Custom Die Casting Solution | Industry Leaders

Custom die casting solution from the best manufacturer & wholesaler top prototype. search top prototype, who provides innovative custom die casting solution. we devote to custom die casting solution market for several yrs.

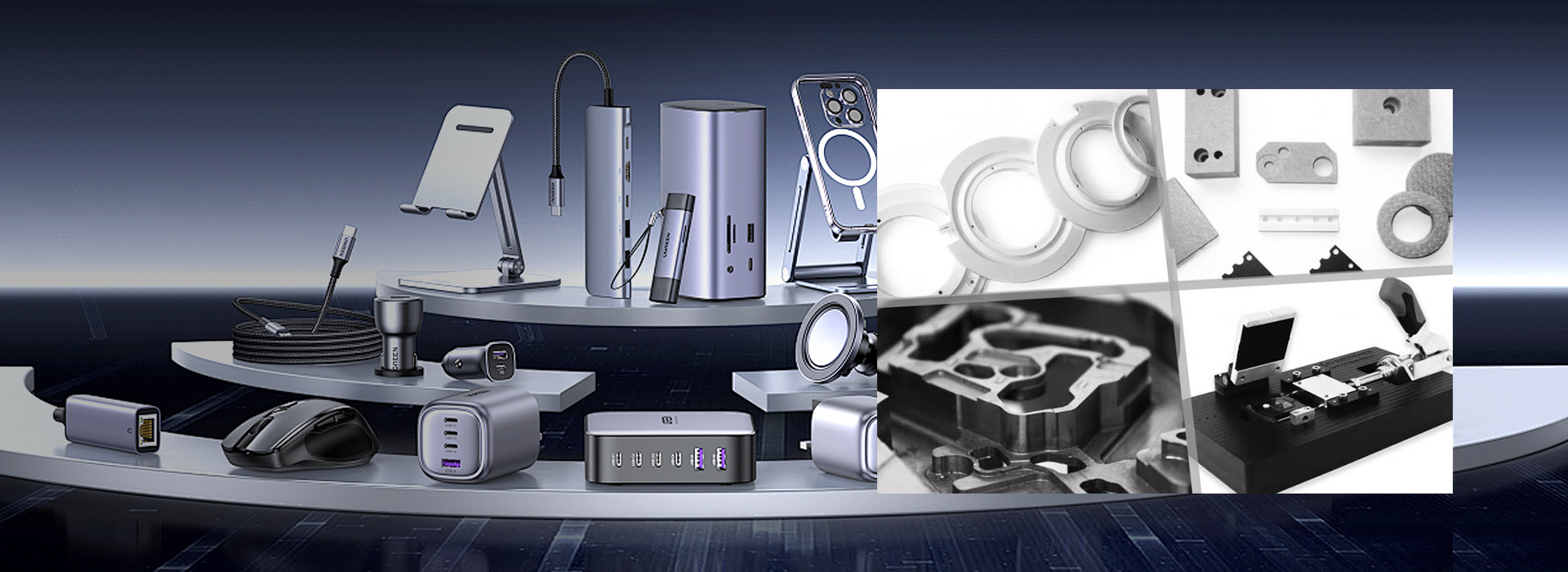

Check Out Our Top Prototype Category

Custom die casting solution from the best manufacturer & wholesaler top prototype. search top prototype, who provides innovative custom die casting solution. we devote to custom die casting solution market for several yrs.

Custom Die Casting Solution – Enhance Your Profit Margins With Top Prototype!

Uncover Innovative custom die casting solution in the selection from TOP Prototype. If custom die casting solution are on your list, it’s worth thinking about TOP Prototype & custom die casting solution.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

See What People Are Saying About Custom Die Casting Solution: Read Reviews!

Our clientele spans the globe as we provide unique custom die casting solution to customers worldwide.

Interested In Custom Die Casting Solution? Contact Us Now!

You can expect our the best to be top-quality, long-lasting, and straightforward to maintain. Learn more by visiting our website.

Faster

When you complete the part design, share it with our company by email and synchronize your requirements.TOP Prototype adopts the most efficient quotation service and focuses on your product requirements.

