Carbon Rapid Prototyping | 45% Cost Cut

High-quality wholesale carbon rapid prototyping from top prototype | factory direct sales discover top prototype! we provide reliable carbon rapid prototyping ,& engaged in carbon rapid prototyping market for many yrs.

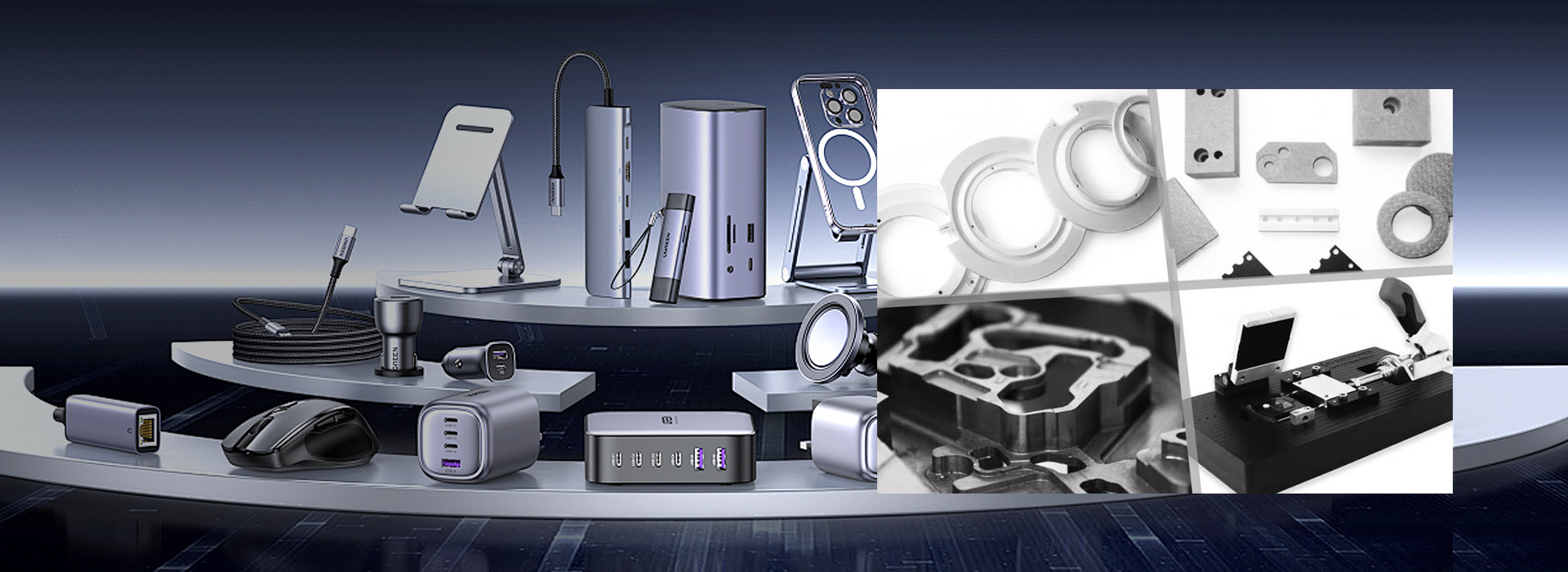

Browse Our Top Prototype Category

High-quality wholesale carbon rapid prototyping from top prototype | factory direct sales discover top prototype! we provide reliable carbon rapid prototyping ,& engaged in carbon rapid prototyping market for many yrs.

Carbon Rapid Prototyping By Top Prototype: Delivering Excellence!

Find exceptional Innovative carbon rapid prototyping options at TOP Prototype. When in search of carbon rapid prototyping, TOP Prototype is trustworthy to consider and provides good carbon rapid prototyping.

PE(polyethylene)

Excellent strength-to-weight ratio, impact resistance and weather resistance.

Carbon Rapid Prototyping: Discover Customer Reviews And Feedback!

We have a strong international presence, delivering top-quality carbon rapid prototyping to customers globally.

Want To Know More About Carbon Rapid Prototyping And How It Can Benefit You?

Our high-quality are well-regarded for their excellence, longevity, and minimal maintenance needs. Explore our website for in-depth information.

