Custom Electronics Prototyping | 7/24 Customer Service

#1 wholesaling custom electronics prototyping from top prototype | free samples top prototype provides innovative custom electronics prototyping ,& owns a long experience, providing top custom electronics prototyping.

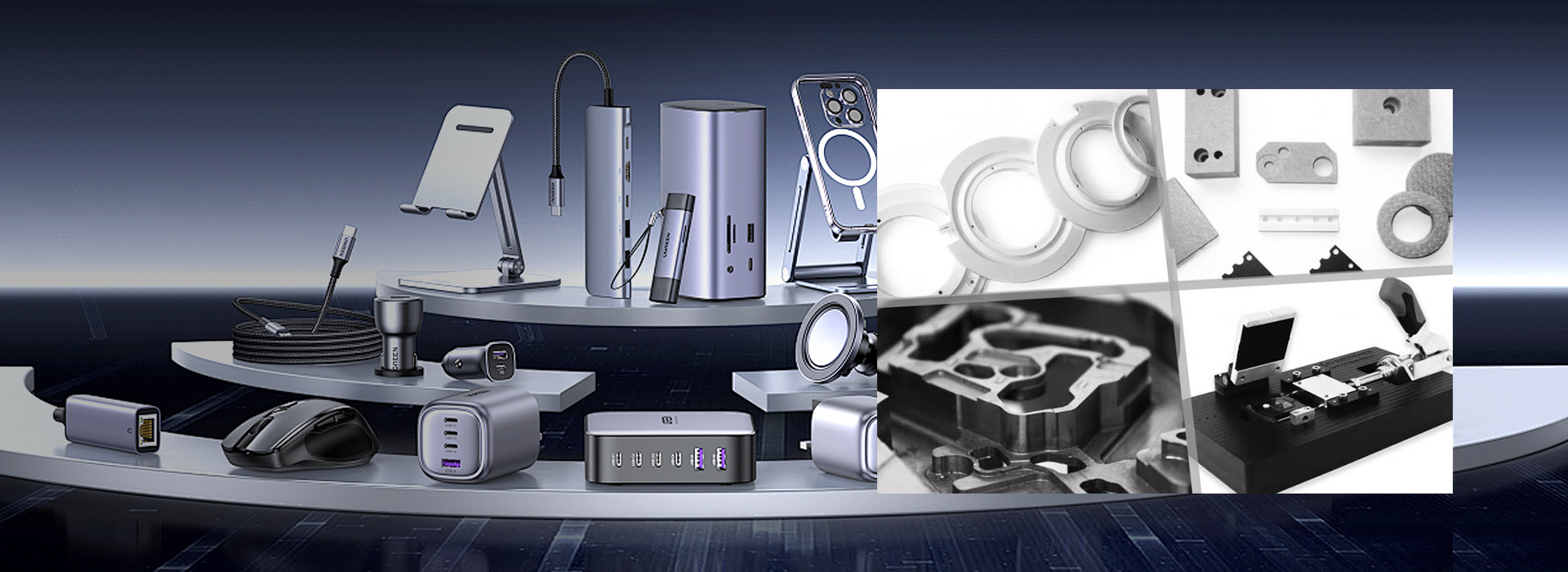

Our Top Prototype Category

#1 wholesaling custom electronics prototyping from top prototype | free samples top prototype provides innovative custom electronics prototyping ,& owns a long experience, providing top custom electronics prototyping.

Custom Electronics Prototyping By Top Prototype: Delivering Excellence!

Get the latest in Innovative custom electronics prototyping at TOP Prototype. If custom electronics prototyping are on your list, it’s worth thinking about TOP Prototype & custom electronics prototyping.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

Customer Insights On Custom Electronics Prototyping: Read Their Reviews Now!

We’re proud to supply carefully curated custom electronics prototyping to a global customer network.

Want To Know How Top Prototype And Custom Electronics Prototyping Work Together? Get In Touch!

Count on our production preferred for their exceptional quality, longevity, and simple maintenance. Visit our website for comprehensive information.