Variety

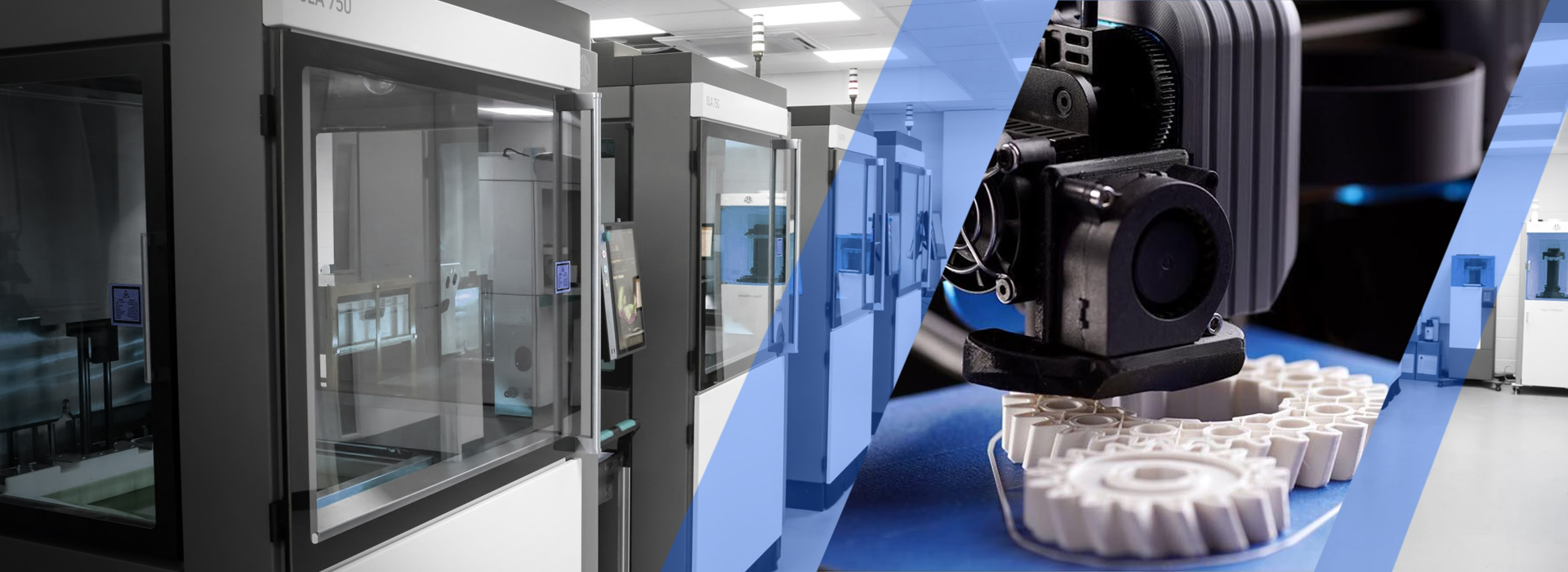

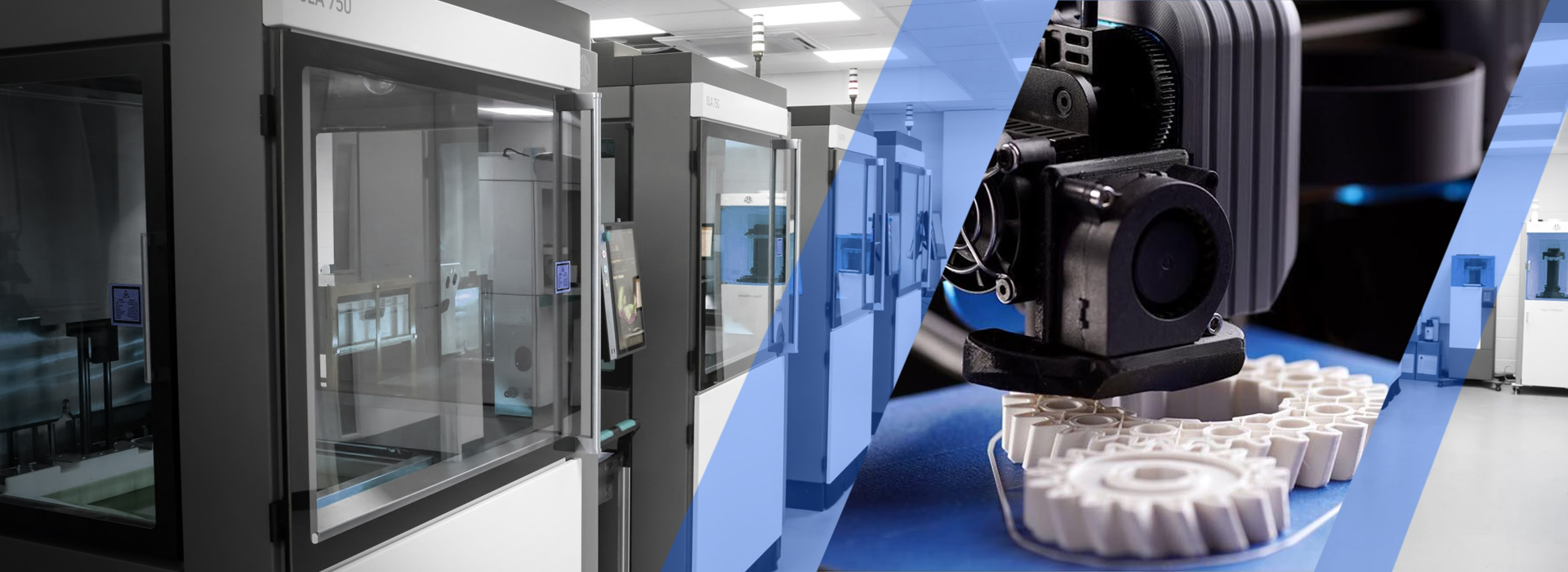

Our services range from prototype design to large-scale production, from CNC lathes to milling centers, injection molding, advanced 3D printing equipment, etc.

60 +

60 + Countries Countries shipped

What is a custom die casting solution?

A custom die casting solution is a manufacturing process that involves creating metal parts by pouring molten metal into a mold designed specifically for a unique application or product requirements. This process allows for high precision and complex shapes.

What materials are commonly used in custom die casting?

Common materials for custom die casting include aluminum, zinc, magnesium, and copper alloys. Each material has its own properties that can be selected based on the intended use of the final product.

What industries benefit from custom die casting solutions?

Industries such as automotive, aerospace, electronics, and consumer goods benefit significantly from custom die casting solutions due to the need for lightweight, durable, and complex parts.

How does the custom die casting process affect production costs?

The custom die casting process can lower production costs for large volumes due to its efficiency and speed, although initial costs for mold design and creation can be high. However, these costs are often offset by the reduction in labor and material waste during mass production.

Want To Know More About Custom Die Casting Solution?

With a focus on custom die casting solution, TOP Prototype offers comprehensive resources to deepen your understanding and application.

Step into the World of TOP Prototype CNC Machined Delights: A Visual Feast

Step into the World of TOP Prototype CNC Machined Delights: A Visual Feast CNC machining has emerged as a revolutionary force, creating a world of precision-engineered wonders that tantalize the eyes and captivate the imagination. TOP Prototype, a renowned name in the industry, has been a key player in this exciting landscape. TOP Prototype’s

Quality Inspection of TOP Prototype Products

Quality Inspection of TOP Prototype Products In the highly competitive manufacturing industry, ensuring the quality of products is of utmost importance. TOP Prototype, a company specializing in various manufacturing processes such as CNC machining parts, injection molding, sheet metal fabrication, silicone rubber molding, and 3D printing, has established a comprehensive and stringent quality inspection system

Sheet Metal Cutting Processes: An In – depth Analysis