Variety

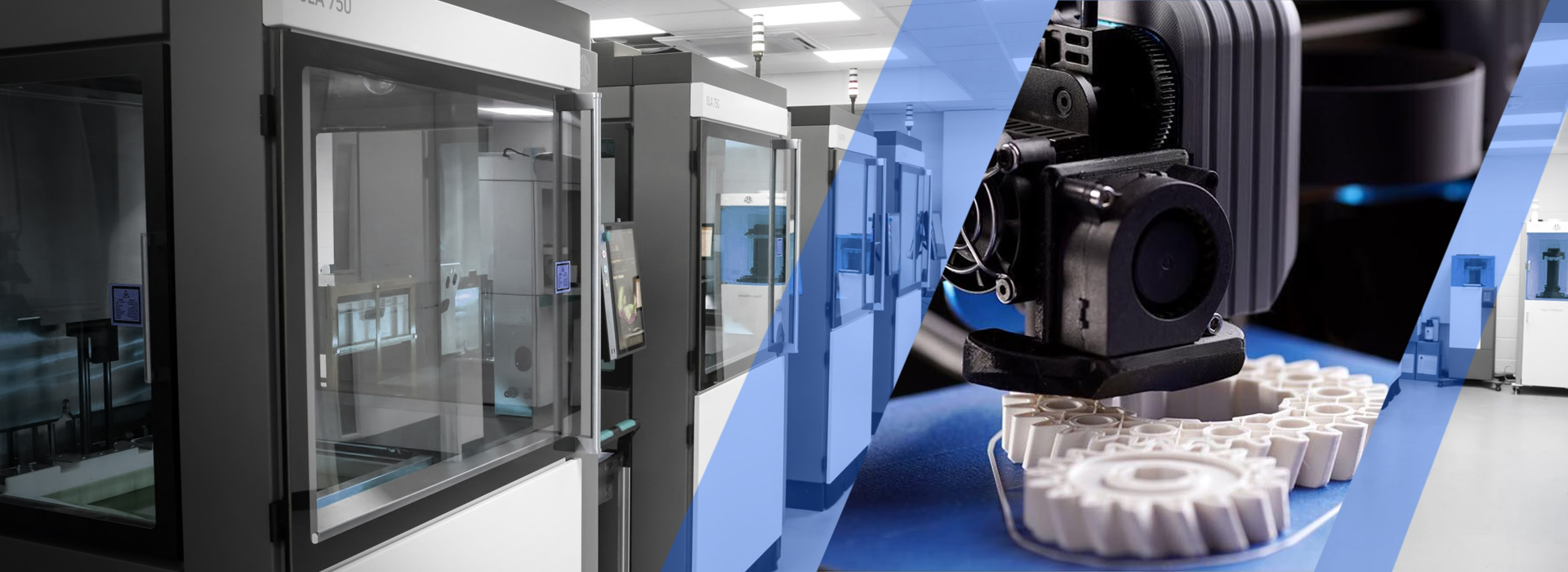

Our services range from prototype design to large-scale production, from CNC lathes to milling centers, injection molding, advanced 3D printing equipment, etc.

400,000 +

Uniquely designed parts produced 400,000 +

15 +

15 + Years in Business

What is carbon rapid prototyping?

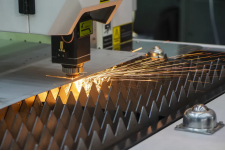

Carbon rapid prototyping refers to a manufacturing process that utilizes Carbon’s Digital Light Synthesis technology to create prototypes quickly and efficiently using liquid resin. This process allows for the production of high-quality, durable parts in a fraction of the time compared to traditional methods.

How does Carbon rapid prototyping differ from traditional 3D printing?

Unlike traditional 3D printing, which typically builds objects layer by layer, Carbon rapid prototyping uses a continuous process that results in smoother surfaces and better mechanical properties. This method allows for faster production and more complex geometries.

What industries can benefit from carbon rapid prototyping?

Carbon rapid prototyping can benefit various industries, including automotive, aerospace, healthcare, and consumer goods, by providing rapid design iteration and faster time-to-market for new products.

What materials are used in carbon rapid prototyping?

Carbon rapid prototyping primarily uses a range of photopolymer resins that can be engineered for specific properties, such as flexibility, strength, or heat resistance, allowing for tailored solutions for different applications.

Curious About Carbon Rapid Prototyping? Check What Top Prototype Has To Offer!

With a focus on carbon rapid prototyping, TOP Prototype offers comprehensive resources to deepen your understanding and application.

TOP Prototype 2023 Chinese New Year holiday Notice

Notice on the 2024 Spring Festival holiday Greetings, As December approaches, Christmas cheer is in the air! Greetings, As December approaches, Christmas cheer is in the air! All of us at TOP Prototype are excited to send you our warmest holiday wishes. Looking ahead, the New Year and Chinese New Year are just around the

CNC Programming: Concepts and Commonly Used Languages

CNC Programming: Concepts and Commonly Used Languages Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry, enabling the production of highly precise and complex parts with ease. At the heart of CNC machining lies programming, which dictates the movements and operations of the machine tools. In this article, we will explore the basic concepts

Mastering CNC Milling: TOP Prototype’s Expertise in

Mastering CNC Milling: TOP Prototype’s Expertise in The Significance of CNC Milling in Modern Industry CNC milling stands as a cornerstone in the manufacturing landscape. It has revolutionized the way complex parts are fabricated. In this era of advanced technology, TOP Prototype has emerged as a key player in harnessing the full potential of CNC

