Die Casting Solutions | Dynamic China Manufacturer 2024

Discover die casting solutions from top prototype – quality and style combined! search top prototype, who provides innovative die casting solutions. we devote to die casting solutions market for several yrs.

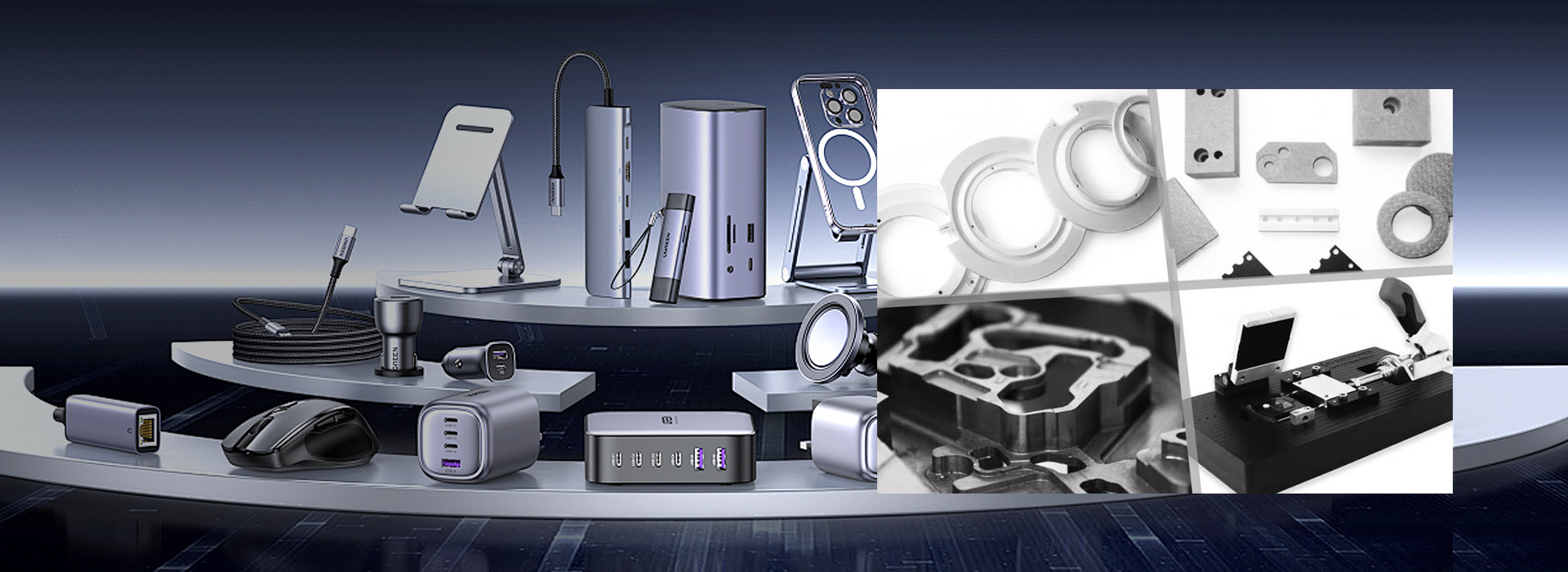

Introducing Our Top Prototype Category

Discover die casting solutions from top prototype – quality and style combined! search top prototype, who provides innovative die casting solutions. we devote to die casting solutions market for several yrs.

Die Casting Solutions – Elevate Your Business With Quality!

Discover Innovative die casting solutions at TOP Prototype. If die casting solutions are your priority, TOP Prototype offers reliable die casting solutions to explore.

Explore Customer Reviews For Die Casting Solutions: Check Them Out!

Our great value for money die casting solutions are sought after by customers worldwide.

Want To Explore Die Casting Solutions Further? Reach Out Today!

You can expect our not to be missed to be top-quality, long-lasting, and straightforward to maintain. Learn more by visiting our website.

400,000 +

Uniquely designed parts produced 400,000 +

60 +

60 + Countries Countries shipped

15 +

15 + Years in Business

What is die casting and how does it work?

