Custom Injection Molding Services | Fast-Delivery 2024

Best wholesale custom injection molding services from top prototype | low moq & fast delivery discover top prototype! we provide quality custom injection molding services ,& engaged in custom injection molding services market for many yrs.

Discover The Top Prototype Category

Best wholesale custom injection molding services from top prototype | low moq & fast delivery discover top prototype! we provide quality custom injection molding services ,& engaged in custom injection molding services market for many yrs.

Custom Injection Molding Services From Top Prototype: Quality You Can Trust!

Get your hands on TOP Prototype’s High-quality custom injection molding services. When custom injection molding services are essential, turn to TOP Prototype & top custom injection molding services.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

See What People Are Saying About Custom Injection Molding Services: Read Reviews!

Our commitment to quality extends to customers worldwide through our worth buying custom injection molding services.

Interested In What Top Prototype Can Offer With Custom Injection Molding Services? Contact Us Now!

Our not to be missed are renowned for their premium quality, resilience, and ease of upkeep. Delve into our website for comprehensive information.

Faster

When you complete the part design, share it with our company by email and synchronize your requirements.TOP Prototype adopts the most efficient quotation service and focuses on your product requirements.

24/7 Engineering Support

24/7 Engineering Support

TOP Prototype has a team of experienced engineers to provide auxiliary advice for your project, helping you optimize your design, save costs, and achieve better and more consistent quality standards through standardization.

15 +

15 + Years in Business

What are custom injection molding services?

Custom injection molding services are specialized manufacturing processes that create parts by injecting molten material into a mold. These services allow for high precision and the ability to produce complex shapes tailored to specific requirements.

What materials can be used in custom injection molding?

Various materials can be used in custom injection molding, including thermoplastics, thermosetting plastics, and elastomers. Common examples include ABS, polycarbonate, nylon, and polypropylene.

How does the custom injection molding process work?

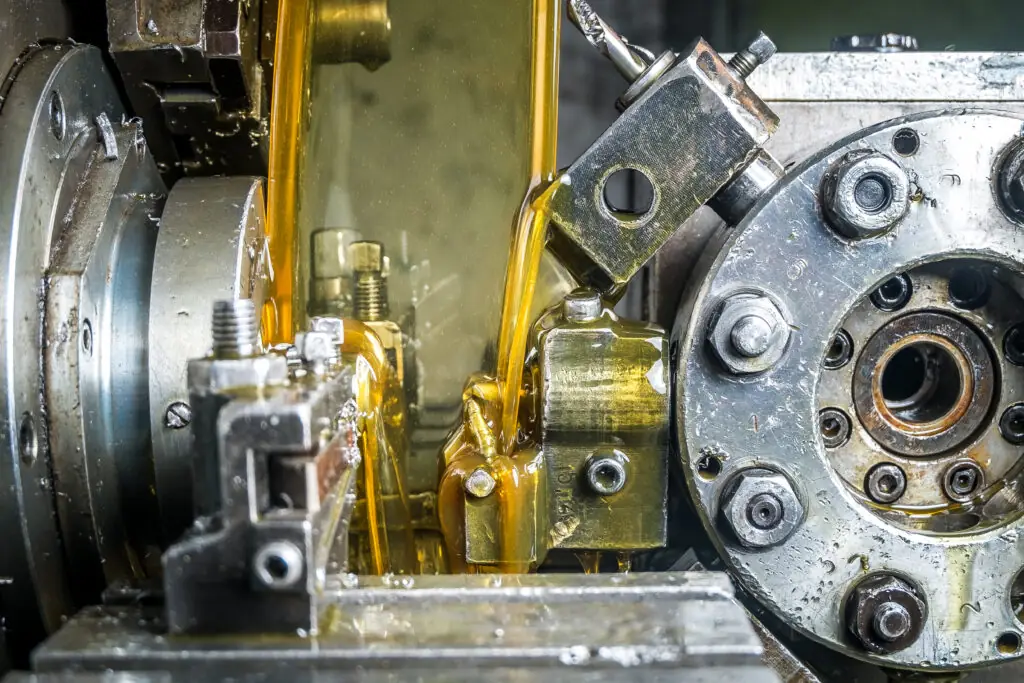

The custom injection molding process involves designing a mold, melting the material, injecting it into the mold under pressure, allowing it to cool and solidify, and then removing the finished part from the mold.

What are the advantages of using custom injection molding services?

The advantages of using custom injection molding services include high production efficiency, consistency in part quality, the ability to create intricate designs, and cost-effectiveness for large production runs.

Top Prototype Offers More Than Custom Injection Molding Services.

TOP Prototype is at the forefront of innovation, providing insights into custom injection molding services to help you stay informed.