Sheet Metal Cutting Processes: An In – depth Analysis

3 Key Benefits of Sheet Metal Fabrication

3 Key Benefits of Sheet Metal Fabrication Sheet metal fabrication offers three significant benefits: cost-effectiveness, durability, and versatility. These advantages make it an ideal choice for a wide range of projects. The process becomes more cost-effective as production volume increases, reducing per-unit costs. This affordability, combined with the material’s inherent strength and resistance to environmental

Definition and Significance of TOP Prototype Sheet Metal

Definition and Significance of TOP Prototype Sheet Metal Sheet metal is an essential component in the manufacturing and engineering industries. TOP Prototype, a renowned company in this field, has extensive experience in handling sheet metal. It plays a crucial role in the production of a wide variety of products, ranging from automobiles and aircraft

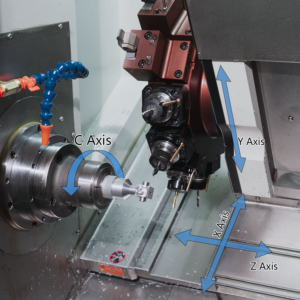

CNC Programming: Concepts and Commonly Used Languages

CNC Programming: Concepts and Commonly Used Languages Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry, enabling the production of highly precise and complex parts with ease. At the heart of CNC machining lies programming, which dictates the movements and operations of the machine tools. In this article, we will explore the basic concepts

More About Custom Die Casting Solution & Top Prototype

We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. The world is our market – this custom die casting solution will be supplied globally to West Asia, South Africa, Canada, Eastern Europe, etc. TOP Prototype collaborates with many factories and qualitified team to provide expert and affordable custom die casting solution to global customers. We are looking forward to cooperating with you and providing our best services for you, as well as our custom die casting solution, Aerospace Manufacturing,SWISS LATHE PROCESSING. Through recent years, our company leads the industry for innovative technologies, exceeding the industry standard. Our excellent management, strong technical capability and strict quality control system, help to provide our clients with reliable quality, tailoring production according to your needs is fine, each product has been professionally certified to meet industry standards. With us, your safety is guaranteed. We warmly welcome you to contact us and please feel free to speak out your needs We will continue to carry forward the spirit of high quality, efficiency, innovation, integrity, innovation and integrity guide our path, trust builds our path to success.