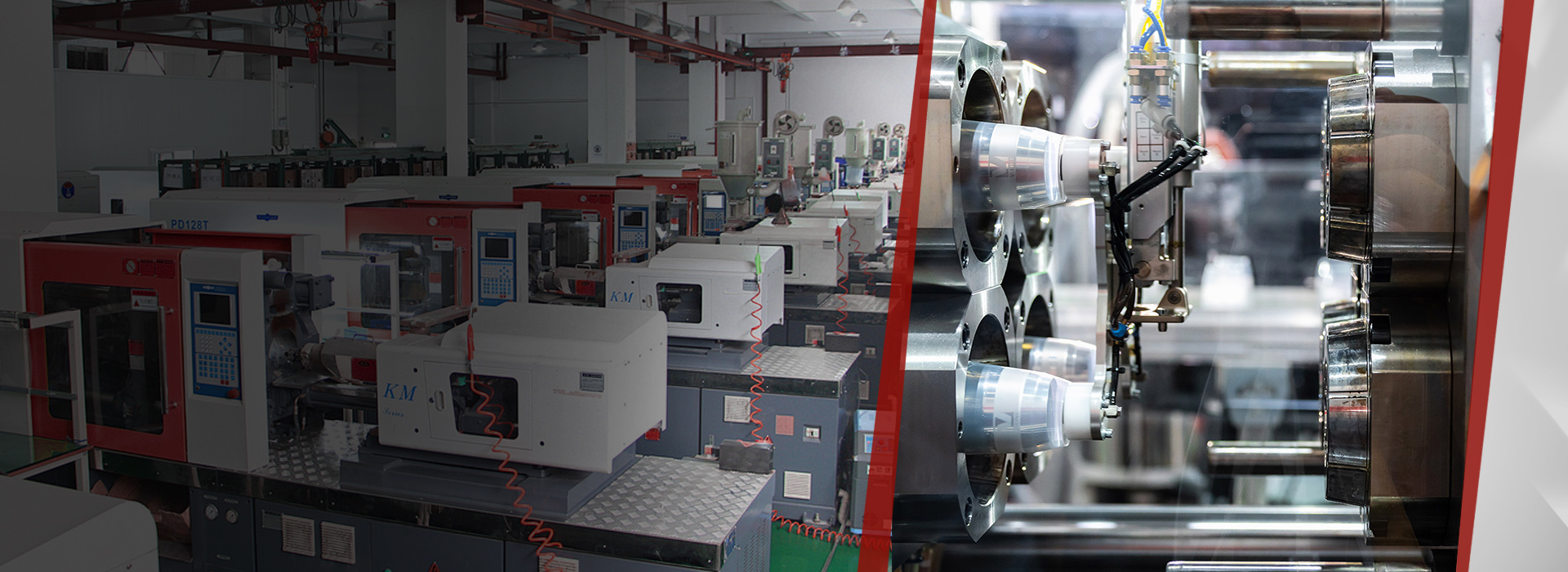

Die casting is a manufacturing process that involves forcing molten metal into a mold under high pressure. The process results in precise and intricate shapes with a smooth surface finish, ideal for mass production of metal parts.

What are the advantages of using die casting solutions?

Die casting solutions offer several advantages, including high dimensional accuracy, excellent surface finish, reduced machining costs, and the ability to produce complex shapes quickly and efficiently.

What materials are commonly used in die casting?

Common materials used in die casting include aluminum, zinc, magnesium, and copper alloys. Each material has unique properties that make it suitable for different applications.

How can businesses choose the right die casting solution for their needs?

Businesses can choose the right die casting solution by considering factors such as the desired material, production volume, complexity of the part, and cost constraints. Consulting with a die casting expert can also provide valuable insights tailored to specific requirements.

Want To Know More About Die Casting Solutions?

With a focus on die casting solutions, TOP Prototype offers comprehensive resources to deepen your understanding and application.

Unraveling the Wonders of TOP Prototype Electroplating: Process, Applications, and Impact

Unraveling the Wonders of TOP Prototype Electroplating: Process, Applications, and Impact What is Electroplating? TOP Prototype is a company that may utilize electroplating in its operations. Electroplating is a process that uses an electric current to deposit a thin layer of metal onto another metal or other conductive surface. In electroplating carried out

CNC Machining Tolerance: Significance & Standard & Dependence

CNC prototype machining is all about precision. It produces parts with relative quality and relative dimensional accuracy. Relative to the process, one of the more integral components of it is CNC machining tolerances. It is the acceptable measurement of deviation in the dimension of a part. These tolerances indicate how exact a part is within

Bearing type: Characteristics and applications

Bearing type: Characteristics and applications If we break down rotating mechanical devices, systems or mechanisms, the different movements of their components are essential to their function. For example, blades rotate around the hub of a wind turbine to generate electricity. Do you know which devices or components control and indicate the desired movement within a

All You Need to Know about SLA Manufacturing in the Medical Industry

In the world of 3D printing, SLA manufacturing holds a special place, especially in industries where extreme precision and fine detail are critical. One specific field is the medical industry, where precise, tailored, and biocompatible components may have a life-changing impact. Among the numerous additive manufacturing methods, SLA manufacturing has become a preferred method for

CNC Programming: Concepts and Commonly Used Languages

CNC Programming: Concepts and Commonly Used Languages Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry, enabling the production of highly precise and complex parts with ease. At the heart of CNC machining lies programming, which dictates the movements and operations of the machine tools. In this article, we will explore the basic concepts

