Injection Molding Services | More Profit, Less Effort – 55% More!

Discover injection molding services from top prototype – quality and style combined! top prototype, providing innovative injection molding services , owning many yrs experience, offers the best injection molding services.

Introducing Our Top Prototype Category

Discover injection molding services from top prototype – quality and style combined! top prototype, providing innovative injection molding services , owning many yrs experience, offers the best injection molding services.

Injection Molding Services – Invest In Quality With Top Prototype!

Get your hands on TOP Prototype’s Innovative injection molding services. TOP Prototype stands out for the injection molding services, perfect for your injection molding services needs.

See What People Are Saying About Injection Molding Services: Read Reviews!

Our high-quality injection molding services have found their way to customers across the planet.

Curious About Injection Molding Services? Don’T Hesitate To Reach Out!

The trustworthy we provide are characterized by their superb quality, long-lasting performance, and effortless upkeep. Check our website for more information.

Faster

When you complete the part design, share it with our company by email and synchronize your requirements.TOP Prototype adopts the most efficient quotation service and focuses on your product requirements.

More Responsive Quotes

We will give you feedback within 1 hour to ensure that you receive professional processing suggestions, lower processing costs and a faster delivery time.

Leading Capabilities

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

What is injection molding services?

Injection molding services refer to a manufacturing process used to produce parts by injecting molten material into a mold. This process is commonly used for plastics, metals, and glass to create precise and complex shapes efficiently.

What materials are commonly used in injection molding?

The most common materials used in injection molding include thermoplastics such as ABS, polycarbonate, and polypropylene, as well as thermosetting plastics and certain metals. Each material offers different properties suited for various applications.

What are the advantages of using injection molding services?

The advantages of injection molding services include high production efficiency, the ability to create intricate designs, reduced waste, and consistency in product quality. It also allows for rapid scaling of production volumes.

How can I choose the right injection molding service provider?

To choose the right injection molding service provider, consider factors such as their experience, technology capabilities, quality assurance processes, lead times, customer reviews, and cost competitiveness. It’s also beneficial to request samples of their previous work.

Want To Know More About Injection Molding Services?

TOP Prototype is at the forefront of innovation, providing insights into injection molding services to help you stay informed.

TOP Prototype 2023 Chinese New Year holiday Notice

Notice on the 2024 Spring Festival holiday Greetings, As December approaches, Christmas cheer is in the air! Greetings, As December approaches, Christmas cheer is in the air! All of us at TOP Prototype are excited to send you our warmest holiday wishes. Looking ahead, the New Year and Chinese New Year are just around the

What is wire cutting? Process and application description

What is wire cutting? Process and application description Lathes and milling machines are often associated with machining, but line discharge machining (EDM) offers special advantages for certain applications. Wire-cut machining is an electrothermal process that uses electrical discharges to shape conductive materials so that complex designs can be created. The technology is widely used in

Sheet Metal Cutting Processes: An In – depth Analysis

Sheet Metal Cutting Processes: An In – depth Analysis

Black Oxide: A Versatile Surface Treatment

Black Oxide: A Versatile Surface Treatment Introduction Surface treatment plays a crucial role in enhancing the properties and appearance of various materials. One such method is black oxide, which has gained popularity in numerous industries. This article will explore the definition, working principle, technical knowledge, advantages, and industry applications of black oxide, with references to

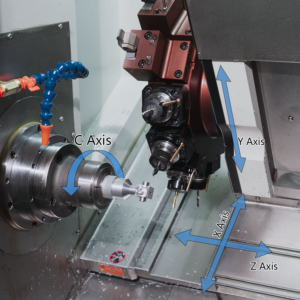

TOP Prototype CNC Machining of Metal Materials

TOP Prototype CNC Machining of Metal Materials CNC machining plays a crucial role in the manufacturing industry, especially when it comes to processing various metal materials. At TOP Prototype, we understand that different metal materials have their own unique characteristics and require specific machining considerations. Our expertise in CNC machining allows us to handle

