Injection Molding Rapid Prototyping | Boosting Profit: 50%

Top wholesale injection molding rapid prototyping from top prototype | free samples top prototype provides trustworthy injection molding rapid prototyping ,& owns a long experience, providing top injection molding rapid prototyping.

Check Out Our Top Prototype Category

Top wholesale injection molding rapid prototyping from top prototype | free samples top prototype provides trustworthy injection molding rapid prototyping ,& owns a long experience, providing top injection molding rapid prototyping.

Injection Molding Rapid Prototyping – Elevate Your Business With Quality!

Don’t miss out on TOP Prototype’s exclusive Premium injection molding rapid prototyping. TOP Prototype is a well-regarded partner with injection molding rapid prototyping. You can rely on them for injection molding rapid prototyping.

Read What Customers Are Saying About Injection Molding Rapid Prototyping!

Our top-quality injection molding rapid prototyping are in demand among customers from around the world.

Interested In Injection Molding Rapid Prototyping? Contact Us Now!

Our trustworthy, expect nothing less than premium quality, long-term durability, and straightforward maintenance. Find out more on our website.

Faster

When you complete the part design, share it with our company by email and synchronize your requirements.TOP Prototype adopts the most efficient quotation service and focuses on your product requirements.

Leading Capabilities

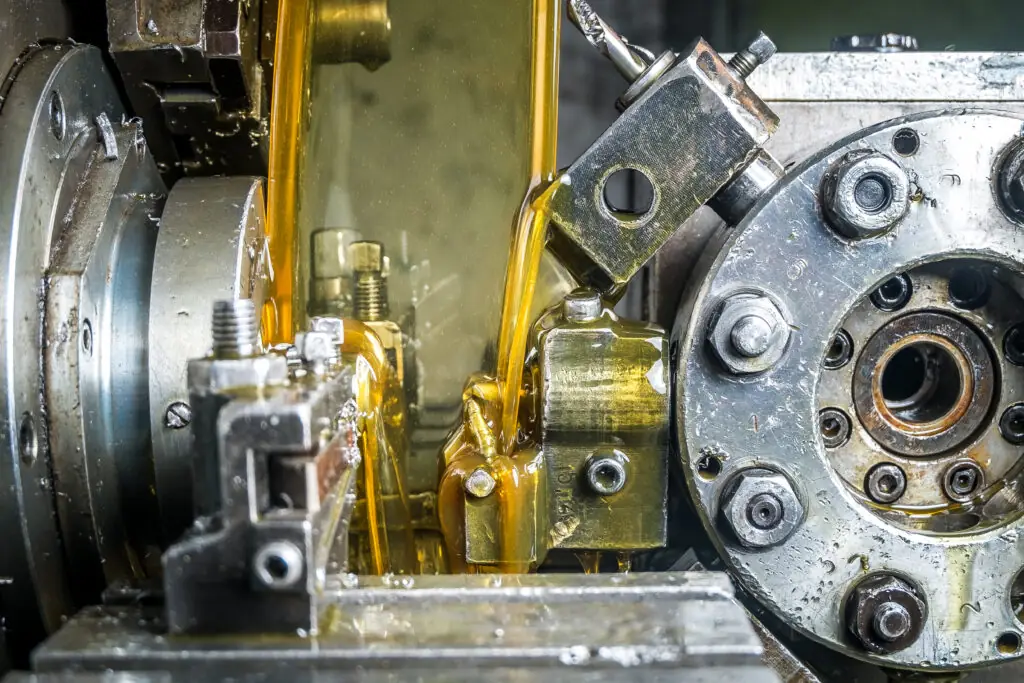

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

Variety

Our services range from prototype design to large-scale production, from CNC lathes to milling centers, injection molding, advanced 3D printing equipment, etc.

What is injection molding rapid prototyping?

Injection molding rapid prototyping is a manufacturing process that allows for the quick production of plastic parts using injection molding techniques. It involves creating a mold for producing small quantities of parts, enabling designers to test and iterate their designs quickly.

What are the benefits of using injection molding for rapid prototyping?

The benefits include high precision, repeatability, and the ability to produce complex geometries. Additionally, it allows for the production of parts with the same materials and properties as those used in final production.

How does injection molding rapid prototyping differ from traditional prototyping methods?

Injection molding rapid prototyping differs in that it uses a mold to produce parts, allowing for faster production of functional prototypes that closely mimic final products, whereas traditional methods like 3D printing may not achieve the same material properties or dimensions.

What industries commonly utilize injection molding rapid prototyping?

Industries such as automotive, aerospace, consumer products, and medical devices commonly utilize injection molding rapid prototyping to quickly develop and test new designs before full-scale production.

Discover More About Injection Molding Rapid Prototyping From Top Prototype.

Explore how TOP Prototype enhances your understanding of injection molding rapid prototyping through cutting-edge solutions and expert knowledge.

CNC Programming: Concepts and Commonly Used Languages

CNC Programming: Concepts and Commonly Used Languages Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry, enabling the production of highly precise and complex parts with ease. At the heart of CNC machining lies programming, which dictates the movements and operations of the machine tools. In this article, we will explore the basic concepts

The Excellence of Spraying Surface Treatment

The Excellence of Spraying Surface Treatment Surface treatment is a crucial aspect of modern manufacturing and product enhancement, and spraying is one of the most commonly used and effective methods. This article will delve into the details of spraying, including its definition, working principle, technical knowledge, advantages, and its connection with the TOP Prototype company.

