisan! With reduced waste and energy efficiency, micro machining is the eco-friendly superhero of manufacturing. So next time you see a small part, give it a nod – it’s saving the planet one micro-millimeter at a time!

Micro Swiss Machining Energy Efficiency

- Micro Swiss machining: where precision meets efficiency—think of it as the espresso shot of manufacturing!

- Energy efficient: these tiny titans use less juice to create minuscule masterpieces, saving both the planet and your wallet.

- Temperature temper: keep those tools cool—because nobody likes a heated argument in the workshop!

- Less waste, more haste: machining at a micro level means we’re slicing away waste like a ninja chef prepping sushi.

- Innovation on a dime: small changes lead to big results—like finding a dollar in your coat pocket after winter!

Reliability From Top Prototype

- Precision Like a Swiss Watch: Micro Swiss machining delivers precision that makes even a watchmaker nod in approval—tick, tick, perfection!

- Reliability That Doesn’t Fidget: Just like your friend who always arrives on time (and definitely does not forget their wallet), micro Swiss machining is consistently reliable in performance.

- Size Matters: In the micro world, tiny details mean big reliability—it’s all in the small print, literally!

- Temperature Control: Machining at the right temp keeps parts from throwing a tantrum like a toddler in a candy store—no overheating here!

- Durability Under Pressure: These micro parts can withstand pressure like a comedian in a tough crowd—no cracking under the heat!

8 thoughts on “Micro Swiss Machining”

It’s clear that the seller really knows their stuff when it comes to micro Swiss machining. Whenever we run into an issue, they take the time to explain things thoroughly, which makes us feel great!

This supplier guided us in selecting an excellent solution and helped us make smart purchasing choices based on our technical needs. We’re really happy with the outcome!

The company focuses on providing top-notch service and creating high-quality micro Swiss machining products, all while aiming to ensure that customers enjoy a fantastic shopping and collaboration experience.

If you’re not too familiar with micro swiss machining, I definitely suggest checking out this store. I’ve been taken for a ride by other places before because I didn’t quite get it, but the staff here are super helpful!

This micro Swiss machining from their lineup is great! I’ve checked out other stores, and their offerings really give you the best bang for your buck.

If you’re unsure about picking a supplier, go ahead and choose them for your Micro Swiss machining needs—you’ll be glad you did!

I’ve been using Micro Swiss Machining products for quite a while now, and I have to say, I’m really impressed! The quality is top-notch, and they’re definitely worth the investment.

Quality is the heartbeat of our enterprise, driving benefits and fueling growth. It’s all about teamwork—every one of us plays a part in ensuring that our Micro Swiss Machining products shine!

Comments are closed.