Sheet Metal Fabrication Services | Precision & Custom Solutions

Sheet Metal Fabrication Services | Precision & Custom Solutions In the highly competitive automotive industry, sheet metal fabrication plays a pivotal role in shaping the vehicles we drive. It is a complex and precise process that demands the utmost attention to detail and the utilization of advanced technologies. TOP Prototype has emerged as a

Metal Surface Treatment: Processes and Significance

Metal Surface Treatment: Processes and Significance Metal surface treatment is a crucial aspect in the manufacturing and engineering fields. It involves various techniques that modify the surface properties of metals to enhance their performance, durability, and aesthetic appeal. Common Metal Surface Treatment Processes: Anodizing Anodizing is widely used, especially for aluminum. In this process,

Quality Inspection of TOP Prototype Products

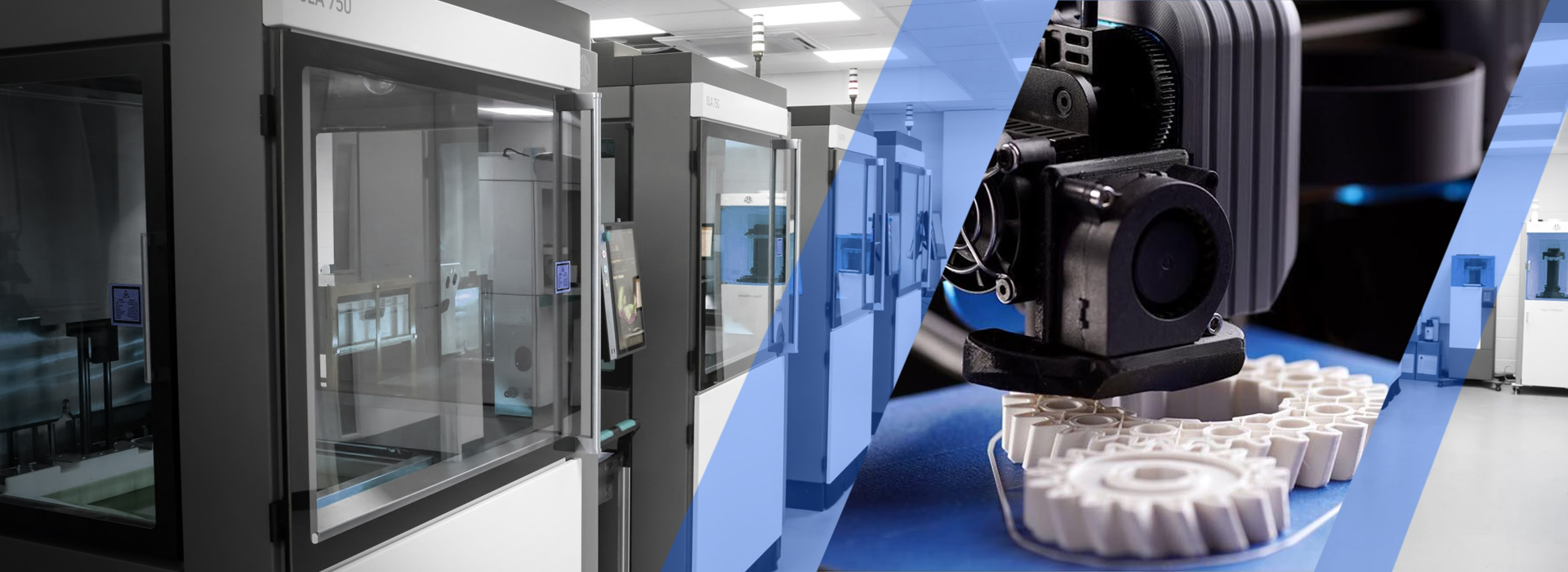

Quality Inspection of TOP Prototype Products In the highly competitive manufacturing industry, ensuring the quality of products is of utmost importance. TOP Prototype, a company specializing in various manufacturing processes such as CNC machining parts, injection molding, sheet metal fabrication, silicone rubber molding, and 3D printing, has established a comprehensive and stringent quality inspection system

Sheet Metal Processing Materials: Characteristics, Applications, and Innovations

Sheet Metal Processing Materials: Characteristics, Applications, and Innovations Sheet metal processing is a vital part of modern manufacturing, and the choice of materials plays a decisive role in the quality and performance of the final products. TOP Prototype, a distinguished company in this domain, has in – depth knowledge and extensive experience in handling

Unraveling the Wonders of TOP Prototype Electroplating: Process, Applications, and Impact

Unraveling the Wonders of TOP Prototype Electroplating: Process, Applications, and Impact What is Electroplating? TOP Prototype is a company that may utilize electroplating in its operations. Electroplating is a process that uses an electric current to deposit a thin layer of metal onto another metal or other conductive surface. In electroplating carried out

