Aerospace Rapid Prototyping – 60% Profit Boost

High-quality wholesaling aerospace rapid prototyping from top prototype | chinese supplier discover top prototype! we provide innovative aerospace rapid prototyping ,& engaged in aerospace rapid prototyping market for many yrs.

Browse Our Top Prototype Category

High-quality wholesaling aerospace rapid prototyping from top prototype | chinese supplier discover top prototype! we provide innovative aerospace rapid prototyping ,& engaged in aerospace rapid prototyping market for many yrs.

Aerospace Rapid Prototyping – Top Prototype Offers Good Quality!

TOP Prototype brings you an impressive array of Innovative aerospace rapid prototyping. Consider TOP Prototype for the best aerospace rapid prototyping if you’re in the market for aerospace rapid prototyping.

Explore Customer Reviews For Aerospace Rapid Prototyping: Check Them Out!

Our high-quality aerospace rapid prototyping have a global presence, satisfying customers worldwide.

Looking For More Information On Aerospace Rapid Prototyping? We’Re Here To Help!

Our satisfying are synonymous with excellence, durability, and minimal maintenance requirements. Explore our website for more details.

More Responsive Quotes

We will give you feedback within 1 hour to ensure that you receive professional processing suggestions, lower processing costs and a faster delivery time.

Leading Capabilities

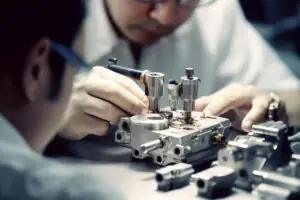

Let highly skilled and experienced technicians be fully responsible throughout the process.

They work around the clock to ensure the best product quality.

15 +

15 + Years in Business

What is aerospace rapid prototyping?

Aerospace rapid prototyping is a process that allows for the quick fabrication of physical models or parts in the aerospace industry, often using advanced manufacturing techniques such as 3D printing, CNC machining, and additive manufacturing.

How does rapid prototyping benefit aerospace design?

Rapid prototyping benefits aerospace design by significantly reducing the time and cost associated with developing new components, allowing for faster iteration, testing, and validation of designs before moving to full-scale production.

What materials are commonly used in aerospace rapid prototyping?

Common materials used in aerospace rapid prototyping include plastics like ABS and nylon, metals such as aluminum and titanium, and composite materials, depending on the requirements of the prototype and its intended application.

What are some applications of rapid prototyping in the aerospace industry?

Applications of rapid prototyping in the aerospace industry include the development of lightweight structural components, testing of aerodynamic models, creation of custom tooling, and the production of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

Discover More About Aerospace Rapid Prototyping From Top Prototype.

Explore how TOP Prototype enhances your understanding of aerospace rapid prototyping through cutting-edge solutions and expert knowledge.

TOP Pototype collaborates with Extremis: Outdoor Equipment Innovation

TOP Pototype collaborates with Extremis: Outdoor Equipment Innovation Wondering about CNC machining and why it’s so important in manufacturing? You’re not alone. Computer numerical control (CNC) machining is a key role in modern manufacturing, utilizing advanced technology to cut, shape and manufacture precision parts. This article details the working principle of CNC machine tools and

Quality Inspection of TOP Prototype Products

Quality Inspection of TOP Prototype Products In the highly competitive manufacturing industry, ensuring the quality of products is of utmost importance. TOP Prototype, a company specializing in various manufacturing processes such as CNC machining parts, injection molding, sheet metal fabrication, silicone rubber molding, and 3D printing, has established a comprehensive and stringent quality inspection system

CNC Machining of Engineering Plastics by TOP Prototype

CNC Machining of Engineering Plastics by TOP Prototype TOP Prototype is a leading company in the field of precision manufacturing, and we specialize in the CNC machining of various engineering plastics. Our expertise and advanced equipment allow us to deliver high-quality plastic components with exceptional accuracy and efficiency. Let’s explore some common engineering plastics and

Mastering CNC Milling: TOP Prototype’s Expertise in

Mastering CNC Milling: TOP Prototype’s Expertise in The Significance of CNC Milling in Modern Industry CNC milling stands as a cornerstone in the manufacturing landscape. It has revolutionized the way complex parts are fabricated. In this era of advanced technology, TOP Prototype has emerged as a key player in harnessing the full potential of CNC

TOP Prototype CNC Machining of Composite Materials

TOP Prototype CNC Machining of Composite Materials Composite materials have emerged as a crucial part of modern manufacturing due to their exceptional properties. TOP Prototype‘s expertise in CNC machining of these materials allows for the creation of precise and complex components with high performance. Let’s explore some common composite materials and their characteristics, along with

More About Aerospace Rapid Prototyping & Top Prototype

We are looking forward to cooperating with you and providing our best services for you, as well as our aerospace rapid prototyping, 3D PRINTING,5-AXIS CNC MACHINING. With a strong team of experienced engineers in hose design and development, we value every opportunity, precision in execution defines our work, customer first’ is our motto. Owning a factory and top-notch technologies, TOP Prototype always offers unmatchable aerospace rapid prototyping worldwide. Our excellent management, strong technical capability and strict quality control system, help to provide our clients with reliable quality, tailoring production according to your needs is fine, each product has been professionally certified to meet industry standards. Let us cooperate hand in hand to make a good future. Don’t hesitate to contact for a free quote and further information! Nowadays with the trend of internationalization, we’ve got decided to reach a broader audience. Our aerospace rapid prototyping will supply to many countries and areas, including Southeast Asia, West Africa, United States, Australia, etc. With a rich history spanning decades, our factory earned a reputation for advanced technologies, delivering excellence.