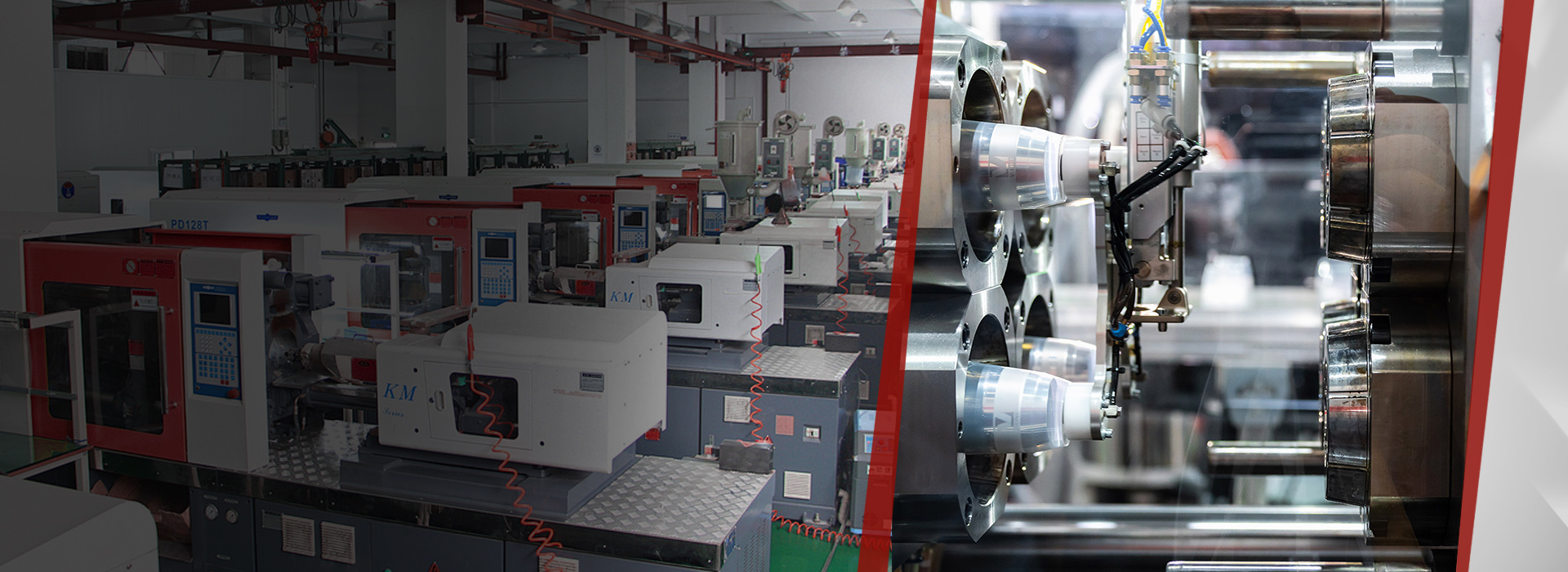

Leading Capabilities

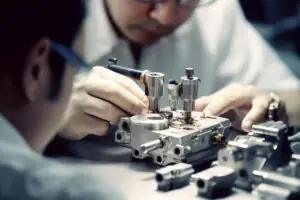

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

Variety

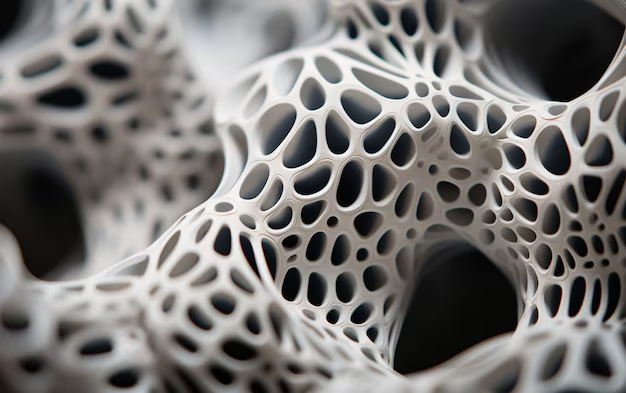

Our services range from prototype design to large-scale production, from CNC lathes to milling centers, injection molding, advanced 3D printing equipment, etc.

