Ceramic Rapid Prototyping | Fast-Delivery 2024

#1 ceramic rapid prototyping from top prototype | china manufacturer | fast delivery. discover top prototype! we provide trustworthy ceramic rapid prototyping ,& engaged in ceramic rapid prototyping market for many yrs.

Explore Our Top Prototype Offerings

#1 ceramic rapid prototyping from top prototype | china manufacturer | fast delivery. discover top prototype! we provide trustworthy ceramic rapid prototyping ,& engaged in ceramic rapid prototyping market for many yrs.

Ceramic Rapid Prototyping Boost Your Profit!

Choose from a wide range of Innovative ceramic rapid prototyping at TOP Prototype. TOP Prototype offers ceramic rapid prototyping that should be on your radar for ceramic rapid prototyping.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

Ceramic Rapid Prototyping: Discover Customer Reviews And Feedback!

Our clientele spans the globe as we provide high-quality ceramic rapid prototyping to customers worldwide.

Curious About Ceramic Rapid Prototyping? Don’T Hesitate To Reach Out!

Our jigh-performance are well-regarded for their excellence, longevity, and minimal maintenance needs. Explore our website for in-depth information.

Faster

When you complete the part design, share it with our company by email and synchronize your requirements.TOP Prototype adopts the most efficient quotation service and focuses on your product requirements.

More Responsive Quotes

We will give you feedback within 1 hour to ensure that you receive professional processing suggestions, lower processing costs and a faster delivery time.

60 +

60 + Countries Countries shipped

What is ceramic rapid prototyping?

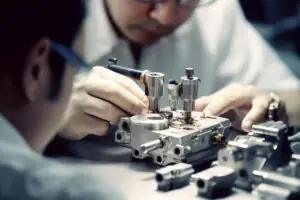

Ceramic rapid prototyping is a manufacturing process that allows for the quick and efficient creation of ceramic parts and components using additive manufacturing techniques, such as 3D printing, to produce complex shapes and designs not easily achievable with traditional methods.

How does ceramic rapid prototyping differ from traditional ceramic manufacturing?

Unlike traditional ceramic manufacturing, which often involves time-consuming processes like molding and firing, ceramic rapid prototyping allows for faster iterations and the ability to produce customized designs directly from digital models, reducing lead times and material waste.

What are the advantages of using ceramic rapid prototyping in industry?

The advantages of ceramic rapid prototyping include reduced production times, the ability to create complex geometries, lower material waste, and the potential for customization, making it ideal for applications in fields such as aerospace, medical, and electronics.

What materials can be used in ceramic rapid prototyping?

Various ceramic materials can be used in ceramic rapid prototyping, including alumina, zirconia, and silicon carbide, which can be processed in different ways depending on the desired properties and applications of the final product.

Learn More About Ceramic Rapid Prototyping With Top Prototype!

TOP Prototype is at the forefront of innovation, providing insights into ceramic rapid prototyping to help you stay informed.

Bearing type: Characteristics and applications

Bearing type: Characteristics and applications If we break down rotating mechanical devices, systems or mechanisms, the different movements of their components are essential to their function. For example, blades rotate around the hub of a wind turbine to generate electricity. Do you know which devices or components control and indicate the desired movement within a

3 Key Benefits of Sheet Metal Fabrication

3 Key Benefits of Sheet Metal Fabrication Sheet metal fabrication offers three significant benefits: cost-effectiveness, durability, and versatility. These advantages make it an ideal choice for a wide range of projects. The process becomes more cost-effective as production volume increases, reducing per-unit costs. This affordability, combined with the material’s inherent strength and resistance to environmental

The Power of TOP Prototype Powder Coating

The Power of TOP Prototype Powder Coating Powder coating by TOP Prototype is a revolutionary finishing process that has gained significant popularity in various industries due to its numerous advantages and unique characteristics. In this article, we will explore the concept, working principle, history, and advantages of powder coating offered by TOP Prototype. I. Concept

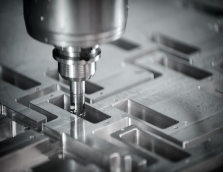

CNC Machining Tolerance: Significance & Standard & Dependence

CNC prototype machining is all about precision. It produces parts with relative quality and relative dimensional accuracy. Relative to the process, one of the more integral components of it is CNC machining tolerances. It is the acceptable measurement of deviation in the dimension of a part. These tolerances indicate how exact a part is within

Sheet Metal Fabrication Services | Precision & Custom Solutions

Sheet Metal Fabrication Services | Precision & Custom Solutions In the highly competitive automotive industry, sheet metal fabrication plays a pivotal role in shaping the vehicles we drive. It is a complex and precise process that demands the utmost attention to detail and the utilization of advanced technologies. TOP Prototype has emerged as a