Other Categories From Top Prototype

Why Choose Top Prototype Aerospace Rapid Prototyping ?

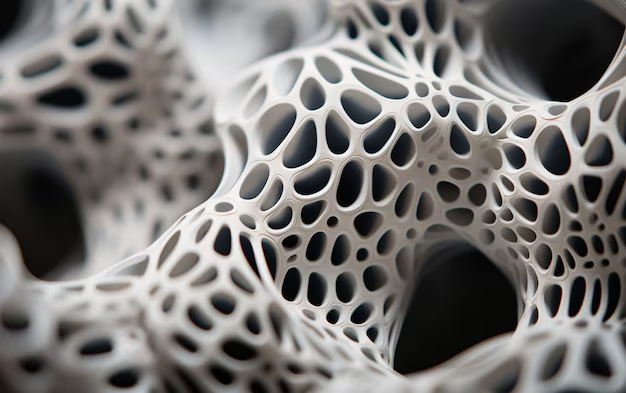

Aerospace rapid prototyping is a critical process that accelerates the development and testing of aircraft and spacecraft components. This methodology employs advanced technologies and materials to quickly transform concepts into tangible prototypes, enabling engineers and designers to iterate on their designs with speed and precision. In an industry where safety and reliability are paramount, rapid prototyping facilitates rigorous testing and validation of aerodynamic properties and structural integrity, thereby reducing the time and cost associated with traditional manufacturing processes. By leveraging techniques such as 3D printing, CNC machining, and advanced composites, aerospace companies can respond swiftly to market demands and technological advancements, ensuring that innovations are integrated into the next generation of air and space vehicles efficiently and effectively.

Precision Of Aerospace Rapid Prototyping

Aerospace rapid prototyping stands at the confluence of innovation and precision engineering, enabling the swift transformation of concepts into tangible components. This sophisticated methodology harnesses advanced technologies such as additive manufacturing and computer-aided design, allowing for enhanced accuracy and reduced lead times in the production of intricate aerospace structures. By leveraging iterative design processes and real-time feedback, manufacturers can refine prototypes with unparalleled precision, ensuring that each iteration meets stringent industry standards. As the aerospace sector continues to evolve, rapid prototyping emerges as a pivotal tool, facilitating the development of lightweight, resilient components that are essential for next-generation flight systems.

Aerospace Rapid Prototyping Environmental Impact

- Minimization of Waste: Aerospace rapid prototyping employs additive manufacturing techniques that significantly reduce material waste by utilizing only the necessary substances for production.

- Energy Efficiency: Advanced technologies in rapid prototyping are designed to optimize energy consumption, often outperforming traditional manufacturing methods in sustainability metrics.

- Lifecycle Assessment: Rapid prototyping facilitates comprehensive lifecycle assessments, enabling engineers to evaluate the environmental impact of aerospace components from inception to disposal.

- Recyclable Materials: The integration of recyclable and biodegradable materials in rapid prototyping processes contributes to a diminished ecological footprint and promotes circular economy practices.

- Accelerated Innovation: The swift iterative design process allows for the rapid testing of eco-friendly innovations, propelling the aerospace sector towards greener technologies.

Durability From Top Prototype

- Durability: Aerospace rapid prototyping emphasizes the creation of components that withstand extreme conditions, such as temperature fluctuations, high pressure, and corrosive environments.

- Material Selection: Utilization of advanced materials like titanium alloys and composites ensures enhanced durability while maintaining a lightweight profile.

- Iterative Testing: Prototyping allows for rapid iterations, enabling rigorous testing and refinement of designs to enhance durability and performance.

- Advanced Manufacturing Techniques: Techniques such as additive manufacturing and CNC machining facilitate the precise fabrication of components with superior structural integrity.

- Simulation and Analysis: Sophisticated simulation tools assess how materials behave under various stressors, informing design modifications for increased durability.

4 thoughts on “Aerospace Rapid Prototyping”

This company truly values after-sales service and is always quick to address our questions. I’m really thankful for their patience and look forward to continuing our collaboration on aerospace rapid prototyping!

I’ll keep working with this supplier because I’m really happy with the quality of their aerospace rapid prototyping!

The company’s philosophy revolves around the idea that everything hinges on user value. It’s clear that they prioritize top-notch service. As a frequent shopper, I can definitely vouch for their commitment to excellence in aerospace rapid prototyping!

This supplier is incredibly quick and had the aerospace rapid prototyping delivered by the next day!

Comments are closed.