15 +

15 + Years in Business

What is custom electronics prototyping?

Custom electronics prototyping is the process of creating a unique electronic device or system tailored to specific requirements, allowing for testing and validation of concepts before full-scale production.

What are the benefits of custom electronics prototyping?

The benefits include the ability to test new ideas, reduce time to market, optimize designs for specific applications, and ultimately create more innovative and effective electronic products.

How long does the custom electronics prototyping process typically take?

The timeline for custom electronics prototyping can vary widely depending on the complexity of the project, but it can range from a few weeks to several months for thorough design, testing, and iteration.

What technologies are commonly used in custom electronics prototyping?

Common technologies include microcontrollers, FPGA (Field-Programmable Gate Arrays), PCB (Printed Circuit Board) design software, and 3D printing for creating physical prototypes of casings and components.

Want To Know More About Custom Electronics Prototyping?

Discover how TOP Prototype’s commitment to excellence enriches the landscape of custom electronics prototyping for all enthusiasts.

Case study :TOP Prototype and Tesla’s extraordinary wheel kit

Case study :TOP Prototype and Tesla’s extraordinary wheel kit Wondering about CNC machining and why it’s so important in manufacturing? You’re not alone. Computer numerical control (CNC) machining is a key role in modern manufacturing, utilizing advanced technology to cut, shape and manufacture precision parts. This article details the working principle of CNC machine tools

TOP Pototype collaborates with Extremis: Outdoor Equipment Innovation

TOP Pototype collaborates with Extremis: Outdoor Equipment Innovation Wondering about CNC machining and why it’s so important in manufacturing? You’re not alone. Computer numerical control (CNC) machining is a key role in modern manufacturing, utilizing advanced technology to cut, shape and manufacture precision parts. This article details the working principle of CNC machine tools and

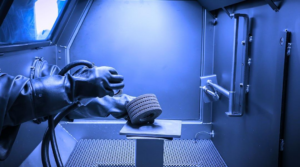

Black Oxide: A Versatile Surface Treatment

Black Oxide: A Versatile Surface Treatment Introduction Surface treatment plays a crucial role in enhancing the properties and appearance of various materials. One such method is black oxide, which has gained popularity in numerous industries. This article will explore the definition, working principle, technical knowledge, advantages, and industry applications of black oxide, with references to

All You Need to Know about SLA Manufacturing in the Medical Industry

In the world of 3D printing, SLA manufacturing holds a special place, especially in industries where extreme precision and fine detail are critical. One specific field is the medical industry, where precise, tailored, and biocompatible components may have a life-changing impact. Among the numerous additive manufacturing methods, SLA manufacturing has become a preferred method for

Sandblasting: An In-Depth Exploration

Sandblasting: An In-Depth Exploration Introduction Sandblasting is a versatile and widely used process that has found applications in numerous industries. It involves the use of high-velocity streams of abrasive materials to clean, smooth, or shape a variety of surfaces. This technique has proven to be invaluable in areas such as manufacturing, construction,

Sheet Metal Processing Materials: Characteristics, Applications, and Innovations

Sheet Metal Processing Materials: Characteristics, Applications, and Innovations Sheet metal processing is a vital part of modern manufacturing, and the choice of materials plays a decisive role in the quality and performance of the final products. TOP Prototype, a distinguished company in this domain, has in – depth knowledge and extensive experience in handling

More About Custom Electronics Prototyping & Top Prototype

TOP Prototype is dedicated into the market to providing premium custom electronics prototyping and service worldwide. We will continually strive to improve our service, we stick to the operating principle of credit first, trust builds our path to success. We are looking forward to cooperating with you and providing our best services for you, as well as our custom electronics prototyping, Aerospace Manufacturing,SWISS LATHE PROCESSING. Maybe you are looking for good quality at an affordable price and timely delivery. For further information, please don’t hesitate to contact with us. Our R&D team has extensive experience to provide you expert support, tailoring production according to your needs is fine, we ensure that every product meets the criteria for professional certification. We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. The world is our market – this custom electronics prototyping will be supplied globally to West Asia, South Africa, Canada, Eastern Europe, etc. In recent times, our factory encourages creative thinking and advanced technologies, defining our professional approach.