Key Advantages Propelling the Popularity of Injection Molding

Key Advantages Propelling the Popularity of Injection Molding Exceptional Precision and Dimensional Accuracy Injection molding, as practiced by TOP Prototype, offers an outstanding level of precision that is crucial in many industries. The molds used in the process are fabricated with utmost care and accuracy, often with tolerances in the micrometer range. This

More About Injection Molding Services & Top Prototype

We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. Our injection molding services will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc. As a reliable and professional company, TOP Prototype partners with skilled tech teams and offers the best solutions as well as injection molding services to global customers. While in the past few years, our factory absorbed and digested integrated advanced technologies, defining our professional approach. We are looking forward to cooperating with you and providing our best services for you, as well as our injection molding services, 3D PRINTING,5-AXIS CNC MACHINING. We are committed to improving production quality and efficiency continually for your satisfaction we also accept Customized Products order, all products have passed professional certification. Many clients came to visit our factory and place orders. Don’t hesitate to contact for a free quote and further information! We believe in: precision defines our every move, trust paves our way to success.

Other Categories From Top Prototype

Why Choose Top Prototype Injection Molding Services ?

Injection molding is a highly efficient manufacturing process that allows businesses to create complex plastic parts with precision and speed. This technique involves injecting molten plastic into a custom-designed mold, where it cools and solidifies into the final product. Our injection molding services are designed to meet the unique needs of regional clients, offering tailored solutions that streamline production and minimize costs. With a commitment to quality and rapid prototyping, we ensure that your concepts are transformed into tangible components quickly and effectively, allowing you to stay ahead in today’s competitive market.

Ease Of Construction Of Injection Molding Services

Injection molding services offer a streamlined approach to manufacturing complex plastic parts with high precision and efficiency. This process involves injecting molten material into a mold cavity, allowing for intricate designs and rapid production cycles. The ease of construction associated with injection molding lies in its ability to replicate detailed geometries consistently, accommodating both large-scale production and prototyping needs. Furthermore, the scalability of injection molding ensures that products can be efficiently transitioned from prototype to full production, making it an ideal choice for industries seeking quick turnaround times without compromising on quality.

Injection Molding Services Safety

- Safety Compliance: Adherence to industry safety standards to ensure a secure production environment.

- Material Integrity: Utilization of high-quality, safety-tested materials to prevent hazardous reactions and ensure product reliability.

- Process Control: Rigorous monitoring of temperature and pressure during injection molding to minimize risks of defects and accidents.

- Operator Training: Comprehensive training programs for operators to enhance safety awareness and operational efficiency.

- Maintenance Protocols: Regular maintenance checks on machinery to ensure safe and smooth operation without unexpected failures.

- Emergency Preparedness: Implementation of robust emergency response plans to swiftly address any incidents that may arise during production.

Durability From Top Prototype

- Durability: Injection molding produces robust components that can withstand rigorous use and environmental stressors.

- Material Versatility: A wide range of materials, including reinforced plastics and thermoplastics, offer enhanced strength and longevity.

- Precision Engineering: High accuracy in mold design ensures consistent quality and performance across large production runs.

- Cost-Effectiveness: Economies of scale achieved through efficient production reduce overall costs while maintaining durability.

- Minimal Waste: The process optimizes material usage, contributing to sustainability without compromising on quality.

3 thoughts on “Injection Molding Services”

This company really knows their stuff! Before we made our purchase, there were quite a few things we were unsure about. Their customer service was super patient in answering all our questions, which made me feel great.

What really stands out to me is how dedicated and attentive our customers are. They always respond to our questions and concerns with such patience, and they express their gratitude after receiving our injection molding services.

Even though I didn’t order a lot this time, the package was really well put together. I’m happy with the quality of all the injection molding services I received. I’ll definitely come back when I need more!

Comments are closed.