Laser Swiss Machining | Elevate Profit Margin: 25%

Laser swiss machining from the best manufacturer & wholesaler top prototype. search top prototype, who provides quality laser swiss machining. we devote to laser swiss machining market for several yrs.

Introducing Our Top Prototype Category

Laser swiss machining from the best manufacturer & wholesaler top prototype. search top prototype, who provides quality laser swiss machining. we devote to laser swiss machining market for several yrs.

Laser Swiss Machining – Top Prototype Offers Good Quality!

Invest in quality Top-notch laser swiss machining from TOP Prototype. If laser swiss machining are your priority, TOP Prototype offers reliable laser swiss machining to explore.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

See What People Are Saying About Laser Swiss Machining: Read Reviews!

Our commitment to quality extends to customers worldwide through our high-quality laser swiss machining.

Have Questions About Laser Swiss Machining? Contact Us For Answers!

The excellent we provide are characterized by their superb quality, long-lasting performance, and effortless upkeep. Check our website for more information.

Faster

When you complete the part design, share it with our company by email and synchronize your requirements.TOP Prototype adopts the most efficient quotation service and focuses on your product requirements.

Leading Capabilities

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

400,000 +

Uniquely designed parts produced 400,000 +

What is laser swiss machining?

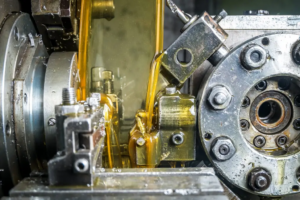

Laser swiss machining is a precision manufacturing process that combines the techniques of laser cutting and Swiss-style turning. It is used to create complex parts with high accuracy and fine tolerances, typically in small batch production.

How does laser swiss machining improve part accuracy?

Laser swiss machining improves part accuracy by using a laser to cut and shape materials with minimal thermal distortion and high precision, allowing for intricate designs and tight tolerances that are difficult to achieve with traditional machining methods.

What materials can be processed using laser swiss machining?

A wide variety of materials can be processed using laser swiss machining, including metals like stainless steel, aluminum, and titanium, as well as plastics and composites, making it versatile for different applications.

What industries commonly use laser swiss machining?

Industries that commonly use laser swiss machining include aerospace, medical device manufacturing, automotive, and electronics, where high precision and complex geometries are often required.

Curious About Laser Swiss Machining? Check What Top Prototype Has To Offer!

TOP Prototype combines expertise in laser swiss machining with practical solutions, empowering you to navigate this exciting field.

Key Advantages Propelling the Popularity of Injection Molding

Key Advantages Propelling the Popularity of Injection Molding Exceptional Precision and Dimensional Accuracy Injection molding, as practiced by TOP Prototype, offers an outstanding level of precision that is crucial in many industries. The molds used in the process are fabricated with utmost care and accuracy, often with tolerances in the micrometer range. This

CNC Machining Tolerance: Significance & Standard & Dependence

CNC prototype machining is all about precision. It produces parts with relative quality and relative dimensional accuracy. Relative to the process, one of the more integral components of it is CNC machining tolerances. It is the acceptable measurement of deviation in the dimension of a part. These tolerances indicate how exact a part is within

TOP Prototype 2023 Chinese New Year holiday Notice

Notice on the 2024 Spring Festival holiday Greetings, As December approaches, Christmas cheer is in the air! Greetings, As December approaches, Christmas cheer is in the air! All of us at TOP Prototype are excited to send you our warmest holiday wishes. Looking ahead, the New Year and Chinese New Year are just around the

What is die casting? Process, material, application, cost

What is die casting? Process, material, application, cost Die casting turns vision into reality, enabling the precise manufacture of complex metal components that are the backbone of today’s leading industries from automotive to electronics. At the heart of the process is the high-pressure injection of molten metal into elaborate molds, laying the foundation for innovation

High – Precision Sheet Metal Bending in TOP Prototype Company

High – Precision Sheet Metal Bending in TOP Prototype Company Ⅰ. Introduction In the modern manufacturing industry, sheet metal bending plays a crucial role in the production process. TOP Prototype, as a well – known company in this field, has extensive experience and advanced techniques in sheet metal bending operations. This paper will explore the

Case study :TOP Prototype and Tesla’s extraordinary wheel kit

Case study :TOP Prototype and Tesla’s extraordinary wheel kit Wondering about CNC machining and why it’s so important in manufacturing? You’re not alone. Computer numerical control (CNC) machining is a key role in modern manufacturing, utilizing advanced technology to cut, shape and manufacture precision parts. This article details the working principle of CNC machine tools