Step into the World of TOP Prototype CNC Machined Delights: A Visual Feast

Step into the World of TOP Prototype CNC Machined Delights: A Visual Feast CNC machining has emerged as a revolutionary force, creating a world of precision-engineered wonders that tantalize the eyes and captivate the imagination. TOP Prototype, a renowned name in the industry, has been a key player in this exciting landscape. TOP Prototype’s

The Power of TOP Prototype Powder Coating

The Power of TOP Prototype Powder Coating Powder coating by TOP Prototype is a revolutionary finishing process that has gained significant popularity in various industries due to its numerous advantages and unique characteristics. In this article, we will explore the concept, working principle, history, and advantages of powder coating offered by TOP Prototype. I. Concept

An Exhaustive Exploration of Working Principles, Machine Components, and Production Benefits

An Exhaustive Exploration of Working Principles, Machine Components, and Production Benefits CAD – CAM refers to the software used for designing and machining parts and components with a CNC machine. TOP Prototype utilizes this advanced technology. CAD (Computer – Aided Design) software is used to design, draw, and shape parts using geometric shapes and constructs

The Significance of CNC Machined Parts in the Automotive Field by TOP Prototype

The Significance of CNC Machined Parts in the Automotive Field by TOP Prototype In the highly competitive automotive industry, the pursuit of precision, quality, and innovation is unending. One of the key elements that has significantly contributed to the advancement of automotive manufacturing is the use of CNC machined parts. TOP Prototype, a renowned

More About Injection Molding Rapid Prototyping & Top Prototype

As a reliable and professional company, TOP Prototype partners with skilled tech teams and offers the best solutions as well as injection molding rapid prototyping to global customers. While in the past few years, our factory absorbed and digested integrated advanced technologies, defining our professional approach. We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. Our injection molding rapid prototyping will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc. We believe we will have good cooperative relationships and make a brilliant future for both parties. Seeing is Believing, want far more info? Give us a chance, give you a surprise. We strive provide the best quality products, with competitive prices, we champion innovation and integrity, customer first’ is our motto. We are looking forward to cooperating with you and providing our best services for you, as well as our injection molding rapid prototyping, Aerospace Manufacturing,5-AXIS CNC MACHINING. To ensure your satisfaction, we contine to enhance production quality and effeciency, we welcome all custom orders, we ensure that every product meets the criteria for professional certification.

Other Categories From Top Prototype

Why Choose Top Prototype Injection Molding Rapid Prototyping ?

Injection molding rapid prototyping stands as a pivotal technique in the intersection of design and manufacturing, enabling the swift creation of complex geometries with unparalleled precision. This methodology harnesses the power of thermoplastics, which upon heating, can be effortlessly injected into meticulously crafted molds, yielding prototypes that mirror the final product’s dimensional accuracy and surface finesse. The versatility inherent in this process allows for the exploration of various material properties and design iterations in a fraction of the time traditionally required. As industries continue to demand accelerated development cycles and innovative solutions, injection molding emerges not merely as a production method, but as a catalyst for creativity and efficiency in product development.

Aesthetics Of Injection Molding Rapid Prototyping

Injection molding rapid prototyping is a pivotal technique in the realm of product development, enabling designers to create high-fidelity prototypes that closely mimic the final product in both form and function. This method not only accelerates the design process but also enhances aesthetic qualities, allowing for smooth surfaces, intricate details, and precise colors that appeal to global markets. By leveraging advanced materials and technologies, businesses can swiftly iterate on designs, ensuring that the prototypes resonate with international standards of quality and allure. As a result, injection molding rapid prototyping fosters innovation while maintaining a keen eye on aesthetic excellence.

Injection Molding Rapid Prototyping Reliability

- Reliability: Injection molding rapid prototyping ensures consistent quality and precision, minimizing defects and enhancing product reliability.

- Speed: This process allows for faster turnaround times, enabling quicker iterations for design validation and market entry.

- Cost-Effectiveness: Reduces costs associated with traditional prototyping methods by utilizing fewer resources and materials.

- Material Variety: Supports a wide range of materials, allowing for versatile applications and the ability to test different properties.

- Scalability: Easily scales from prototypes to full-scale production, facilitating seamless transitions in development stages.

- International Standards: Adheres to global quality standards, ensuring products meet international regulatory requirements.

Precision From Top Prototype

- Precision: Injection molding offers high dimensional accuracy, crucial for parts with tight tolerances.

- Speed: Rapid prototyping through injection molding can produce functional parts quickly, reducing time to market.

- Material Variety: A wide range of thermoplastics and elastomers can be used, enabling diverse applications.

- Cost-Effectiveness: Once a mold is created, the cost per unit decreases significantly with high-volume production.

- International Standards: Meets global manufacturing standards, ensuring quality and consistency across markets.

- Iterative Testing: Facilitates rapid design iterations and real-world testing, enhancing product development cycles.

4 thoughts on “Injection Molding Rapid Prototyping”

After a great collaboration, we’re thrilled to have discovered a company with outstanding productivity. They’ve earned our trust through their impressive expertise in injection molding rapid prototyping!

Taking into account what users want and their experiences, this company has created a unique line of injection molding rapid prototyping products. These items are available in many countries and regions both in China and abroad.

After years of working together, we’ve seen some exciting new developments in injection molding rapid prototyping. We’re really happy to have partnered with such an innovative and responsible manufacturer!

The service here is fantastic, and they really nail the injection molding rapid prototyping! I’ll definitely be back next time.

Comments are closed.