Step into the World of TOP Prototype CNC Machined Delights: A Visual Feast

Step into the World of TOP Prototype CNC Machined Delights: A Visual Feast CNC machining has emerged as a revolutionary force, creating a world of precision-engineered wonders that tantalize the eyes and captivate the imagination. TOP Prototype, a renowned name in the industry, has been a key player in this exciting landscape. TOP Prototype’s

More About Custom Injection Molding Services & Top Prototype

We look ahead for your cooperation sincerely. Please contact us. Owning a factory and top-notch technologies, TOP Prototype always offers unmatchable custom injection molding services worldwide. We offer companies product with great price and premium quality, skilled operation is our work, we adhere to honesty and superior faith working attitude. Nowadays with the trend of internationalization, we’ve got decided to reach a broader audience. The custom injection molding services will supply to all over the world, such as West Asia, South Africa, Mexico, Eastern Europe, etc. We are committed to improving production quality and efficiency continually for your satisfaction we also accept Customized Products order, all products have passed professional certification. We are looking forward to cooperating with you and providing our best services for you, as well as our custom injection molding services, Aerospace Manufacturing,SWISS LATHE PROCESSING. With a rich history spanning decades, our factory earned a reputation for advanced technologies, delivering excellence.

Other Categories From Top Prototype

Why Choose Top Prototype Custom Injection Molding Services ?

Custom injection molding services offer a fast and efficient way to produce high-quality plastic parts tailored to specific needs. This manufacturing process involves injecting molten plastic into a precisely designed mold, allowing for intricate designs and consistent production quality. Companies can create a wide range of products, from simple components to complex assemblies, meeting the exact specifications of their projects. With advancements in technology and materials, custom injection molding not only reduces lead times but also enhances durability and functionality, making it an ideal choice for various industries, including automotive, consumer goods, and medical devices.

Innovation Of Custom Injection Molding Services

Custom injection molding services are at the forefront of innovation, providing businesses with the ability to transform ideas into reality with precision and efficiency. By leveraging advanced materials and cutting-edge technology, these services enable rapid prototyping and production of intricate designs, optimizing both functionality and aesthetics. With a focus on technical excellence, custom injection molding ensures high-quality, durable products tailored to meet specific market demands, reducing lead times and fostering an agile development process. Innovating at each stage, from design to execution, these services are essential for companies looking to stay competitive in a fast-paced environment.

Custom Injection Molding Services Cost-Effectiveness

- Cost-Effectiveness: Custom injection molding significantly reduces production costs through efficient material use and minimized waste.

- Scalability: Ideal for both small batch runs and large-scale production, ensuring cost savings at any volume.

- Precision Manufacturing: High accuracy in part dimensions promotes lower tolerance levels and reduces post-production modifications.

- Material Variety: Wide range of thermoplastics and thermosetting materials available to suit specific application needs.

- Rapid Prototyping: Accelerates design iterations and product development cycles, allowing for quick market entry.

- Reduced Labor Costs: Automation in the injection molding process lowers the need for extensive manual labor.

- Consistency and Repeatability: Ensures uniformity in parts across production runs, enhancing product reliability.

Reliability From Top Prototype

- Reliability: Custom injection molding services provide consistent quality and precision, ensuring that each part meets exact specifications.

- Scalability: Easily scalable production from prototypes to large runs without loss of quality or performance.

- Material Versatility: Wide range of materials can be used, including thermoplastics, elastomers, and composites for various applications.

- Cost-Effectiveness: Reduced waste and efficient production processes lead to lower costs over time, especially for high-volume runs.

- Rapid Prototyping: Quick turnaround times for prototypes, allowing for faster testing, iteration, and product development.

- Precision Engineering: High level of detail and accuracy ensures parts fit together flawlessly, reducing assembly and integration issues.

9 thoughts on “Custom Injection Molding Services”

You’ve got top-notch equipment and a bold attitude, even if your prices are higher than others in the industry. But we’re choosing you! Here’s to a partnership that leaves both sides happy with our custom injection molding services.

These awesome custom injection molding services have really lifted my spirits lately, thanks a bunch!

We’re really lucky to have discovered such a fantastic supplier, and we’re thinking about building a long-term partnership with you for our custom injection molding services.

We’re really pleased with this partnership! The turnaround time for the custom injection molding services is super quick, and the packaging is top-notch—everything arrives just right!

Great service goes beyond the surface; it comes from within. The customer support for their custom injection molding services was attentive and thorough in addressing all my questions. I really appreciated how quickly they got back to me!

I’d totally suggest these custom injection molding services to my friends!

We spent quite a while checking out the custom injection molding services from different sellers, and it turned out to be totally worth it. Regardless of their approach or anything else, we had a fantastic experience!

We just got the custom injection molding services, and we’re really happy with them! You’ve been a fantastic supplier, and we look forward to continuing our great work together.

This company in the industry is robust and competitive, keeping up with the times and focusing on sustainability. We’re excited about the chance to collaborate on custom injection molding services!

Comments are closed.