Key Advantages Propelling the Popularity of Injection Molding

Key Advantages Propelling the Popularity of Injection Molding Exceptional Precision and Dimensional Accuracy Injection molding, as practiced by TOP Prototype, offers an outstanding level of precision that is crucial in many industries. The molds used in the process are fabricated with utmost care and accuracy, often with tolerances in the micrometer range. This

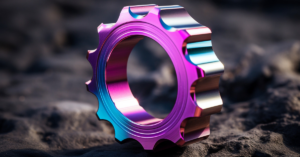

Understanding Anodizing with TOP Prototype: Process, Applications and Challenges

Understanding Anodizing with TOP Prototype: Process, Applications and Challenges I. Introduction What Is Anodizing? Anodizing represents an electrochemical process that transforms the metal surface into a decorative, durable, and corrosion – resistant anodic oxide finish. Among nonferrous metals, while magnesium and titanium can also undergo anodizing, aluminum is the most suitable for this

More About Carbon Rapid Prototyping & Top Prototype

We are committed to improving production quality and efficiency continually for your satisfaction we also accept Customized Products order, all products have passed professional certification. Let us cooperate hand in hand to make a good future. Don’t hesitate to contact for a free quote and further information! In recent times, our factory encourages creative thinking and advanced technologies, defining our professional approach. As a reliable and professional company, TOP Prototype partners with skilled tech teams and offers the best solutions as well as carbon rapid prototyping to global customers. We offer companies product with great price and premium quality, skilled operation is our work, we adhere to honesty and superior faith working attitude. We are looking forward to cooperating with you and providing our best services for you, as well as our carbon rapid prototyping, Aerospace Manufacturing,SWISS LATHE PROCESSING. We are eager to cooperate with foreign companies which care much on the real quality, stable supply, commercial esteem. We supply our carbon rapid prototyping worldwide, with markets including Southeast Asia, West Africa, Mexico, Western Europe, etc.

Other Categories From Top Prototype

Why Choose Top Prototype Carbon Rapid Prototyping ?

Carbon rapid prototyping leverages cutting-edge digital light synthesis (DLS) technology to accelerate the design-to-production pipeline. This innovative approach utilizes a photopolymerization process that enables the creation of high-precision, complex geometries with exceptional surface finish and mechanical properties. By employing a continuous liquid interface production (CLIP) technique, Carbon’s method reduces lead times significantly, allowing for rapid iterations and modifications during the development phase. This not only enhances product innovation but also lowers costs associated with traditional prototyping methods. The versatility of Carbon’s materials further supports a range of applications across industries, from automotive to consumer goods, making it an indispensable tool for engineers and designers striving for efficiency and excellence in modern manufacturing.

Energy Efficiency Of Carbon Rapid Prototyping

In the realm of rapid prototyping, carbon-based technologies emerge as not only innovative but also energy-efficient solutions. Leveraging the unique properties of carbon, these methods significantly reduce material waste and energy consumption during production. Oral tradition highlights the importance of sustainable practices, and carbon rapid prototyping embodies this ethos by transforming ideas into tangible products with minimal environmental impact. As industries seek to balance creativity with ecological responsibility, carbon rapid prototyping stands out as a beacon of efficiency in modern manufacturing.

Carbon Rapid Prototyping Unique Features

- Speed: Carbon rapid prototyping significantly reduces the time from design to production, enabling faster iterations and quicker market entry.

- Precision: Utilizes advanced digital light synthesis technology for highly accurate and detailed prototypes.

- Material Variety: Offers a range of material options, including elastomers and rigid resins, catering to diverse applications.

- Scalability: Allows for easy scaling from small prototypes to larger production runs without compromising quality.

- Sustainability: Minimizes waste through efficient use of materials, contributing to eco-friendly production practices.

- Customization: Facilitates unique, tailored designs to meet specific client needs and preferences.

- Integrated Workflows: Seamlessly integrates with existing CAD software, enhancing design flexibility and collaboration.

Environmental Impact From Top Prototype

- Carbon Rapid Prototyping: A cutting-edge technology that accelerates product development with minimal environmental impact.

- Material Efficiency: Utilizes advanced materials that reduce waste compared to traditional prototyping methods.

- Energy Consumption: Designed for lower energy use in production, helping to decrease the carbon footprint.

- Recyclability: Many components used are recyclable, promoting a circular economy.

- Reduced Transportation Emissions: Localized production diminishes the need for long-distance shipping.

- Innovation for Sustainability: Encourages the design of eco-friendly products from the outset, aligning with modern environmental goals.

2 thoughts on “Carbon Rapid Prototyping”

They’re incredibly trustworthy and great customers, and working together on carbon rapid prototyping has been a real pleasure!

Throughout our collaboration, we discovered that they have a fantastic quality management system in place. Their thorough inspections keep the quality of carbon rapid prototyping consistently top-notch!

Comments are closed.