Other Categories From Top Prototype

Why Choose Top Prototype Custom Electronics Prototyping ?

Custom electronics prototyping has become an essential part of the innovation landscape, enabling creators and businesses to bring their ideas to fruition quickly and efficiently. This process allows designers to test concepts, refine functionalities, and validate designs before full-scale production. As the demand for unique, tailored solutions grows, rapid prototyping emerges as a vital tool, facilitating iteration and adaptation in response to user feedback and technological advancements. Whether it’s developing smart devices, IoT applications, or wearable technology, the ability to prototype custom electronics swiftly can significantly enhance the overall development cycle, reducing time to market while ensuring high-quality outcomes that meet specific user needs. In this dynamic environment, tools and methods are continually evolving, making it easier than ever to turn visionary ideas into tangible products.

Environmental Impact Of Custom Electronics Prototyping

Custom electronics prototyping presents a unique intersection of innovation and environmental stewardship. As we endeavor to create tailored devices, the imperative to minimize ecological footprints becomes paramount. Employing sustainable materials and energy-efficient designs not only mitigates waste but also enhances the lifecycle of electronic products. By adopting environmentally conscious practices, such as reducing hazardous substances and prioritizing recyclability, we can foster an ecosystem that champions both technological advancement and ecological integrity. In this dynamic landscape, the principles of rapid prototyping can be harnessed to swiftly iterate designs that are not only functional but also harmoniously aligned with the planet’s wellbeing.

Custom Electronics Prototyping Innovation

- Innovation Catalyst: Custom electronics prototyping serves as a crucible for groundbreaking ideas, transforming nascent concepts into tangible products through iterative design.

- Rapid Iteration: With agile methodologies, prototypes can be swiftly modified, enabling designers to refine functionality and aesthetics in real-time.

- Market Adaptability: Prototyping allows for quick responsiveness to market trends and consumer needs, ensuring products remain relevant and competitive.

- Cost Efficiency: Early-stage prototyping mitigates financial risks by validating assumptions before large-scale production, optimizing resource allocation.

- Collaborative Synergy: Engaging multidisciplinary teams fosters diverse perspectives, enhancing creativity and leading to multifaceted solutions.

- Technological Integration: Rapid prototyping leverages advanced tools and materials, facilitating the seamless incorporation of cutting-edge technologies.

- User-Centric Design: Prototypes provide valuable insights through user testing, aligning product development with end-user experiences and preferences.

Safety From Top Prototype

- Safety First: Prioritize user and equipment safety through meticulous design.

- Robust Testing: Implement rigorous validation protocols to mitigate risks.

- Material Selection: Choose components that adhere to safety standards and environmental regulations.

- Thermal Management: Designing for optimal heat dissipation to prevent overheating.

- Failure Analysis: Employ predictive maintenance techniques to foresee potential failures.

- Documentation: Maintain comprehensive records for traceability and compliance.

- User-Centric Design: Engage end-users to ensure intuitive operation and safety features.

8 thoughts on “Custom Electronics Prototyping”

The custom electronics prototyping works like a charm and is really awesome overall!

I just got my custom electronics prototyping, and I’m really impressed with how quickly it arrived—right the next morning! I’m loving it; it’s fantastic!

The customer service and sales team are fantastic! They helped me with all my questions and concerns. How could I not feel at ease when purchasing custom electronics prototyping like this?

The quality of the custom electronics prototyping is excellent, just like the seller said, and it really blew me away!

I’ve been using it for a bit now, and it still looks brand new with no problems at all. It fits just right!

We’ve been partnering with this manufacturer for a while now, and they have an awesome team that’s always ready to tackle any issues you might have and cater to your custom electronics prototyping needs!

After working together, I’ve found that this company’s custom electronics prototyping and delivery service are top-notch. I definitely suggest giving them a shot!

I can’t praise this collaboration enough! We were really happy with the fair pricing, the friendly approach to any issues, and the top-notch quality of the custom electronics prototyping. Looking forward to more projects together!

Comments are closed.