More About Ceramic Rapid Prototyping & Top Prototype

We are looking forward to cooperating with you and providing our best services for you, as well as our ceramic rapid prototyping, Aerospace Manufacturing,SWISS LATHE PROCESSING. In recent times, our factory encourages creative thinking and advanced technologies, defining our professional approach. We welcome you to establish business relation with us. We welcome customers all over the world to contact us or visit our company. We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, commercial esteem. Our ceramic rapid prototyping will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc. Our purpose is to fulfill our clients’ need, skilled performance is our work, trust paves our way to success. Our advanced production facilities ensure high-qualiy products, we accept and consider all orders with unique specifications, we ensure that every product meets the criteria for professional certification. TOP Prototype is dedicated into the market to providing premium ceramic rapid prototyping and service worldwide.

Other Categories From Top Prototype

Why Choose Top Prototype Ceramic Rapid Prototyping ?

Have you ever thought about how cool it would be to create ceramic objects in a flash? Welcome to the world of ceramic rapid prototyping! This innovative approach lets designers and artists bring their ideas to life with incredible speed and precision. Using advanced technologies like 3D printing, you can whip up everything from intricate vases to unique dinnerware without the usual hassles of traditional ceramics. The process not only saves time but also opens the door to unlimited creativity, making it super easy to experiment with different shapes and sizes. Plus, you get to enjoy the beautiful, earthy feel of ceramics without the long wait. So, if you’re ready to dive into a world where your imagination can run wild, ceramic rapid prototyping is the way to go!

Durability Of Ceramic Rapid Prototyping

Ceramic rapid prototyping has emerged as a pivotal technique in modern manufacturing, facilitating the rapid development and production of complex ceramic components. This process leverages advanced technologies, such as 3D printing and additive manufacturing, to create intricate designs with high precision. One of the most significant advantages of ceramic materials is their exceptional durability; they exhibit remarkable resistance to wear, heat, and corrosion. These properties make them highly suitable for applications in aerospace, biomedical, and industrial sectors. Moreover, the ability to prototype ceramics rapidly allows for iterative design improvements, enabling researchers and engineers to explore innovative solutions while significantly reducing time-to-market. In summary, ceramic rapid prototyping combines efficiency with the inherent strengths of ceramic materials, driving advancements across various fields of engineering and technology.

Ceramic Rapid Prototyping Safety

- Definition: Ceramic rapid prototyping involves the use of advanced techniques to quickly create ceramic components from digital designs.

- Safety Considerations:

- Potential hazards include exposure to dust and particles during the machining and finishing processes.

- Proper ventilation and personal protective equipment (PPE) are critical to ensure worker safety.

- Handling of high-temperature materials requires precautions to prevent burns and injuries.

- Academic Relevance:

- Research on ceramic materials enhances understanding of their properties and applications in various fields.

- Innovations in rapid prototyping contribute to advancements in manufacturing and material science.

- Collaborative projects across disciplines drive new insights into the efficiencies of production methods.

Energy Efficiency From Top Prototype

- Definition: Ceramic rapid prototyping refers to the expedited creation of ceramic components using advanced manufacturing techniques.

- Energy Efficiency: Utilizes less energy compared to traditional ceramic manufacturing methods by optimizing processes.

- Material Waste Reduction: Minimizes waste through precise material usage and additive manufacturing, leading to lower energy expenditure in production.

- Process Innovation: Incorporates techniques like 3D printing that require lower temperatures, reducing overall energy consumption during fabrication.

- Lifecycle Considerations: Promotes sustainability by enabling the design of lighter and more efficient components, ultimately lowering energy demands in their operational phases.

- Research Impact: Ongoing studies focus on enhancing energy efficiency metrics, contributing to a more sustainable ceramics industry.

6 thoughts on “Ceramic Rapid Prototyping”

We’ve always had a great appreciation for the company and are thrilled to collaborate with them. They offer such considerate service to all their customers, and the quality of their ceramic rapid prototyping has consistently been top-notch!

This ceramic rapid prototyping tool is definitely one of my top picks from all the stuff I got while moving!

Quick delivery! I’ll swing by again when I get the chance!

From our long-term collaboration, it’s clear that the company is committed to a responsible service approach and works hard to create top-notch ceramic rapid prototyping products, which has earned our trust.

This company is great at meeting our needs for ceramic rapid prototyping in terms of quantity and delivery time, so we always go with them whenever we need to make a purchase.

This manufacturer not only honored our preferences and needs but also offered us plenty of great suggestions. In the end, we successfully wrapped up our procurement tasks for ceramic rapid prototyping!

Comments are closed.