More About Laser Swiss Machining & Top Prototype

We strive provide the best quality products, with competitive prices, we champion innovation and integrity, customer first’ is our motto. We are looking forward to cooperating with you and providing our best services for you, as well as our laser swiss machining, Aerospace Manufacturing,SWISS LATHE PROCESSING. The consumer fulfillment is our primary goal. We sincerely welcome you to consult for your long-term cooperation as well as the mutual advancement. TOP Prototype collaborates with many factories and qualitified team to provide expert and affordable laser swiss machining to global customers. We welcome new and previous clients from all walks of lifestyle to get in touch with us for long term business relationships and mutual accomplishment! The world is our market – this laser swiss machining will be supplied globally to West Asia, South Africa, Canada, Eastern Europe, etc. To ensure your satisfaction, we contine to enhance production quality and effeciency, we welcome all custom orders, we ensure that every product meets the criteria for professional certification. Over the past few years, our factory absorbed and digested integrated advanced technologies, exceeding the industry standard.

Other Categories From Top Prototype

Why Choose Top Prototype Laser Swiss Machining ?

Laser Swiss machining is a cutting-edge manufacturing process that combines the precision of laser technology with the efficiency of Swiss-style machining. This technique excels in producing intricate parts with tight tolerances, making it ideal for industries such as medical devices, aerospace, and electronics. The process involves using a high-powered laser to cut and shape materials while a Swiss CNC lathe simultaneously performs complex operations, ensuring superior accuracy and minimized waste. As the demand for rapid prototyping and custom components grows, laser Swiss machining stands out as a vital solution, blending tradition with modern innovation to meet the needs of evolving markets.

Precision Of Laser Swiss Machining

Laser Swiss machining is a cutting-edge manufacturing technique renowned for its precision and efficiency in producing intricate components. By utilizing advanced laser technology alongside Swiss-style machining, this method ensures tight tolerances and high-quality finishes, making it a popular choice in industries requiring detailed and complex parts, such as aerospace and medical applications. Its ability to handle a variety of materials with minimal thermal distortion further enhances its appeal, positioning it as an essential tool in the landscape of rapid prototyping.

Laser Swiss Machining Unique Features

- Precision Engineering: Laser Swiss machining combines laser technology with traditional Swiss machining for unparalleled accuracy.

- Complex Geometries: Capable of producing intricate shapes and features that are difficult to achieve with conventional methods.

- Material Versatility: Suitable for a wide range of materials including metals, plastics, and composites.

- Enhanced Surface Finish: Provides superior surface quality with minimal post-processing required.

- High Efficiency: Faster production rates due to the combination of laser cutting and turning capabilities.

- Minimal Waste: Optimizes material usage, reducing scrap and enhancing sustainability.

- Flexibility: Easily adapts to both low and high volume production runs.

Energy Efficiency From Top Prototype

- Energy Efficiency: Laser Swiss machining utilizes laser technology that consumes less energy compared to traditional methods, resulting in lower operational costs and minimal environmental impact.

- Precision: The process ensures high precision and accuracy, reducing material waste and enhancing the overall efficiency of production.

- Versatility: Capable of working with a wide range of materials, including metals and plastics, making it suitable for diverse applications in various industries.

- Reduced Cycle Time: Rapid prototyping capabilities allow for quicker turnaround times, facilitating faster product development and market entry.

- Popular Choice: Increasingly favored for its ability to produce intricate designs and complex geometries that traditional machining may struggle with.

6 thoughts on “Laser Swiss Machining”

Our company should be among the pioneers in forming a long-term partnership with this firm. The results have shown that we made the right decision. In recent years, the advantages of our laser Swiss machining products have been evident!

After years of working in the field, they’ve gained a wealth of industry experience and a solid grasp of customer needs, always staying true to their capabilities. This partnership turned out to be a great success!

Its visuals are clear and vibrant, especially impressive at night. The price is quite reasonable, making it a great choice to get started with laser Swiss machining!

The laser Swiss machining showed up the very next day, and setting it up was a breeze!

Your laser Swiss machining is top-notch and always arrives right on schedule!

This supplier is fantastic! I’ll definitely reach out to you again for collaboration whenever I have more demand for laser Swiss machining.

Comments are closed.