Other Categories From Top Prototype

Why Choose Top Prototype Custom Die Casting Solution ?

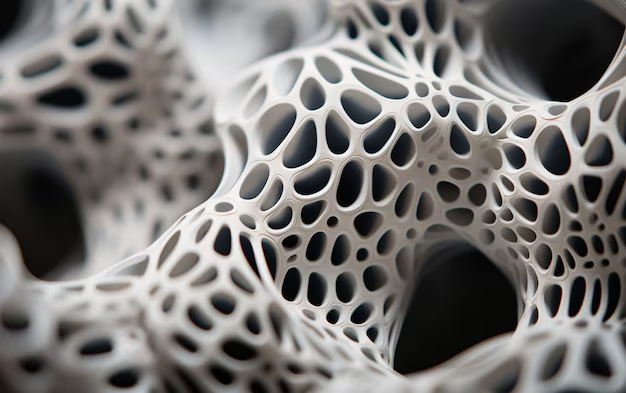

In the realm of manufacturing, custom die casting solutions offer unparalleled efficiency and precision, particularly when utilizing an indirect tempering process. This innovative technique enhances the durability and integrity of metal components by allowing controlled cooling and reheating cycles. As a result, manufacturers can produce intricate parts with exceptional surface finishes and tight tolerances, making it ideal for industries ranging from automotive to aerospace. With the ability to create complex geometries and reduce production times, custom die casting stands at the forefront of modern engineering, providing tailored solutions that meet the unique demands of each project while ensuring high-quality outcomes.

Innovation Of Custom Die Casting Solution

In the fast-evolving landscape of manufacturing, custom die casting solutions stand at the forefront of innovation. These solutions enable the rapid transformation of design concepts into high-quality, precision-engineered components. By leveraging advanced materials and cutting-edge technologies, custom die casting offers unparalleled flexibility and efficiency, catering to the unique needs of various industries. Emphasizing both speed and accuracy, this approach streamlines production timelines while maintaining the highest standards of excellence, making it an indispensable asset for businesses seeking to enhance their competitive edge.

Custom Die Casting Solution Environmental Impact

- Eco-Friendly Materials: Utilize recyclable metals, such as aluminum and zinc, which reduce waste and promote sustainability.

- Energy Efficiency: Advanced die casting technologies minimize energy consumption during production, lowering carbon footprints.

- Waste Reduction: Precision in manufacturing leads to less scrap material, optimizing resource use and minimizing landfill impact.

- Long-Lasting Products: Durable die cast components contribute to longevity and reduced frequency of replacement, further conserving resources.

- Controlled Emissions: Implementing modern techniques to lower emissions during casting processes aligns with environmental regulations and standards.

- Lifecycle Analysis: Regular assessments to improve processes and materials, ensuring ongoing commitment to sustainability.

Aesthetics From Top Prototype

- Aesthetics: Custom die casting solutions offer unparalleled design flexibility, allowing intricate shapes, textures, and finishes that enhance product appeal.

- Material Versatility: A variety of metals—such as aluminum, zinc, and magnesium—can be used, each providing distinct aesthetic properties and functionalities.

- Surface Finishing: Options for anodizing, powder coating, and polishing enable a wide range of aesthetic outcomes, catering to diverse customer preferences.

- Precision Engineering: High dimensional accuracy ensures that design intentions are faithfully realized, resulting in visually appealing and functional products.

- Rapid Prototyping: Speed up the development process by creating prototypes that help visualize aesthetics before full-scale production.

- Cost Efficiency: Optimizing designs early in the prototyping phase can significantly reduce costs, making custom aesthetics accessible for various budgets.

7 thoughts on “Custom Die Casting Solution”

We really love how your custom die casting solutions are designed in such an innovative way, staying current and showcasing your unique perspective in the details.

The custom die casting solution is fantastic, and the seller really knows their stuff. They take payment upfront before starting the design, which shows they’re a trustworthy and reliable businessperson!

This custom die casting solution is fantastic, and the price is just right!

Initially, we had some concerns about the quality of the custom die casting solution, but once it arrived, we were pleasantly surprised. The delivery was quick, and the product felt really sturdy. It looks like it’s going to hold up for a long time!

You can’t really complain about the quality of their custom die casting solutions. The craftsmanship and materials are top-notch, the installation team is friendly and attentive, and they take great care during the setup process. Plus, the seller’s service is excellent!

These custom die casting solutions are fantastic, and I’m really enjoying them!

I really love your custom die casting solutions! They’ve been fantastic for me, and I’ve kept them in great shape over the past few months. They’re definitely my favorite products!

Comments are closed.