CNC Machining Services

Main Types for CNC Machining

Online CNC Machining Services

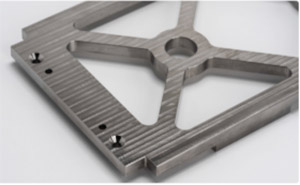

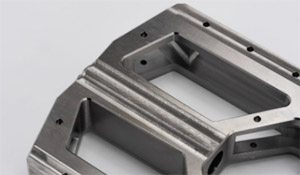

Custom CNC machining parts machining services for rapid prototyping, new product introduction and low-volume production.

- Instant Quote within 4 Hours

- Lead time as fast as 1 day

- Tolerance as tight as ±0.02 mm

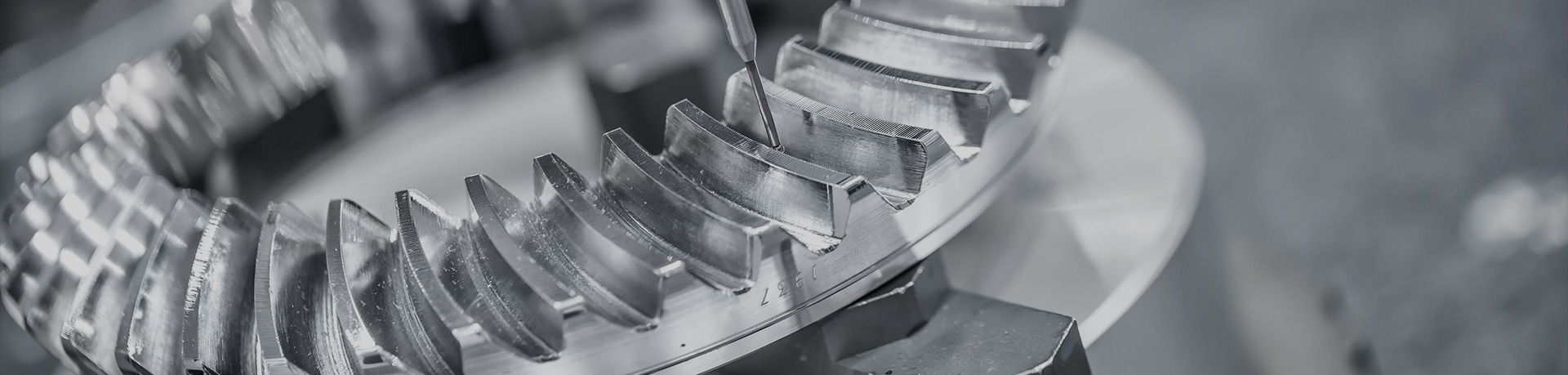

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to a platform inside the milling machine. The cutter is a cutting tool with sharp teeth that is also secured in the milling machine and rotates at high speeds. By feeding the workpiece into the rotating cutter, material is cut away from this workpiece in the form of small chips to create the desired shape.

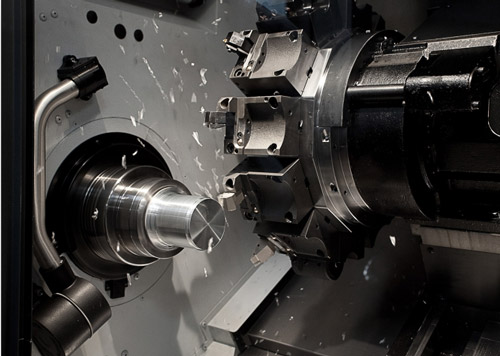

Turning is a form of machining, a material removal process, which is used to create rotational parts by cutting away unwanted material. The turning process requires a turning machine or lathe, workpiece, fixture, and cutting tool. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to the turning machine, and allowed to rotate at high speeds. The cutter is typically a single-point cutting tool that is also secured in the machine, although some operations make use of multi-point tools. The cutting tool feeds into the rotating workpiece and cuts away material in the form of small chips to create the desired shape.

Choose from a broad range of surface finishes

| As machined (Ra 3.2μm / Ra 126μin) | This is our standard finish. Parts are machined and deburred, sharp edges are chamfered. |

|

| Smooth machining (Ra 1.6μm / Ra 63μin) | Smooth machining is like an ‘As machined’ finish but with slightly less evident machine marks. Parts are machined at a lower feed, no hand polishing is applied. |

|

| Brushed (Ra 1.2μm / Ra 47μin) | Parts are brushed with a #400 - 600 grit. Ideal to reduce the surface roughness of the part. |

|

| Powder coated | Powder coating is a strong, wear-resistant finish that is compatible with all metal materials. |

|

| Bead blasted | Parts are bead blasted with glass beads which results in a grainy texture. |

|

| Polishing (Ra 0.8μm / Ra 32μin) | Parts are manually polished in multiple directions. Surface is smooth and slightly reflective. |

|

| Black oxide | Applicable on steels, black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection. |

|

| Chromate Conversion Coating | Parts are machined and a chromate conversion coating is applied. Ideal to increase the corrosion resistance of the part while maintaining its conductive properties. RoHS compliant. |

|

| As machined + Anodized type III (Hardcoat) | Parts are machined and an anodizing type III coating is directly applied to the surface. Ideal to improve corrosion and wear resistance of components. |

|

| Bead blasted + Anodized type II (Matte) | Parts are bead blasted and anodized type II. Ideal for increasing the corrosion resistance of the part. Results in naturally matte colors. For glossy colors, please select the brushed anodizing option. |

|

| Brushed + Electropolished (Ra 0.8μm / Ra 32μin) | Parts are brushed and electropolished. Ideal to reduce the micro-roughness of the part. |

|

Standard tolerances for CNC machining

The table below summarizes the standard tolerances of the parts produced by certified Hubs Manufacturing Partners. We follow ISO 2768 standards for CNC Machining.

| Limits for nominal size | Plastics (ISO 2768- m) | Metals (ISO 2768- f) |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm |

Larger parts are reviewed on request, submit an here order to begin.

Size limitations for CNC machining

| Maximal part size | 1000 mm (40in) |

| Minimal part size | 0.5 mm (0.02 in) |

| Minimal diameter | 0.3 mm (0.01 in) |

How we ensure high quality machined parts

Every order includes our standard inspection report. Further reports and certifications are available on request, submit an order to begin.

|

Standard |

On request |

|

|