High – Precision Sheet Metal Bending in TOP Prototype Company

High – Precision Sheet Metal Bending in TOP Prototype Company Ⅰ. Introduction In the modern manufacturing industry, sheet metal bending plays a crucial role in the production process. TOP Prototype, as a well – known company in this field, has extensive experience and advanced techniques in sheet metal bending operations. This paper will explore the

More About Die Casting Solutions & Top Prototype

We hunt forward towards your coming, dedication to high-quality is our life, customer first’ is our motto. TOP Prototype is dedicated into the market to providing premium die casting solutions and service worldwide. Let us cooperate hand in hand to make a good future. Don’t hesitate to contact for a free quote and further information! Nowadays with the trend of internationalization, we’ve got decided to reach a broader audience. We supply our die casting solutions worldwide, with markets including Southeast Asia, West Africa, Mexico, Western Europe, etc. Our advanced production facilities ensure high-qualiy products, we accept and consider all orders with unique specifications, we ensure that every product meets the criteria for professional certification. We are looking forward to cooperating with you and providing our best services for you, as well as our die casting solutions, Aerospace Manufacturing,SWISS LATHE PROCESSING. With a rich history spanning decades, our factory earned a reputation for advanced technologies, delivering excellence.

Other Categories From Top Prototype

Why Choose Top Prototype Die Casting Solutions ?

Die casting solutions are revolutionizing the way we manufacture components with precision and speed! Imagine a world where intricate designs come to life in a matter of moments, where high-quality metal parts are produced with unmatched efficiency. That’s the magic of die casting! This innovative process involves forcing molten metal into a mold under high pressure, resulting in stunningly accurate and consistent parts. Whether it’s automotive, aerospace, or consumer products, die casting is transforming industries with its ability to produce complex shapes and lightweight designs. Get ready to embrace a future where die casting leads the charge in rapid prototyping and advanced manufacturing solutions!

Environmental Impact Of Die Casting Solutions

Die casting solutions have emerged as a vital player in the quest for sustainable manufacturing practices, balancing efficiency with environmental responsibility. This process, known for its precision and speed, significantly reduces waste compared to traditional metalworking techniques, thereby minimizing its ecological footprint. Moreover, advances in die casting technology allow for the use of recyclable materials and eco-friendly alloys, further enhancing its sustainability profile. As global industries increasingly embrace green initiatives, die casting serves as a bridge between high-performance manufacturing and environmental stewardship, setting a new standard for international practices.

Die Casting Solutions Durability

- Durability: Die casting provides robust and durable components capable of withstanding harsh environments and high-stress applications.

- Temperature Resistance: Suitable for high-temperature operations, die cast components maintain structural integrity and performance under thermal stress.

- Precision Manufacturing: Offers high dimensional accuracy and complex geometries, reducing the need for additional machining.

- Material Versatility: Compatible with various alloys, including aluminum, zinc, and magnesium, ensuring tailored solutions for diverse applications.

- Cost Efficiency: Optimizes production costs through reduced waste and faster cycle times, making it an economical choice for high-volume production.

- International Standards: Adheres to global quality and safety standards, ensuring reliability and consistency across international markets.

Precision From Top Prototype

- Precision Engineering: Die casting offers high dimensional accuracy, ensuring that components meet stringent specifications and fit perfectly in assemblies.

- International Standards: Adheres to global quality standards, making it a reliable choice for industries worldwide.

- Rapid Production: Facilitates quick turnaround times for prototypes and mass production, speeding up the time to market.

- Material Versatility: Compatible with a variety of metals, including aluminum, zinc, and magnesium, catering to diverse application needs.

- Cost-Effective: Reduces waste and lowers manufacturing costs, providing an economical solution for large-scale production.

8 thoughts on “Die Casting Solutions”

The die casting solutions are top-notch, with excellent craftsmanship and no signs of poor quality. Our leaders are really pleased with them!

Their after-sales service team is super professional, friendly, and really skilled. They even follow up with phone calls! Overall, the service is excellent. I’ll definitely keep this supplier in mind for die casting solutions!

This supplier offers a great range of die casting solutions at really affordable prices. Plus, their customer service team is friendly and knows their stuff!

This company really knows their stuff! Before we made our purchase, there were plenty of things we didn’t quite get. Their customer service was super patient in answering all our questions, which made me feel great about the whole process.

Our boss is really pleased with how professional your team is, and it’s great to see you all smiling while providing excellent service for your die casting solutions!

The shipping totally exceeded what I expected, and the packaging was done with great care.

As usual, this company came through for us, delivering not just top-notch die casting solutions but also fantastic service!

After this collaboration, we discovered that the manufacturer has a fantastic service attitude, delivers quickly, and we received everything in no time. Plus, the quality of their die casting solutions is excellent!

Comments are closed.